Mortar spreader for laying floor tiles

A technology for laying ash and floor tiles, which is applied in construction, building structure, etc., can solve the problems of low efficiency of scraping method, inability to guarantee construction quality, etc., and achieve the effects of fast construction speed, good adhesion and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

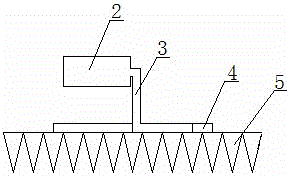

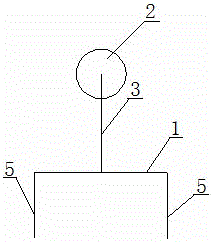

[0013] see Figure 1 to Figure 2 , a dust spreader for floor tile laying, comprising a thick iron plate 1, the upper part of the thick iron plate 1 is vertically provided with a connecting rod 3; the top of the connecting rod 3 is provided with a handle 2, and the thick iron plate The two sides of 1 are provided with vertically downward sawtooth 5.

[0014] see Figure 1 to Figure 2 , the serrations 5 on both sides of the thick iron plate 1 are in the same direction as the handle 2; that is, the handle 2 and the serrations 5 are parallel in space.

[0015] see Figure 1 to Figure 2 , the connecting rod 3 is made of round steel I, and the connecting rod 3 is set on the thick iron plate 1 through the round steel II4.

[0016] see Figure 1 to Figure 2 , when in use, lay the mortar first, grasp the handle 2 with your hand, insert th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com