Anti-freezing and waterproof hammer composite high-speed exhaust and intake valve

A composite, anti-freezing technology, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as poor waterproof hammer ability, rupture of valve body and other parts, damage to the float, etc., to eliminate impact and prevent water from freezing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

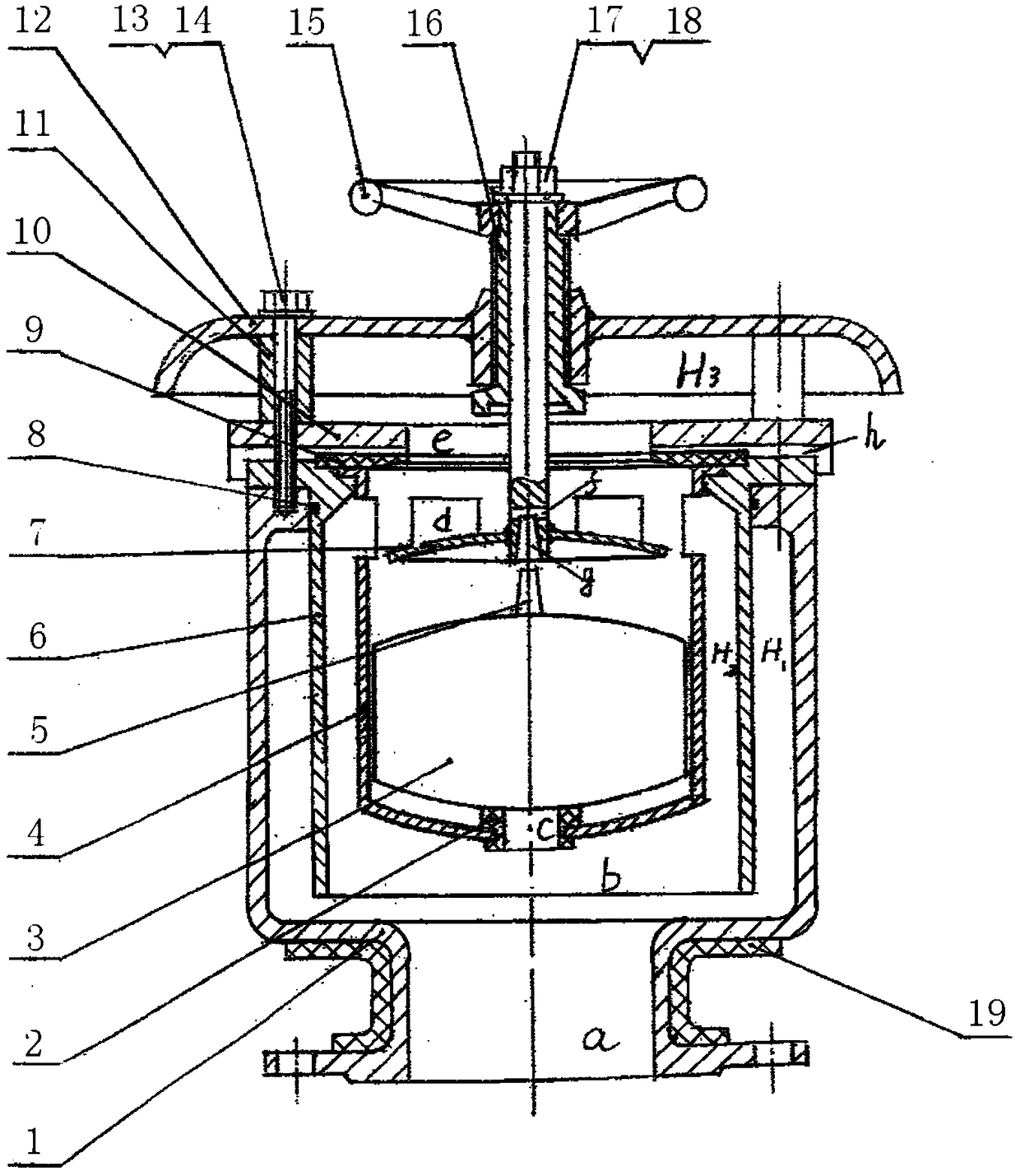

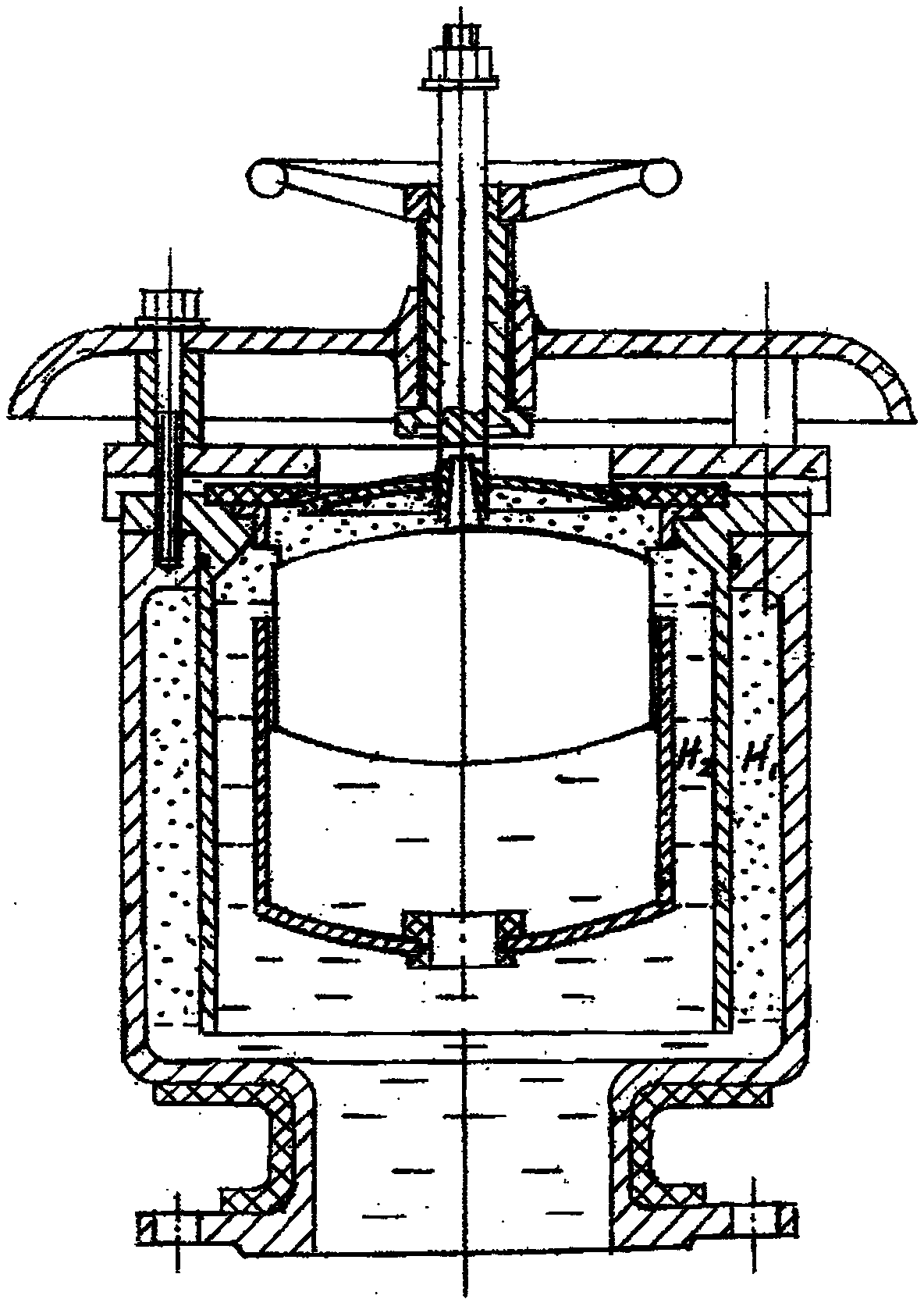

[0024] As shown in the figure, the present invention consists of a valve body 1, an anti-shock pad 2, a floating ball 3, a floating ball cover 4, a conical pin 5, a spacer 6, a lifting cover 7, an O-shaped sealing ring 8, a sealing gasket 9, and a valve cover 10. Sleeve 11, exhaust cover 12, bolt 13, washer one 14, hand wheel 15, push rod 16, nut 17, washer two 18 and other parts; except for sleeve 11, bolt 13, washer one 14, other All parts are located on the same center line after assembly.

[0025] The valve body 1 is a hollow valve housing with a flange at the lower end and a cylinder in the middle. The diameter of the water inlet a at the lower end is smaller than the inner diameter of the cylinder. Flange connection, the lower flange of the inspection valve is connected to the corresponding flange on the pipeline. After the connection, the verticality of the exhaust valve should be controlled within 2°. The upper end surface of the valve body 1 is evenly distributed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com