High-ground-clearance-boom-sprayer water returning pipe system

A boom spraying and return water pipeline technology, which is applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problem of poor spray quality, insufficient mixing of medicinal liquids, and inability to balance medicinal liquids in medicine boxes in real time. and return water mixing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

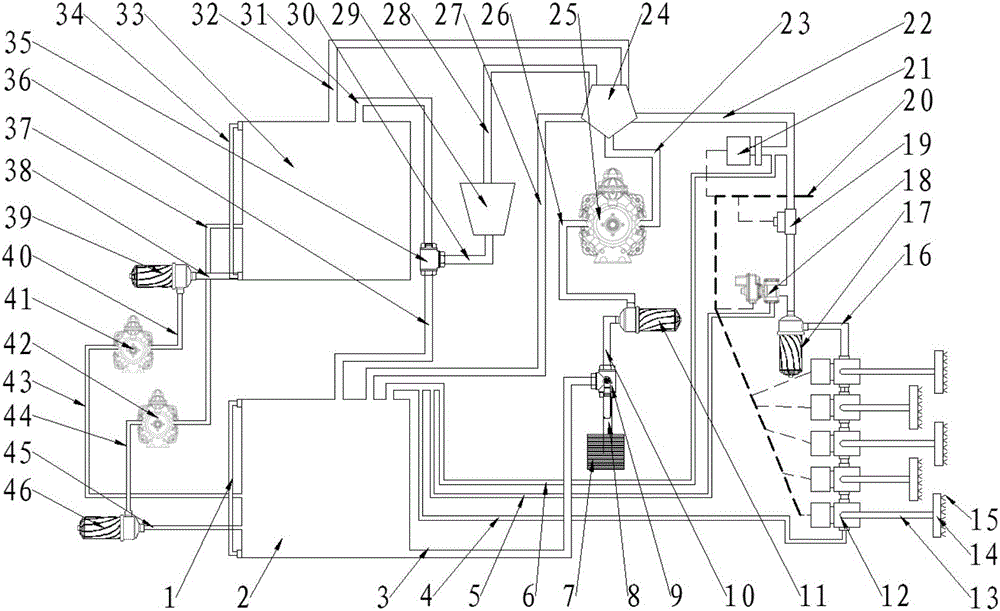

[0019] The present invention is mainly used for automatic water supply, automatic drug mixing, real-time jet agitation, and precision spraying of the split-type medicine box of the high-ground-clearance boom sprayer. The device provided by the present invention will be referred to below figure 1 The working principle of the return water pipeline system of a high ground clearance boom sprayer of the present invention is described.

[0020] Such as figure 1As shown, a return water pipeline system of a high ground clearance boom sprayer of the present invention includes a main medicine tank liquid level gauge 1, a main medicine tank 2, a liquid supply pipe 3, a spray return pipe 4, an overcurrent return pipe 5, an overpressure Water return pipe 6, water supply pipe 8, three-way valve 9, filter inlet liquid pipe 10, primary filter 11, solenoid valve group 12, drug delivery pipe 13, spray rod 14, nozzle 15, filtered output pipe 16, secondary Filter 17, flow regulating device 18, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com