Exposure equipment for curved surface products

A curved surface and product technology, applied in the field of exposure equipment for curved surface products, to avoid impact and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Since the material of the exposure sheet used in the existing exposure equipment is glass material, which has a poor fit with curved surface products, it is impossible to complete the exposure processing of curved surface products. In order to solve the above technical problems, this embodiment discloses a Exposure equipment for the exposure process of curved surface products.

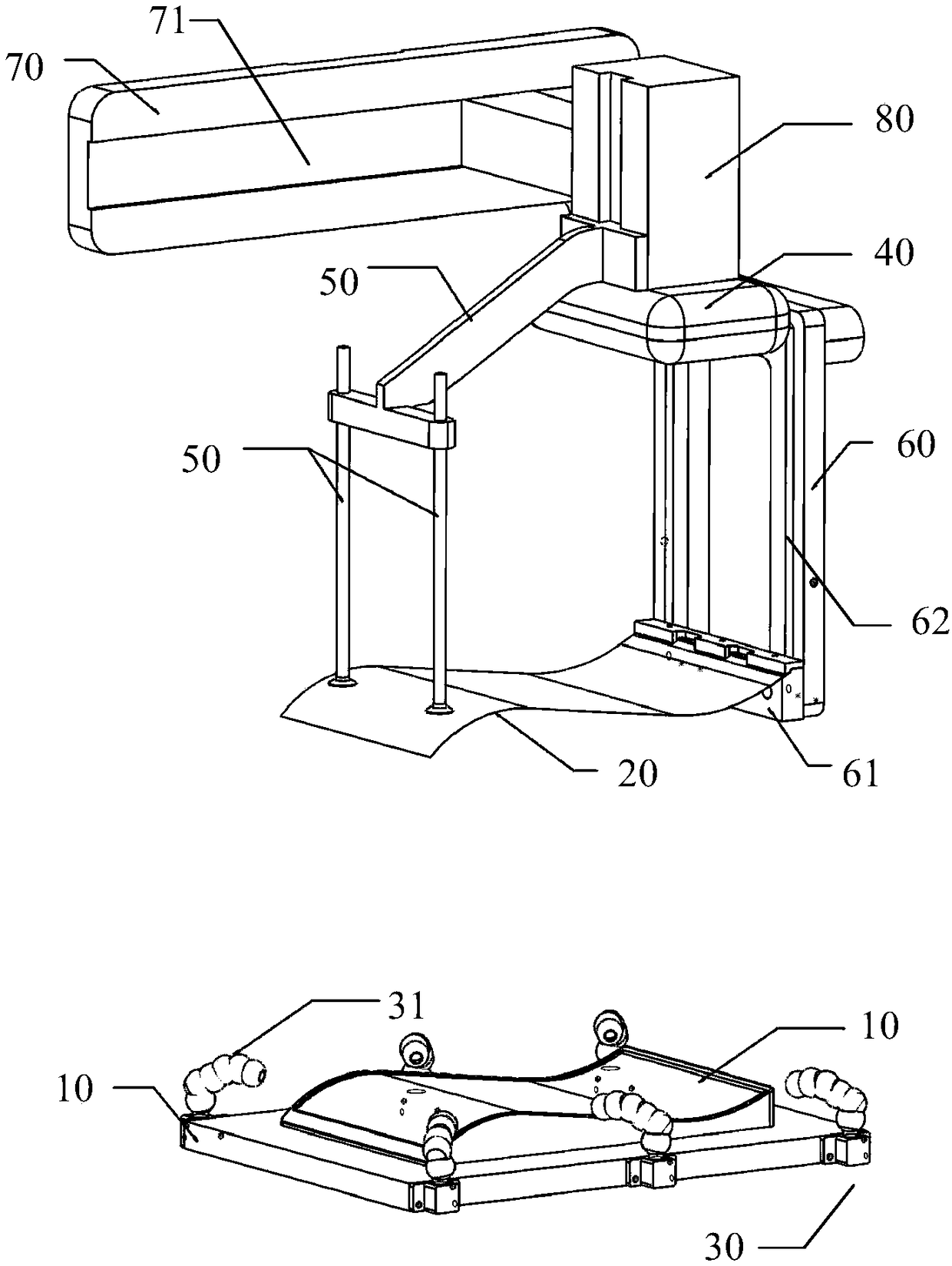

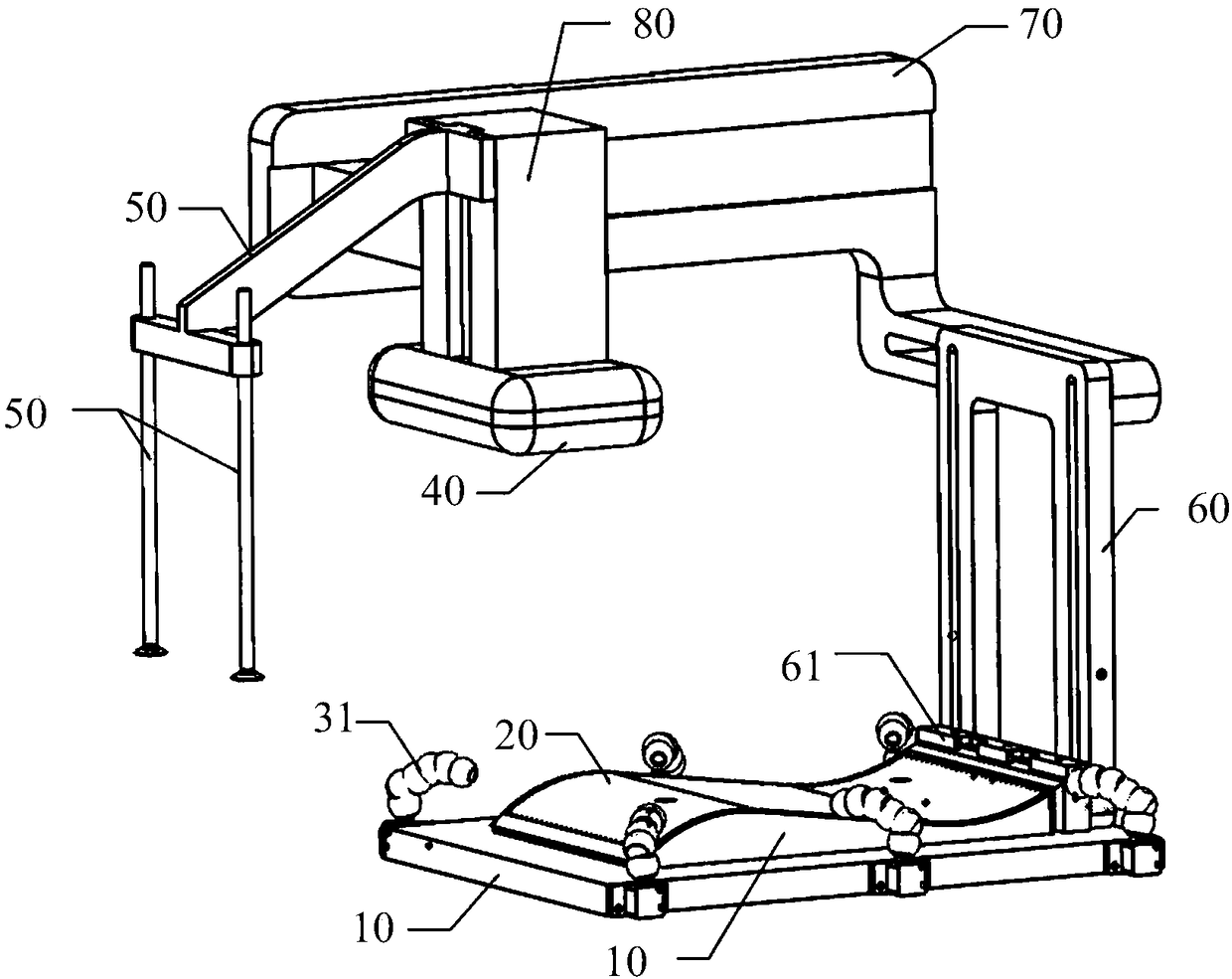

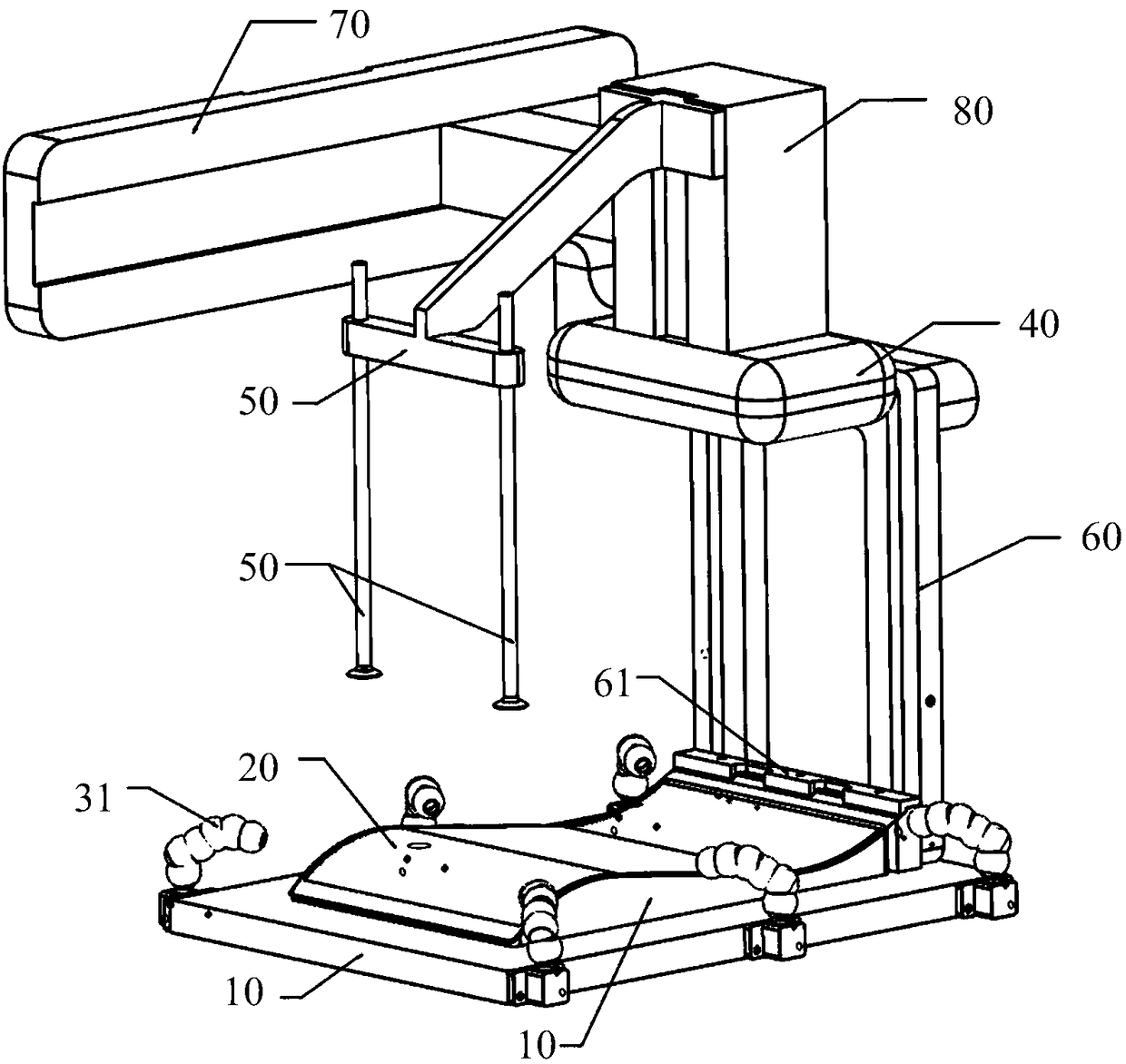

[0022] Such as figure 1 As shown, the exposure equipment includes an exposure base 10, a flexible film 20, an air blowing device 30 and an exposure device. Wherein the upper top surface of the exposure base 10 is a curved surface; the flexible film 20 is arranged on the upper top surface of the exposure base 10; The exposure device includes a moving assembly, an exposure lamp 40 fixedly arranged below the moving assembly, and a suction pen assembly 50 movable up and down on the moving assembly. The moving component can move relative to the exposure base 10 and is always located above the expos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com