Primary feedback flyback LED constant current driver based on power tube drain detection technology

A technology of constant current driver and detection technology, which is applied in the direction of light sources, electrical components, lighting devices, etc., and can solve problems such as large temperature fluctuations, gradual attenuation of conversion efficiency, and increase in the number of peripheral devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

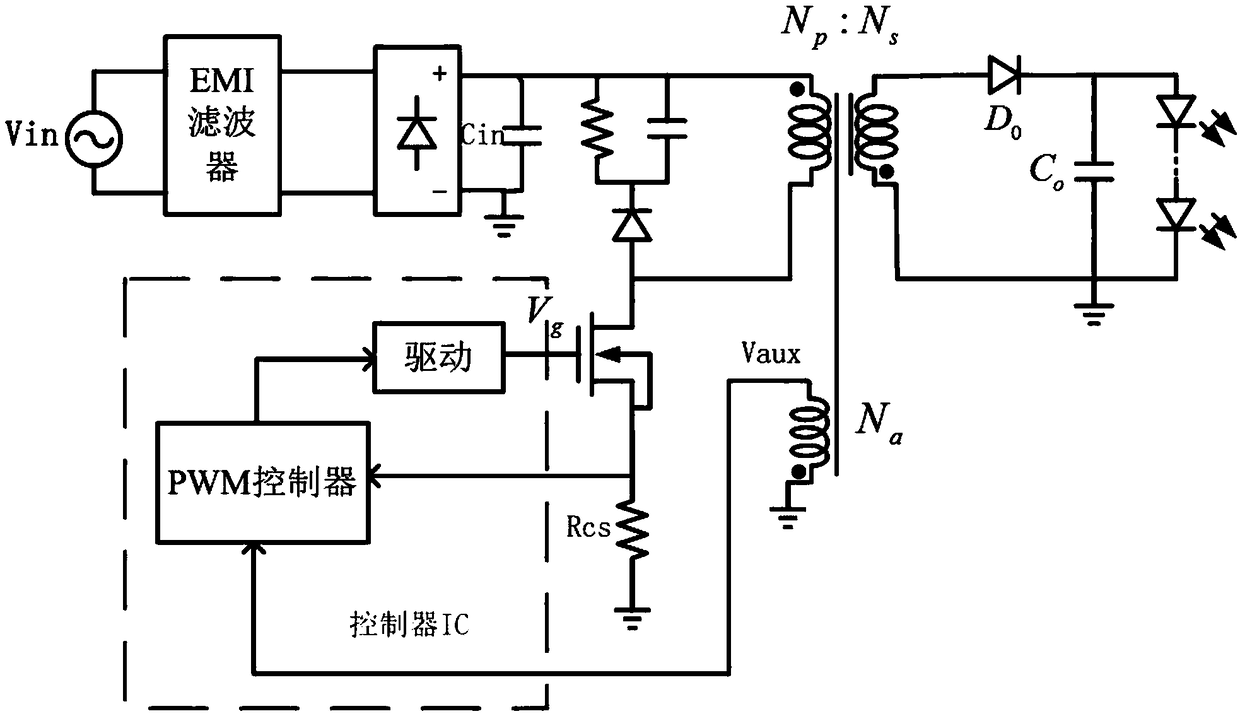

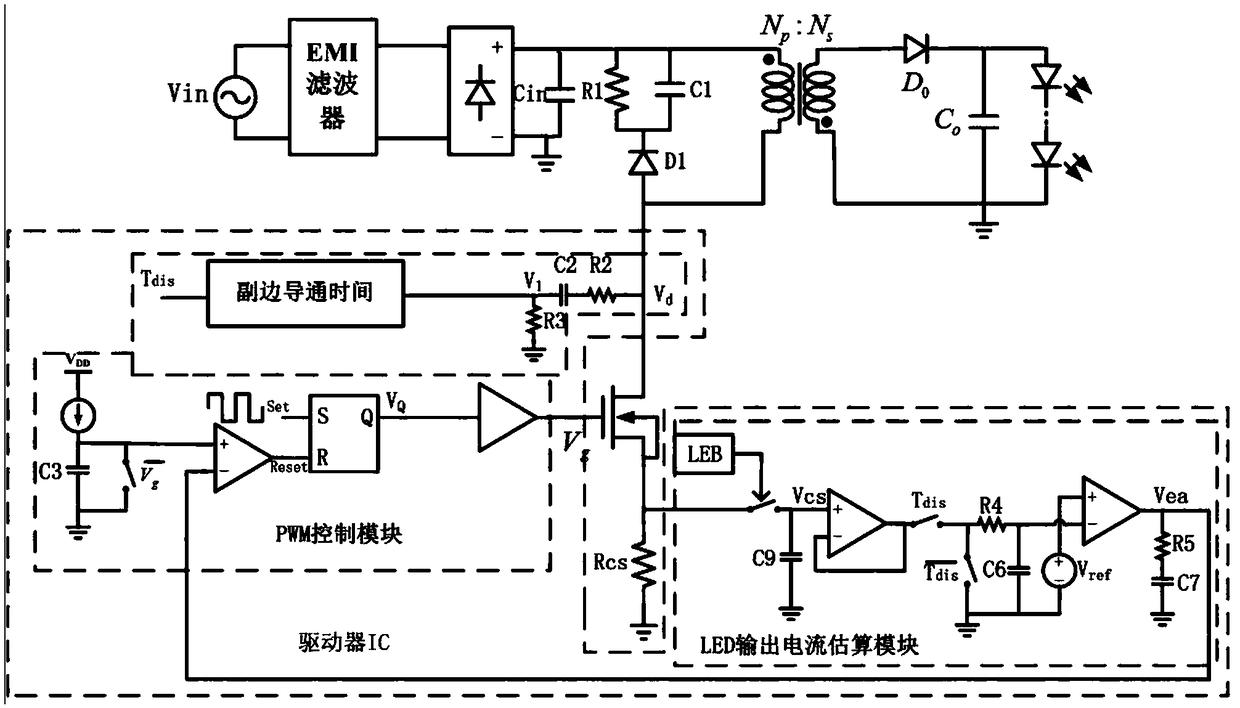

[0023] Such as figure 1 Shown: the present invention is made up of EMI filter, rectifier, three capacitors, two resistors, transformer, thyristor, diode, light-emitting diode, drive and PWM controller.

[0024] The drive includes a secondary conduction time module and an LED output current estimation module. The LED output current estimation module is composed of LEB, a dual operational amplifier chip, three capacitors, two resistors and three switches.

[0025] The secondary conduction time module is composed of a capacitor, two resistors, a switch, an operational amplifier chip and a time relay.

[0026] The LEB is composed of four operational amplifier chips and a capacitor.

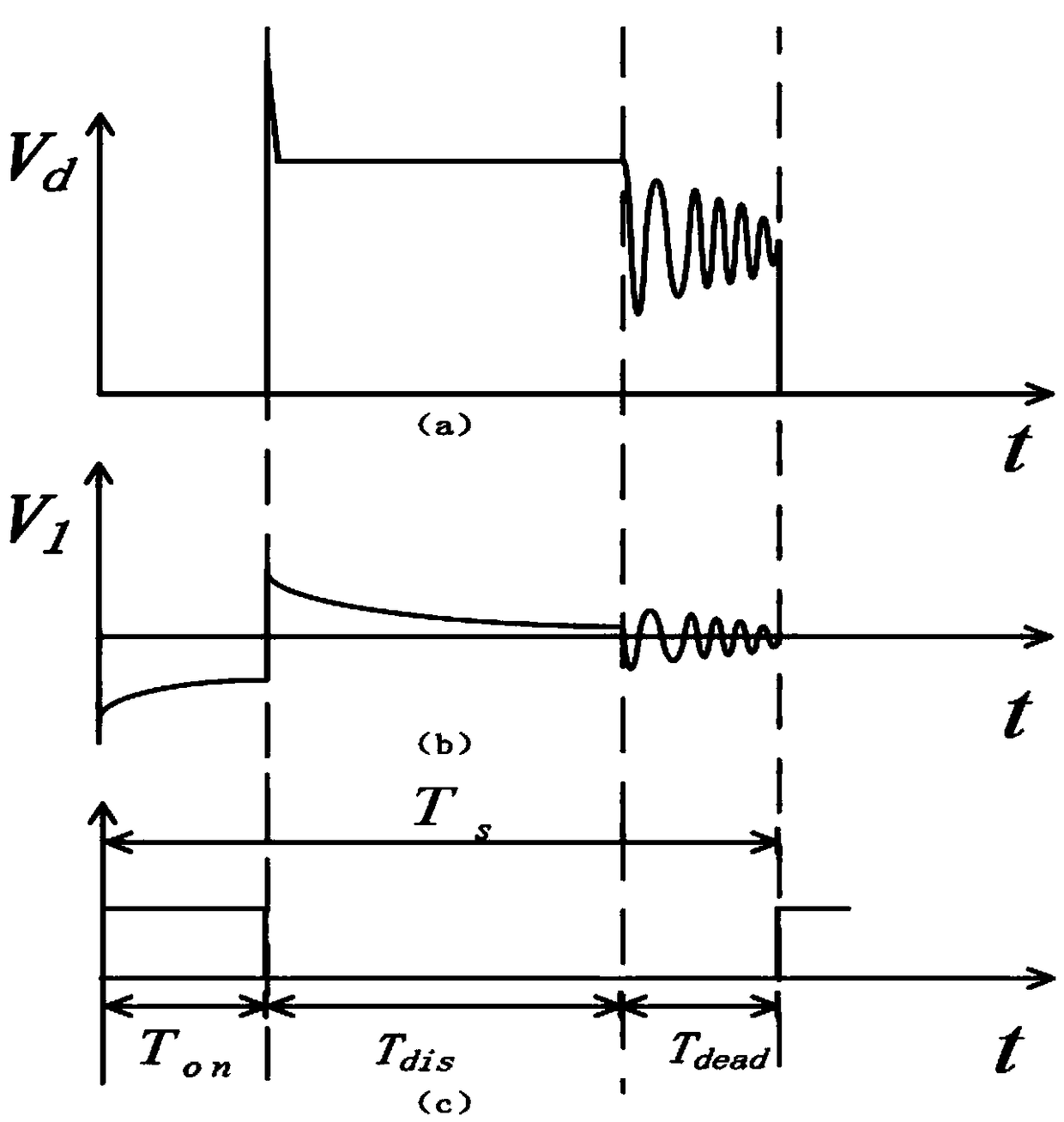

[0027] The primary side feedback flyback LED constant current driver system based on power tube drain detection technology is as follows: figure 2 As shown, the system mainly includes EMI filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com