Roller pin bush and auxiliary assembling structure thereof

A needle roller and bushing technology, which is applied in the field of bushings, can solve the problems of high bushing friction and low bushing bearing capacity, and achieve the effects of reducing friction, reducing energy consumption and improving mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following embodiments illustrate the technical solutions of the present invention in detail. The following embodiments are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, and cannot be construed as limiting the technical solutions of the present invention.

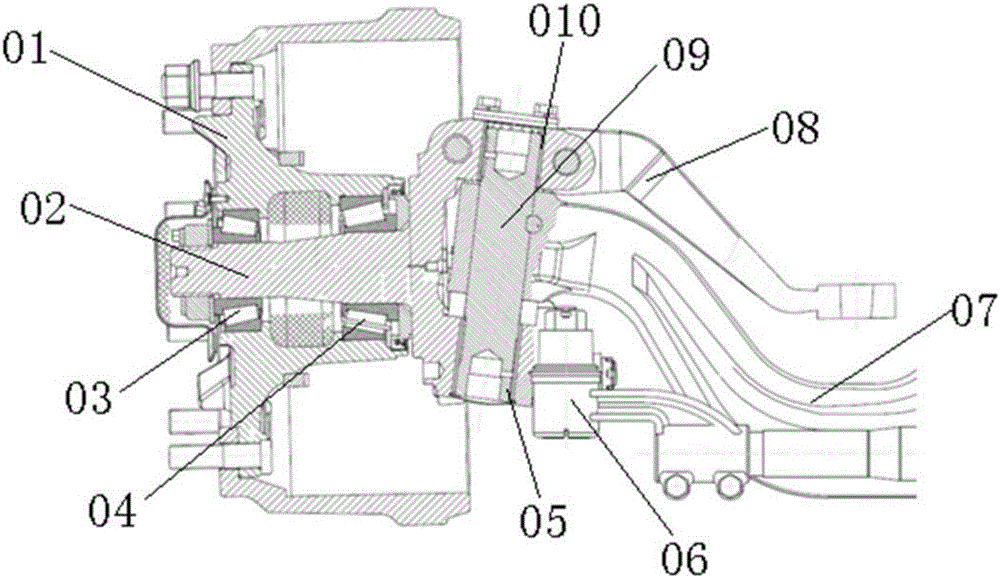

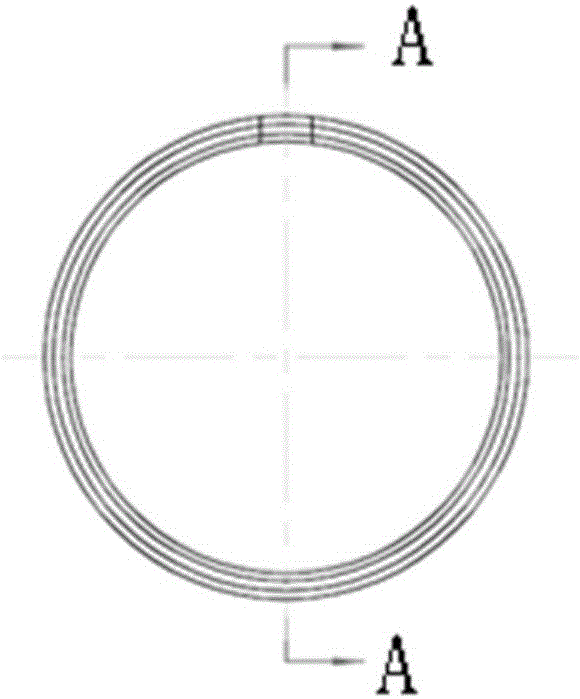

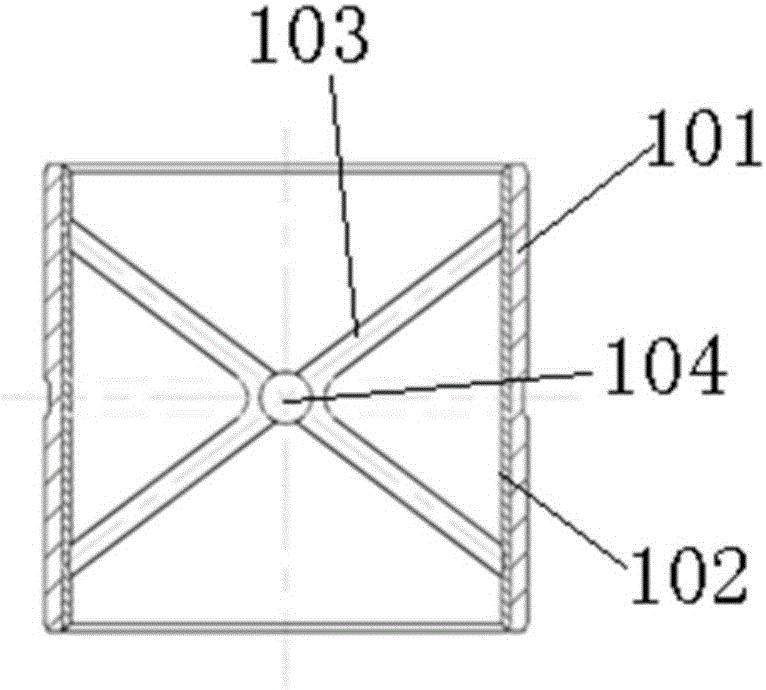

[0050] The invention provides a needle roller bush, such as Figure 5 to Figure 14 As shown, it includes a plurality of needle rollers 1, three end retaining rings, which are respectively a first end retaining ring 2, a second end retaining ring 3, and a third end retaining ring 4; Movably installed between the first end holding ring 2 and the second end holding ring 3; a plurality of the needle rollers 1 are movably installed between the second end holding ring 3 and the first end holding ring 3 The three ends keep between the rings 4.

[0051] The needle roller 1 includes a cylindrical needle roller body and hemispheres at both ends of the cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com