Full-automatic washing machine

A fully automatic washing machine and washing machine technology, which is applied to other washing machines, washing machines with containers, washing machine control devices, etc., can solve the problems of complex assembly of the whole machine, difficulty in adjusting the program, and high cost, and achieve convenient use, simple appearance, and compatibility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

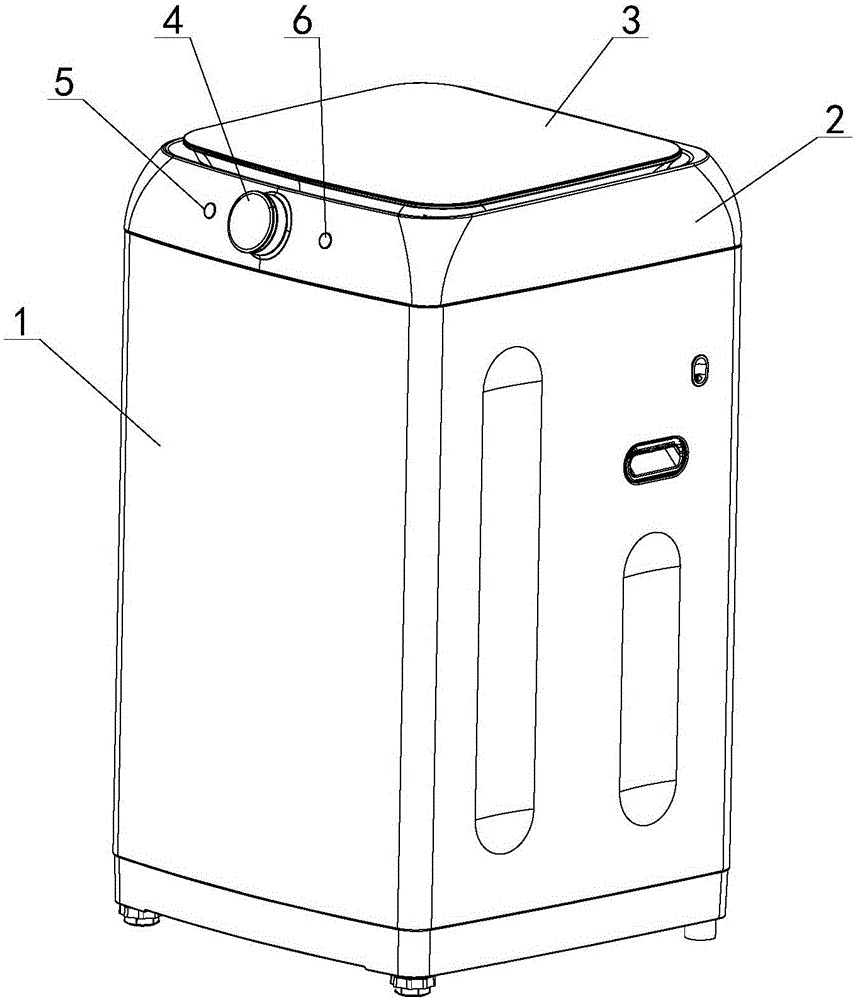

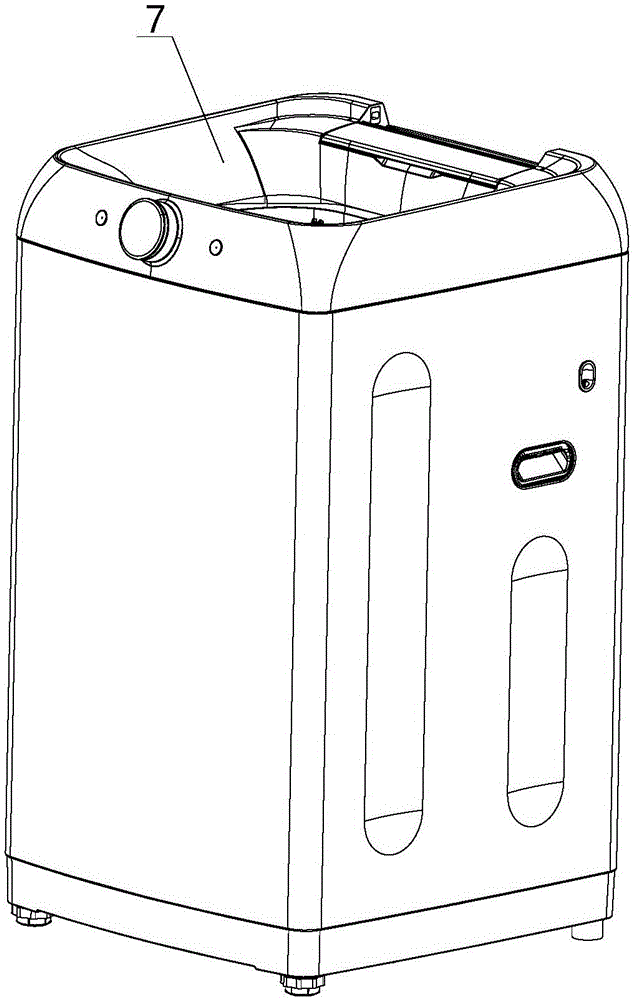

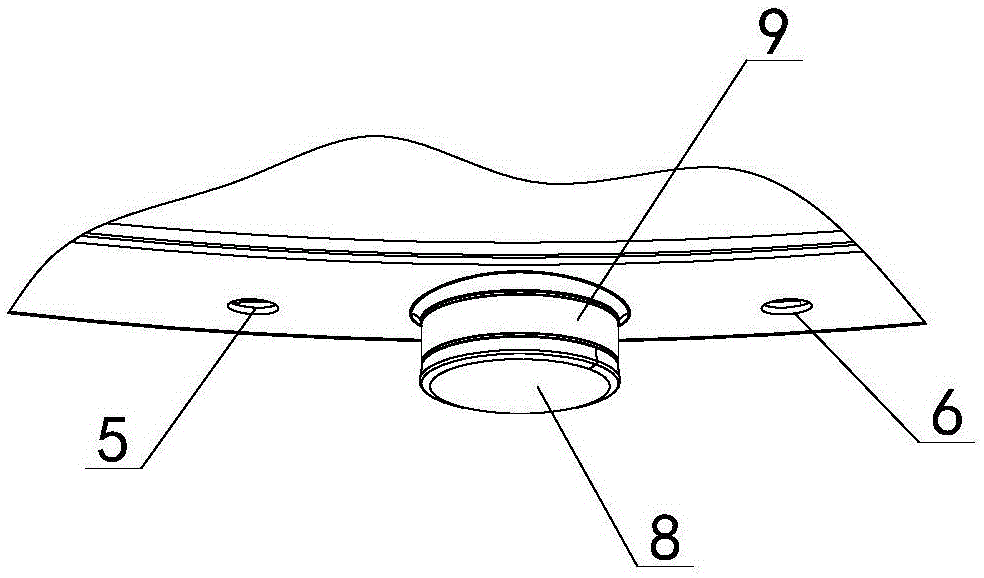

[0029] Figures 1 to 2 It is a schematic structural view of the fully automatic washing machine according to a specific embodiment of the present invention, which includes a housing 1, a control panel base 2 and an upper cover 3, the control panel base 2 is located on the top of the housing 1, and a clothes input device is arranged on it. 7, the upper cover 3 is rotatably arranged on the control panel base 2 to open or close the clothes input port 7, and the corresponding control panel base 2 is used to accommodate the corresponding control circuit board of the whole machine. The conventional control and display device is installed on its upper surface, which is different from the conventional fully automatic washing machine. The washing machine according to the present invention is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com