New composite high-speed exhaust intake valve

A compound type, intake valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of water leakage, increase of valve height, inability to use pipelines, etc., to achieve earlier rise time, slow rise speed, and reduce water volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

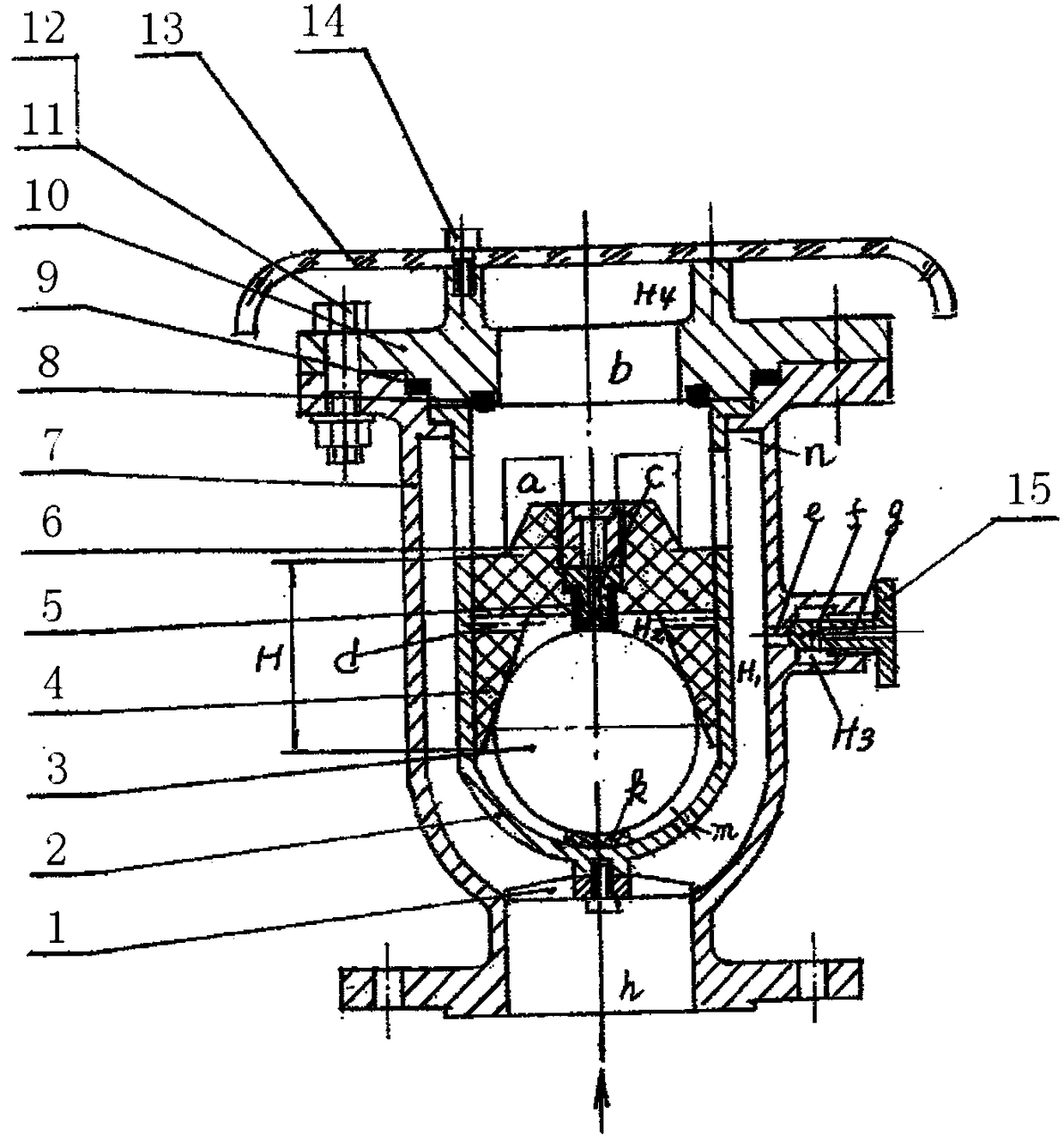

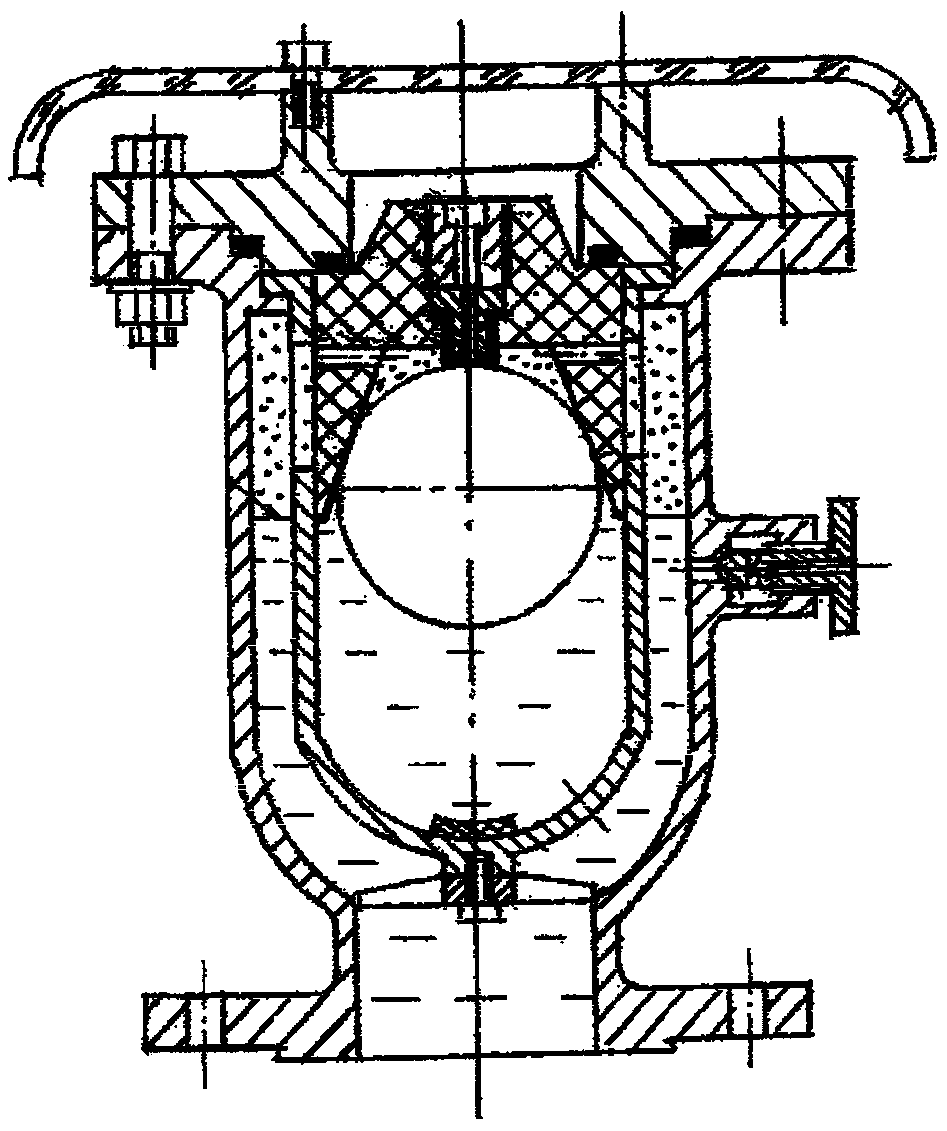

[0024] like figure 1 As shown, the present invention consists of deflector 1, floating ball cover 2, floating ball 3, lifting cover 4, exhaust nozzle 5, set screw 6, valve body 7, O-ring one 8, O-ring two 9. It consists of valve cover 10, bolt 11, nut 12, exhaust cover 13, screw 14 and detection screw 15.

[0025] The valve body 7 is a hollow valve casing with flanges at both ends and a cylinder in the middle. The lower through hole is the water inlet h, and its diameter is smaller than the inner diameter of the cylinder; Flange connection, the lower flange of the inspection valve is connected to the corresponding flange of the water pipe, and the inspection valve is closed when the exhaust valve is inspected to prevent the water in the pipe from spraying out; the outer edge of the upper flange is provided with 8-12 There are two evenly distributed mounting holes, and the valve body 7, the valve cover 10 and the floating ball cover 2 are fixed together with bolts 11, nuts 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com