A chemical nickel-gold process with ultra-low nickel corrosion

An electroless nickel-gold and nickel corrosion technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problem that the performance has not been greatly improved, and achieve low corrosion potential and corrosion current density, The effect of long replacement cycle and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

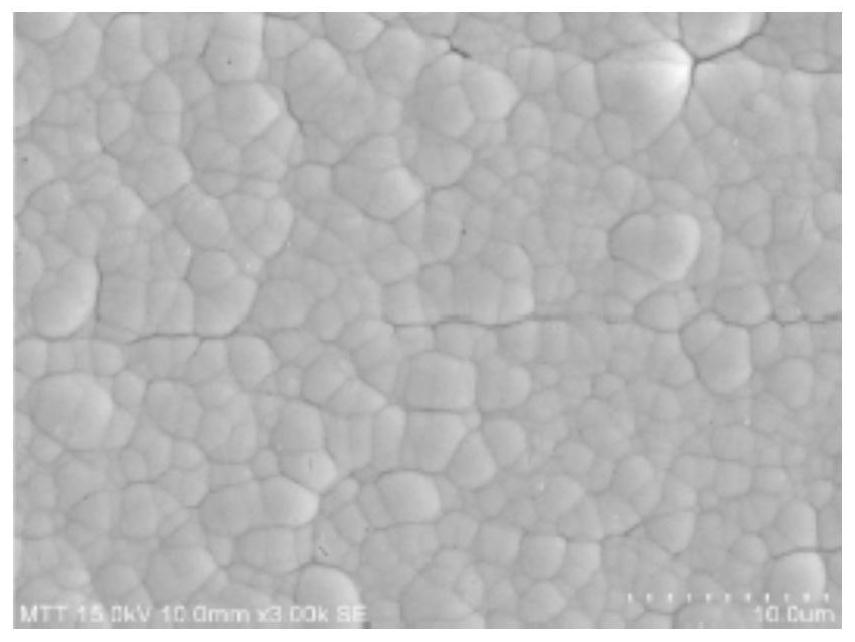

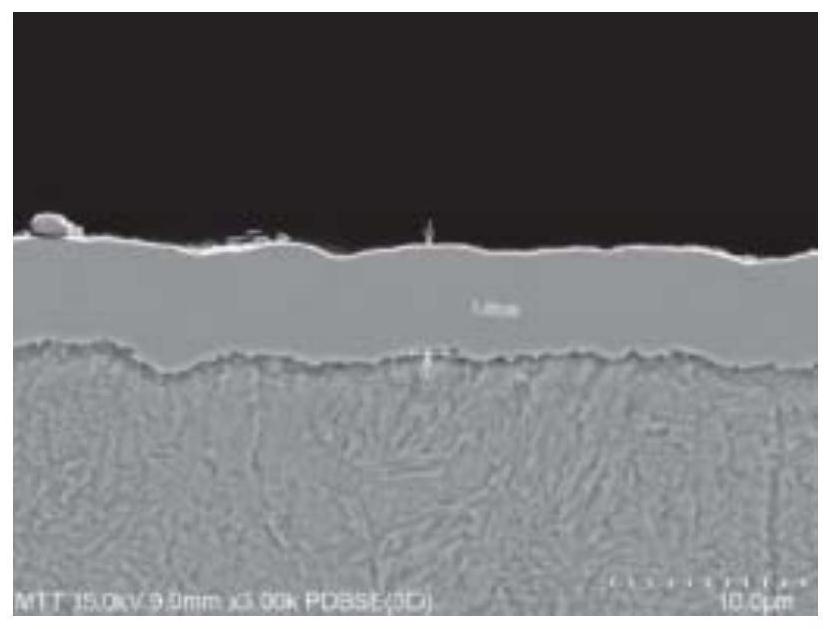

Image

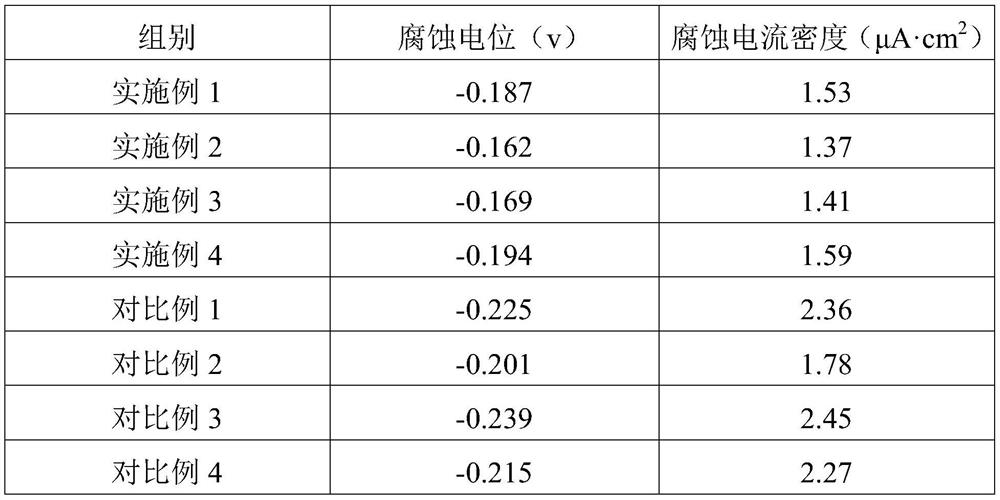

Examples

Embodiment 1

[0055] A chemical nickel-gold process for ultra-low nickel corrosion, comprising the following steps:

[0056] S1) Pretreatment: take the substrate and carry out the steps of degreasing, washing twice, micro-etching, washing twice, pickling, washing twice, pre-soaking, washing twice, activation, washing twice and post-dip step, to obtain the pre- processing substrates;

[0057] Degreasing is soaking for 4 minutes with an aqueous solution containing 5wt% phosphoric acid and 5wt% sulfuric acid. The microetching is soaked in an aqueous solution containing 5wt% sulfuric acid and 5wt% sodium persulfate for 1 min. Pickling, pre-soaking and post-soaking are all soaked in an aqueous solution containing 0.5wt% sulfuric acid for 1 min. Activation is soaking for 1 min with an aqueous solution containing 0.5 wt % sulfuric acid and 20 mg / L palladium sulfate.

[0058] S2) Electroless nickel plating; immersing the pretreated copper sheet in step S1 in an electroless nickel plating solutio...

Embodiment 2

[0066] A chemical nickel-gold process for ultra-low nickel corrosion, comprising the following steps:

[0067] S1) Pretreatment: take the substrate and carry out degreasing, water washing twice, micro-etching, water washing twice, pickling, water washing three times, pre-soaking, water washing twice, activation, water washing twice and post-soaking steps to obtain the pre- processing substrates;

[0068] Oil removal is soaked for 5 minutes with an aqueous solution containing 5wt% phosphoric acid and 5wt% sulfuric acid. The microetching is soaked in an aqueous solution containing 5wt% sulfuric acid and 5wt% sodium persulfate for 1 min. Pickling, pre-soaking and post-soaking are all soaked in an aqueous solution containing 0.5wt% sulfuric acid for 1 min. Activation is soaking for 1 min with an aqueous solution containing 0.5 wt % sulfuric acid and 25 mg / L palladium sulfate.

[0069] S2) Electroless nickel plating; immersing the pretreated copper sheet in step S1 in an electro...

Embodiment 3

[0077] A chemical nickel-gold process for ultra-low nickel corrosion, comprising the following steps:

[0078] S1) Pretreatment: Take the substrate and carry out degreasing, water washing twice, micro-etching, water washing three times, pickling, water washing three times, pre-soaking, water washing three times, activation, water washing two times and post-soaking steps successively to obtain the pre- processing substrates;

[0079] Oil removal is soaked for 5 minutes with an aqueous solution containing 6wt% phosphoric acid and 5wt% sulfuric acid. The microetching is soaked in an aqueous solution containing 5wt% sulfuric acid and 8wt% sodium persulfate for 1 min. Pickling, pre-soaking and post-soaking are all soaked in an aqueous solution containing 0.5wt% sulfuric acid for 1.5min. Activation is soaking for 1 min with an aqueous solution containing 1 wt % sulfuric acid and 25 mg / L palladium sulfate.

[0080] S2) Electroless nickel plating; immersing the pretreated copper sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com