Novel combustor deslagging furnace door device

A technology of a burner and a door device, which is applied to the door of the combustion chamber, the combustion chamber, and the combustion method, etc., can solve the problems of difficulty in uniformly applying driving force and closing force, damage to the driving transmission system, and hidden dangers in the safety of the slag outlet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

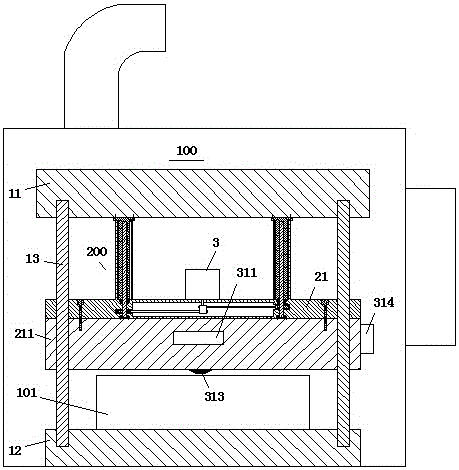

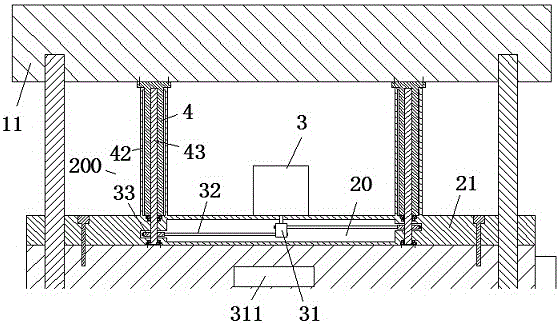

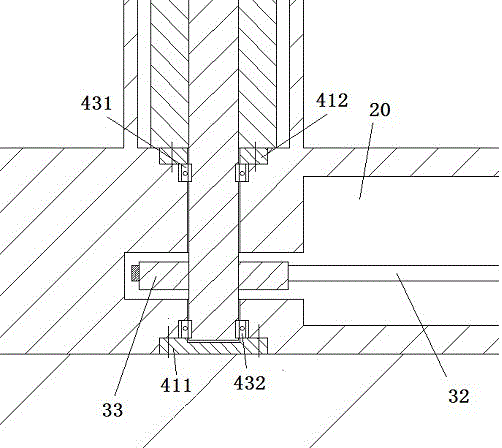

[0010] Combine below Figure 1-3 The present invention will be described in detail.

[0011] According to an embodiment of the present invention, a new type of slagging furnace door device for a burner is used to close and open the slag outlet 101 of the burner 100. The device includes: a solid connection with the body of the burner 100 The upper fixed plate 11 and the lower fixed plate 12, the two guide columns 13 that are fixedly connected between the upper fixed plate 11 and the lower fixed plate 12 and symmetrically arranged on both sides of the slag outlet 101, are formed by the two A sliding furnace door panel 211 guided by a guide column 13, and a driving assembly 200 for driving the sliding furnace door panel 211 to slide up and down, wherein the driving assembly 200 includes two symmetrically fixed on the upper fixing plate 11. A fixed sleeve column 4, a fixed connection bar 21 that is located under the two fixed sleeve columns 4 and is fixedly connected with the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com