A prestressed self-resetting damage controllable assembled swing wall

A prestressed, self-resetting technology, applied in the direction of walls, buildings, building types, etc., can solve the problems of difficult application in the field of structural reinforcement, insufficient concept of building industrialization, and difficult to achieve rapid repair, achieving convenient installation, reducing structural rigidity, The effect of reducing residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

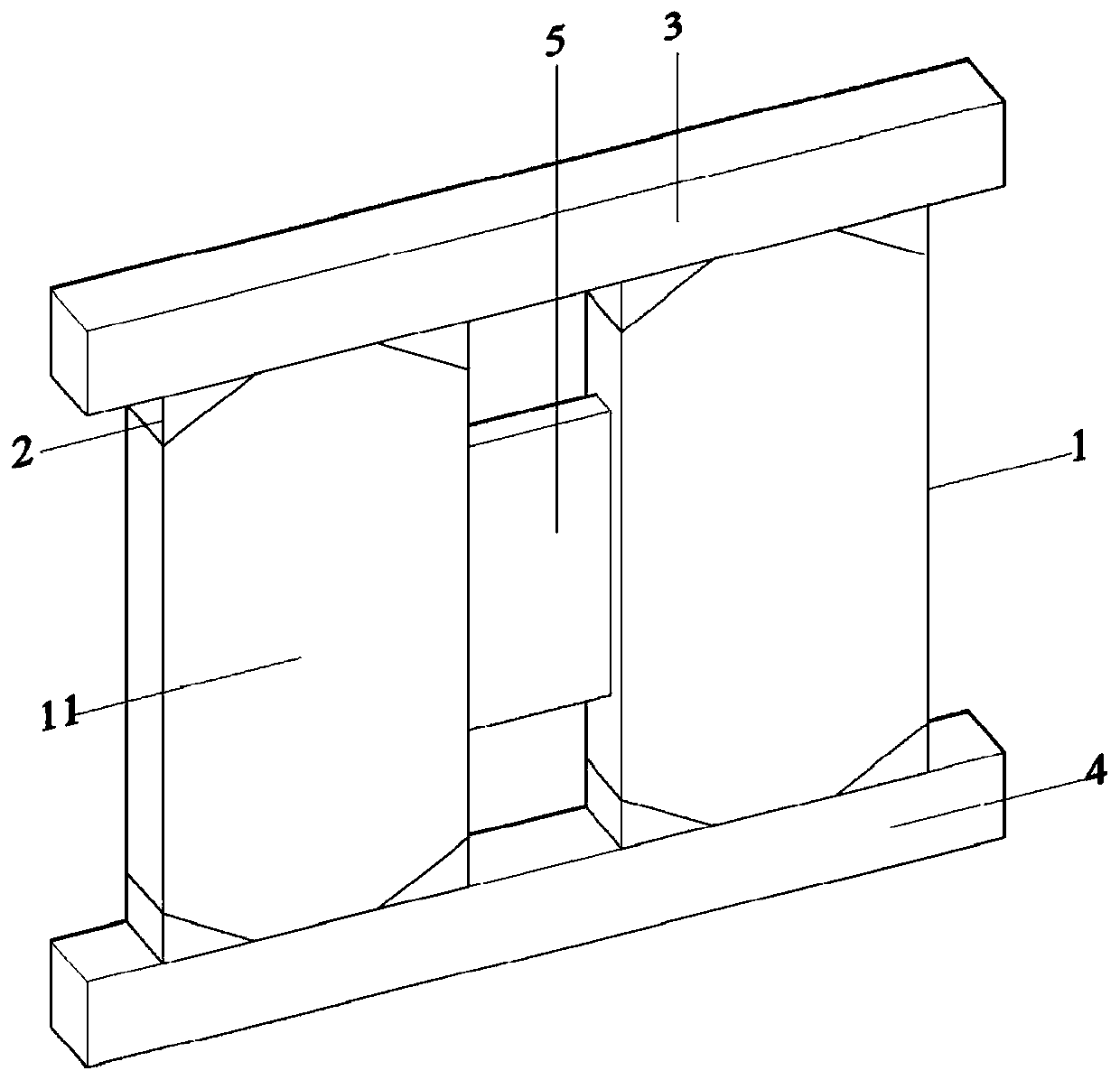

[0039] like Figure 1 to Figure 2 The present invention shown includes at least one assembly unit, and the assembly unit includes at least two prefabricated walls 1, upper connecting beams 3 and lower connecting beams 4, energy dissipation damping 5, unbonded prestressed tendons 6 and other parts. The prefabricated wall body includes a prefabricated reinforced concrete main body 11 and corner deformation blocks 2 . The center of the prefabricated reinforced concrete body 11 of the prefabricated wall 1 reserves an unbonded prestressed tendon tunnel 10, and the four corners are triangular corner deformation blocks 2, and the overall appearance of the two prefabricated walls 1 is a regular cuboid. The deformed blocks 2 at the four corners of the wall are elastic or elastoplastic materials with a lower modulus of elasticity than concrete and higher ductility than concrete, and are connected to the prefabricated reinforced concrete main body 11 through slots. The positions where t...

Embodiment 2

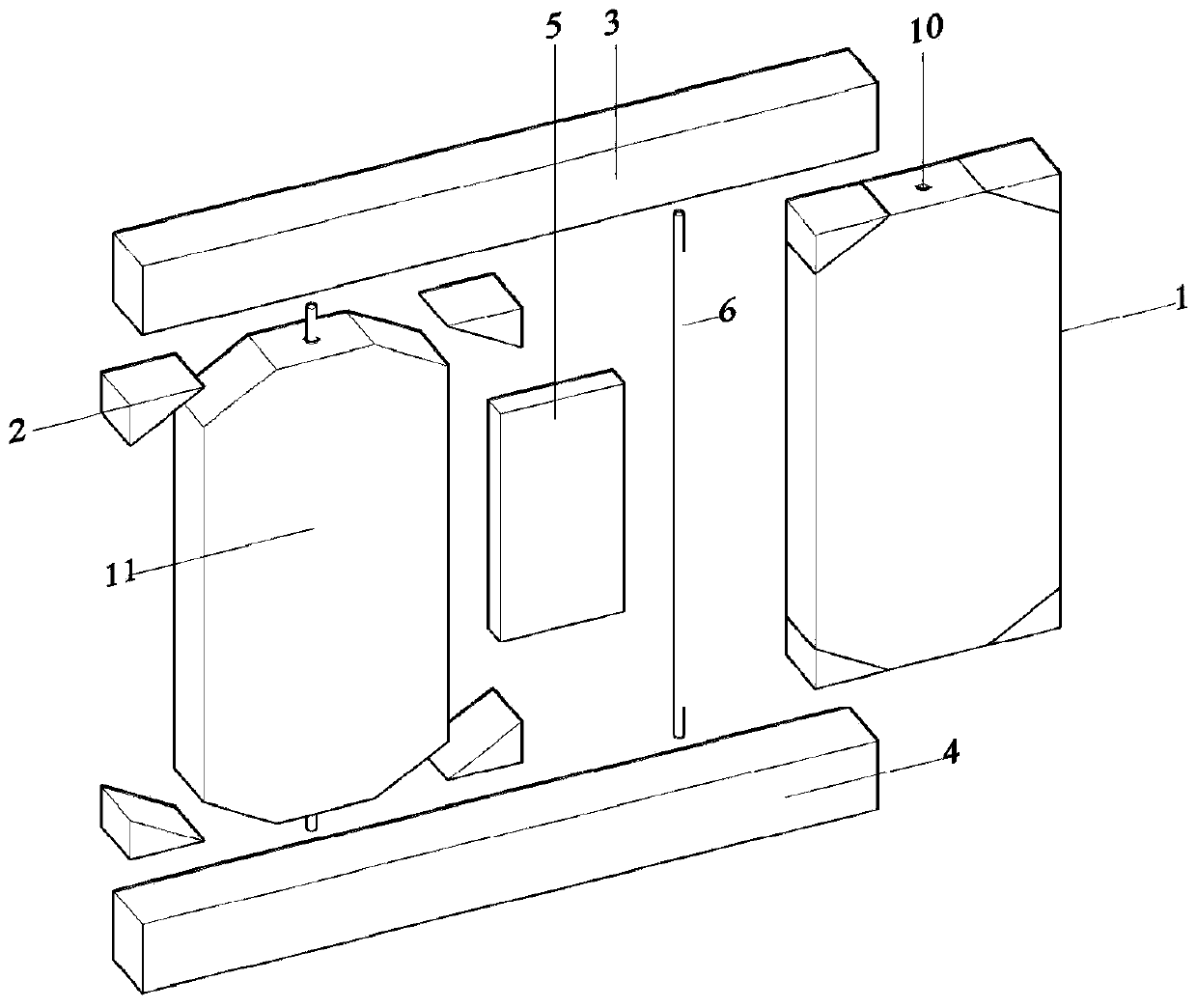

[0041] like Figures 5 to 6As shown, the present invention includes at least one assembly unit, and the assembly unit includes at least two prefabricated walls 1, upper connecting beam 3 and lower connecting beam 4, energy dissipation damping 5, unbonded prestressed tendons 6 and other parts. The prefabricated wall body includes a prefabricated reinforced concrete main body 11 and corner deformation blocks 2 . The center of the prefabricated reinforced concrete body 11 of the prefabricated wall 1 reserves an unbonded prestressed tendon tunnel 10, and the four corners are triangular corner deformation blocks 2, and the overall appearance of the two prefabricated walls 1 is a regular cuboid. The deformed blocks 2 at the four corners of the wall are elastic or elastoplastic materials with a lower modulus of elasticity than concrete and higher ductility than concrete, and are connected to the prefabricated reinforced concrete main body 11 through slots. The positions where the en...

Embodiment 3

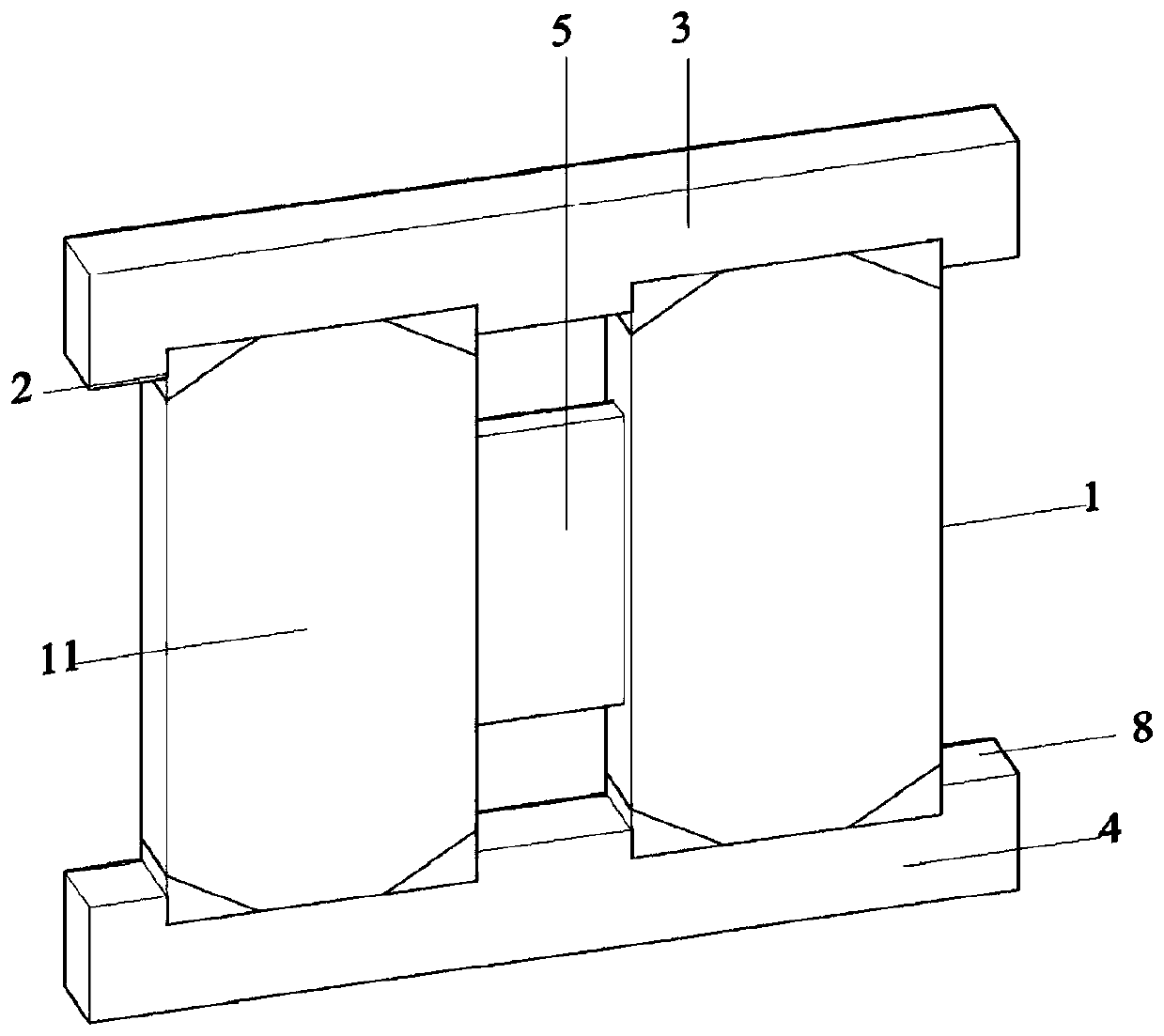

[0043] like Figure 3 to Figure 4 As shown, the present invention includes at least one assembly unit, and the assembly unit includes at least two prefabricated walls 1, upper connecting beam 3 and lower connecting beam 4, energy dissipation damping 5, unbonded prestressed tendons 6 and other parts. The prefabricated wall body includes a prefabricated reinforced concrete main body 11 and corner deformation blocks 2 . The center of the prefabricated reinforced concrete body 11 of the prefabricated wall 1 reserves an unbonded prestressed tendon tunnel 10, and the four corners are triangular corner deformation blocks 2, and the overall appearance of the two prefabricated walls 1 is a regular cuboid. The deformed blocks 2 at the four corners of the wall are elastic or elastoplastic materials with a lower modulus of elasticity than concrete and higher ductility than concrete, and are connected to the prefabricated reinforced concrete main body 11 through slots. The positions where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com