DC motor and electric tail gate driver

A technology of DC motors and casings, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of reducing product applicability, increasing product difficulty, increasing the overall size and weight of electrodes, and achieving product applicability Effects of lifting, lightening, reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

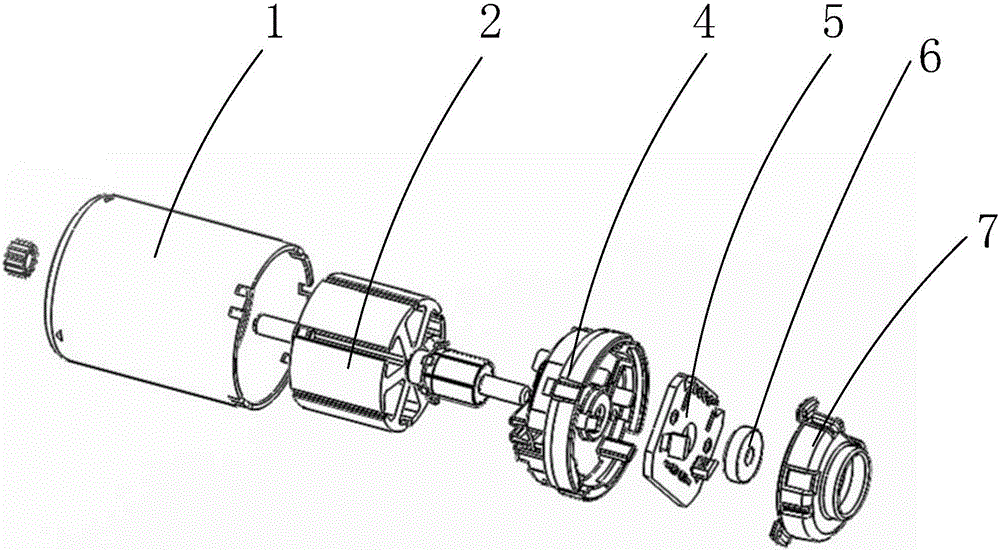

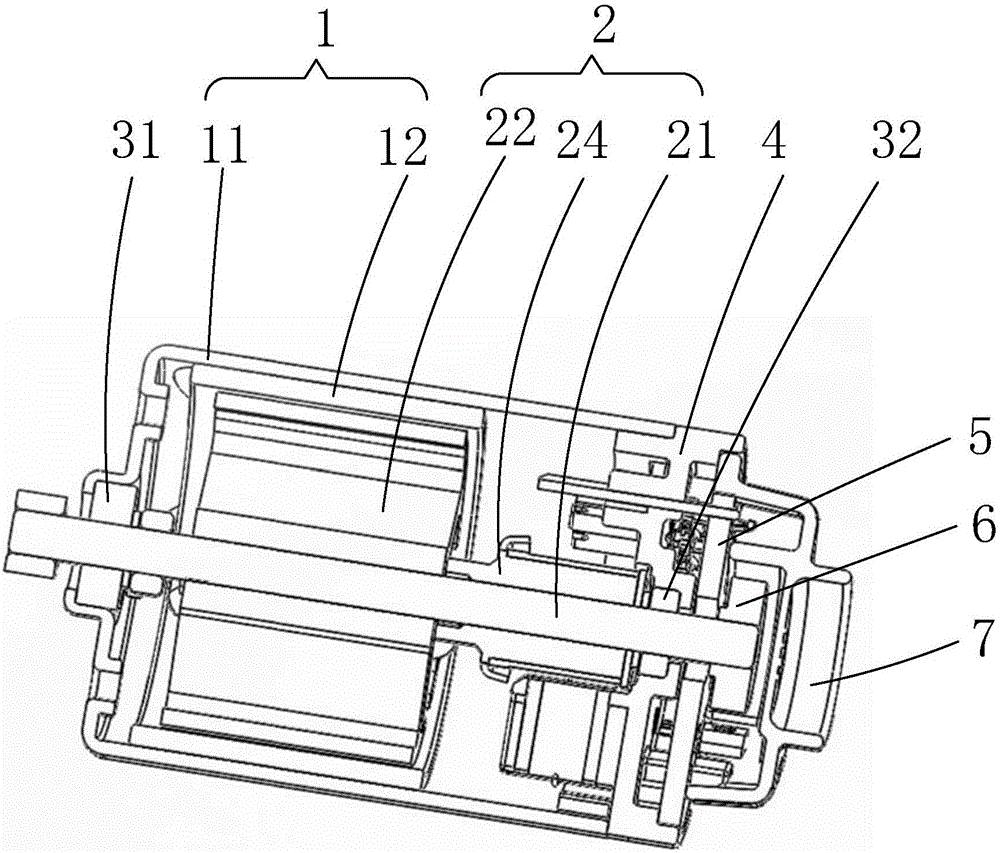

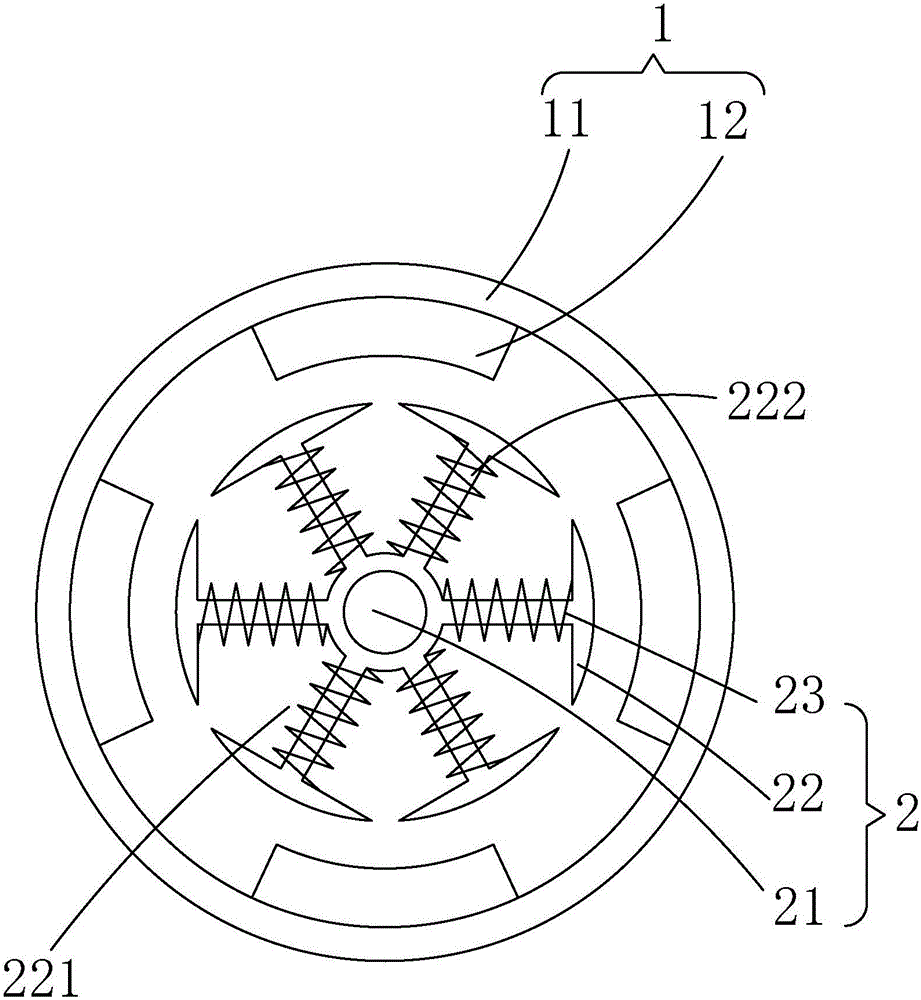

[0036] see figure 1 and figure 2 , the present invention provides a DC motor, comprising: a stator 1, and a rotor 2 accommodated inside the stator;

[0037] The DC motor meets the following conditions:

[0038] 0.9(K1+K2)≤K3≤1.1(K1+K2);

[0039] Among them, K1=D1 / D2, D1 is the outer diameter of the rotor 2, and D2 is the outer diameter of the stator 1;

[0040] K2=(Ns+Nr-1 / P) / (Ns+Nr+1 / P), Ns is the number of poles of the stator 1, Nr is the number of poles of the rotor 2, and P is the number of pole pairs of the DC motor;

[0041] K3=D2 / L, L is the effective length of the rotor.

[0042] see figure 2 and combine image 3 , in the first embodiment of the present invention, the stator 1 includes a casing 11 and a stator magnet 12 dispos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com