Electronic cigarette heating atomization component

A technology of electronic cigarettes and components, applied in tobacco, smoker supplies, applications, etc., can solve the problems of inconvenient, dry burning, waste of smoke liquid installation, etc., and achieve the effect of not being easy to dry burning, easy to install, and solving dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] All the features disclosed in this specification, except mutually exclusive features and / or steps, can be combined in any way.

[0019] Combine below Figure 1~4 The present invention will be described in detail.

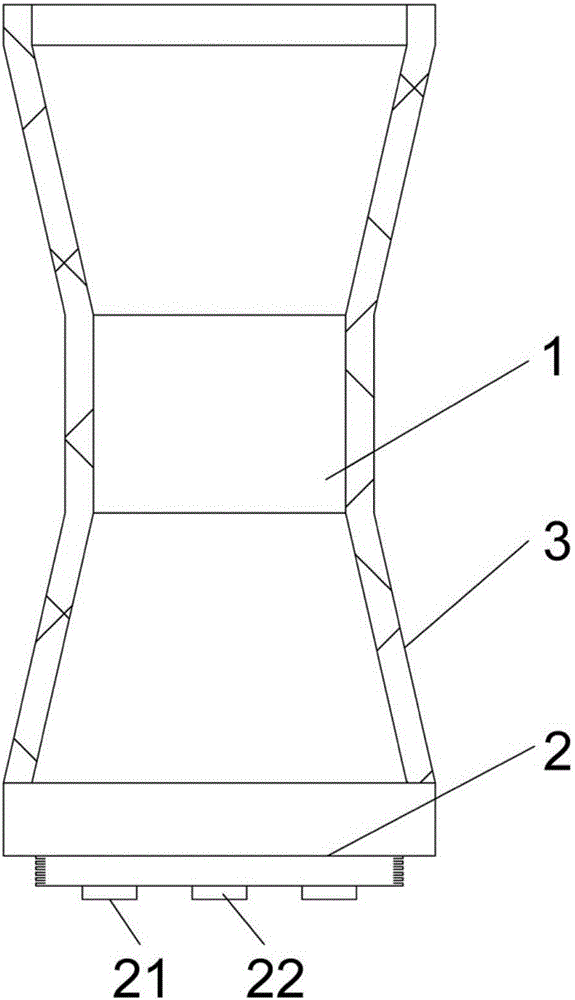

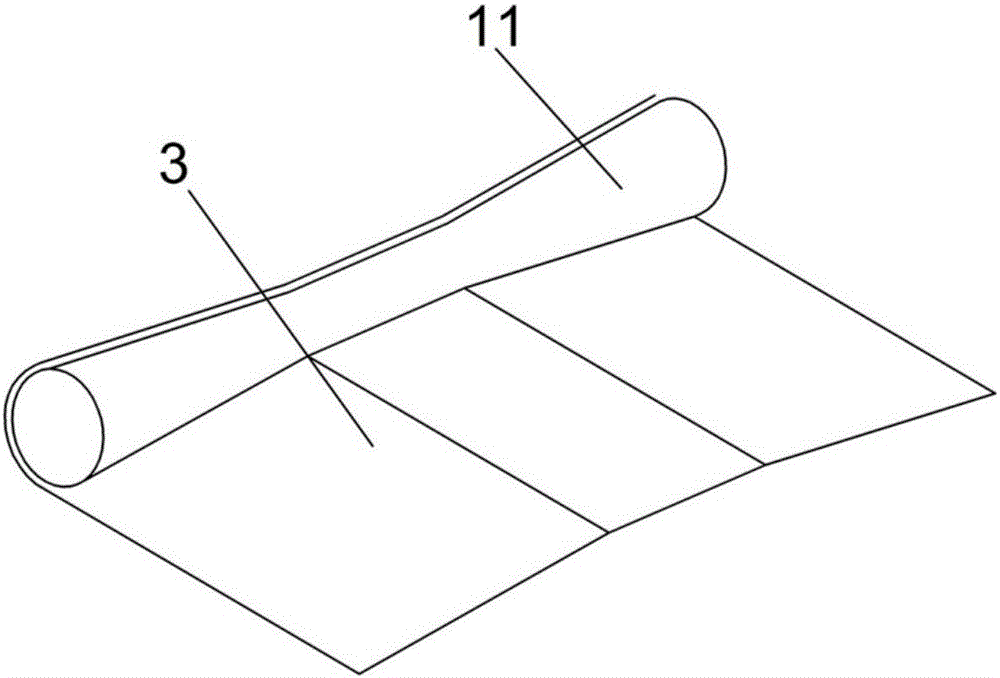

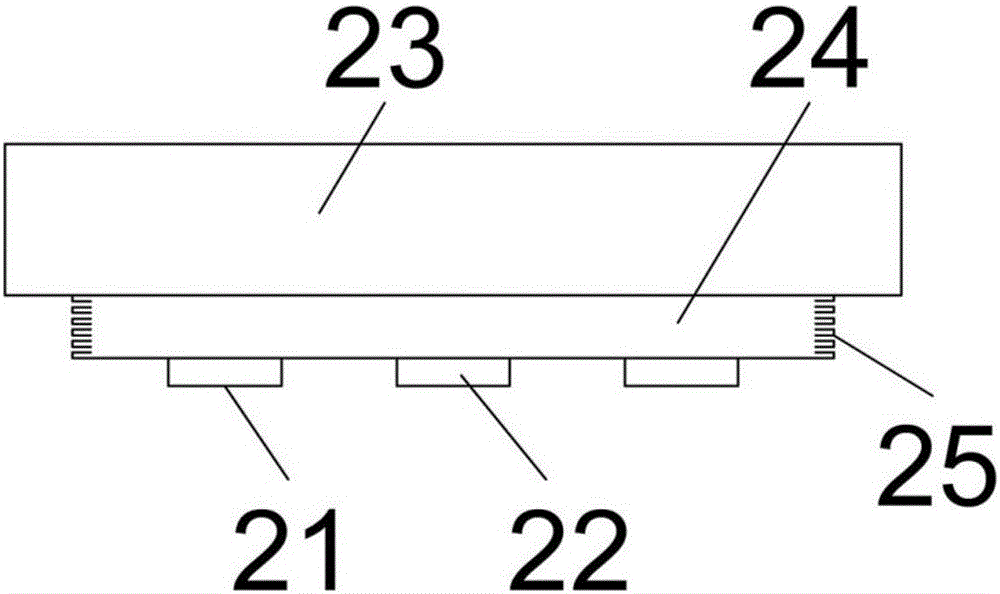

[0020] An electronic cigarette heating and atomizing element, including a heating part 1 and a connecting part 2, the connecting part 2 includes a positive connecting wire 21 and a negative connecting wire 21 of the heating element, the heating part 1 includes a heating core 11, and the heating core 11 is a ceramic heating core , such as porous ceramics, foam ceramics and other commonly used ceramics, these ceramic materials have high chemical stability, high thermal conductivity and high rate of gas molecules can pass through, and do not chemically react with smoke liquid; the heating core consists of funnel-shaped ends 111 and a connecting funnel The middle straight section 112 at both ends is formed, and the interior of the funnel-shaped two ends 111 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com