Crimping device for sewing machine with thread trimming function

A technology of crimping device and sewing machine, which is applied to the protection device of the sewing machine, the components of the sewing machine, the mechanism for cutting the thread in the sewing machine, etc., and can solve the problems that the crimping device does not have the function of cutting the thread, is cumbersome, and the scissors fall on the place, etc. Achieve the effects of easy replacement of shearing blades, improved safety, and improved structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

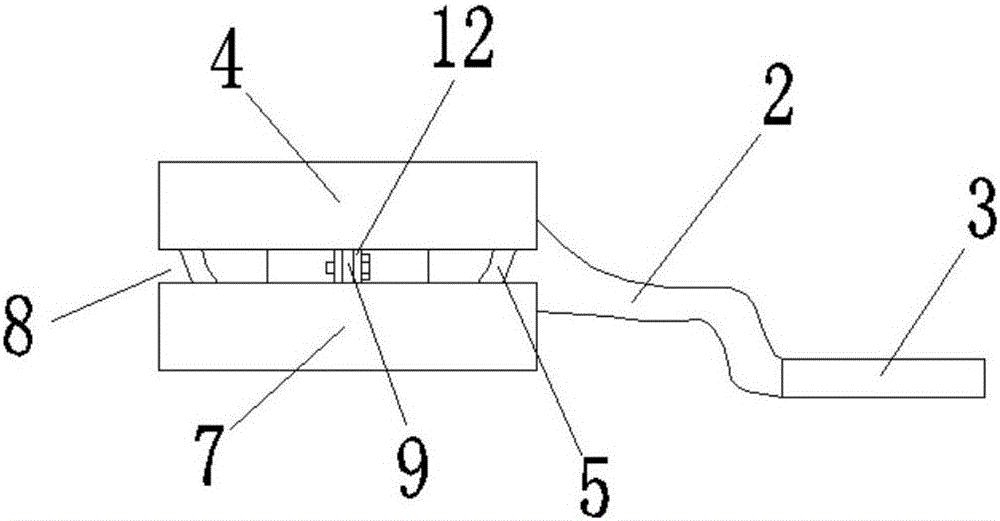

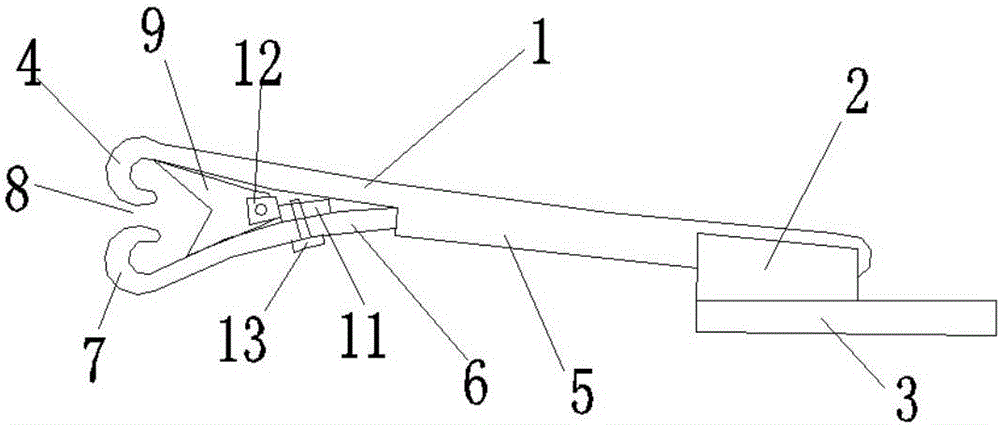

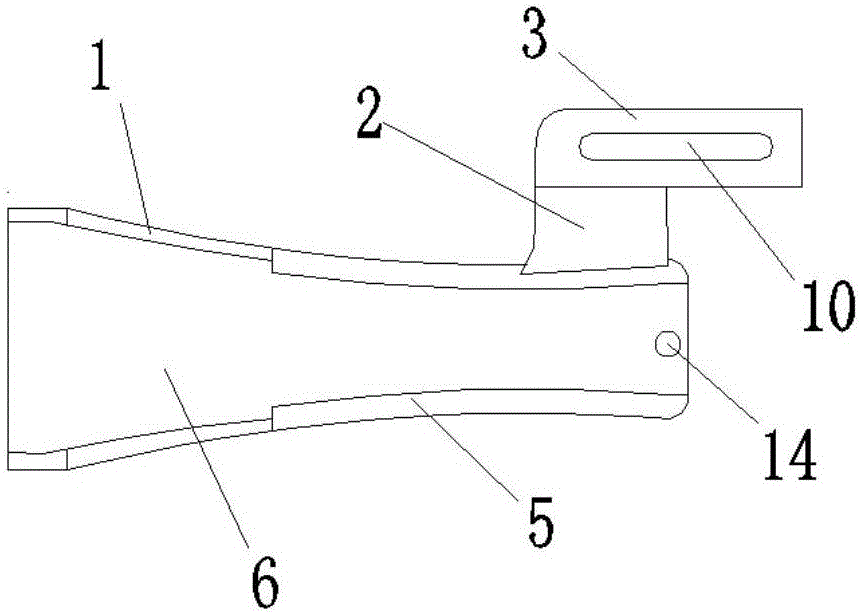

[0018] Such as figure 1 , figure 2 , image 3 As shown, a sewing machine curling device with a thread trimming function includes a curling plate 1, a connecting plate 2, and a mounting plate 3. The front end of the curling plate 1 is provided with a downwardly turned arc-shaped plate A4, and the curling plate The left and right sides of 1 are turned to the bottom and inside to form curling grooves 5, and a fixing plate 6 is arranged between the curling grooves 5 on the left and right sides of the curling plate 1, and the fixing plate 6 is connected with the curling plate 1 through bolts B14, and the fixing plate The front end of 6 is provided with an upwardly turned arc-shaped plate B7, and the arc-shaped plate B7 is located below the arc-shaped plate A4. There is a gap area 8 between the arc-shaped plate A4 and the arc-shaped plate B7. The front end of the curling plate 1 and the front end of the fixed plate 6 A blade mounting seat 11 is provided between them, and the blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com