Hyperboloidal high-current spiral contact

A technology of hyperboloids and contacts, which is applied in the direction of electrical components, parts of connecting devices, circuits, etc., can solve the problems of affecting the current carrying capacity of contacts, the scrapping rate of contacts, affecting the contact performance of products, and low reliability. Improved current carrying capacity and reliability, simple structure, and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following exemplary embodiments and descriptions are only used to explain the present invention, not as a limitation to the present invention, and, in the case of no conflict, the embodiments in the present invention and the features in the embodiments can be combined with each other .

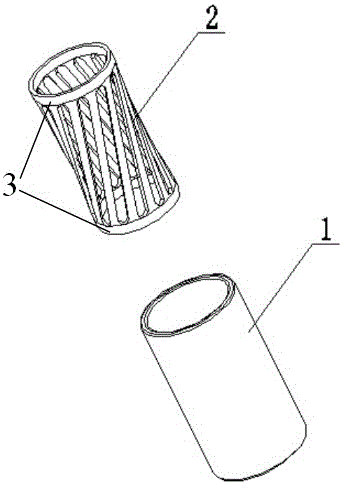

[0014] like figure 1 As shown, the embodiment of the present invention provides a hyperboloid high-current spiral contact, including a sleeve 1 and an inner sleeve connected to the inside of the sleeve 1. The inner sleeve includes connecting ends 3 at both ends and connected to the two connecting ends. 3, a plurality of shrapnels 2 are arranged in parallel in an oblique shape along the casing direction, and the shrapnels 2 are twisted along the width direction of the shrapnel 2 to form an arc, forming a hyperboloid stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com