Dust removal system for waste and old product recovery line

A product recovery and dust removal system technology, applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve problems affecting ambient air quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

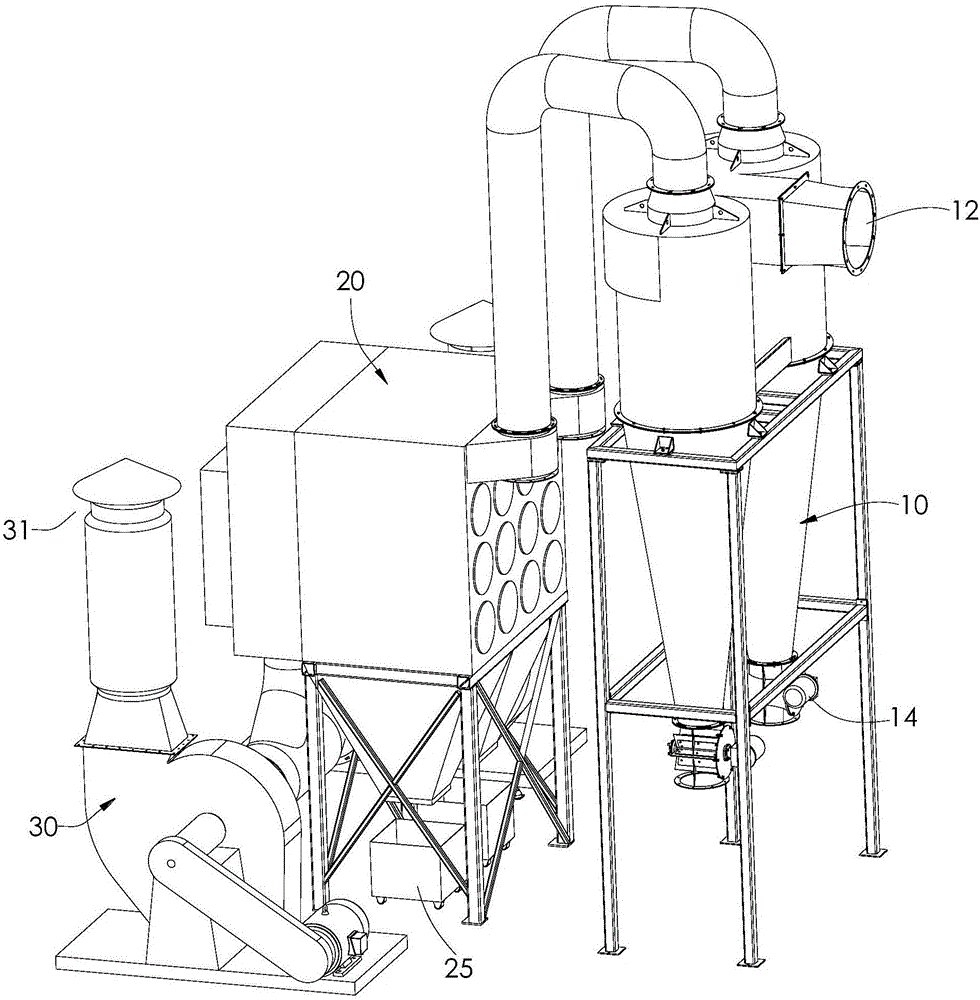

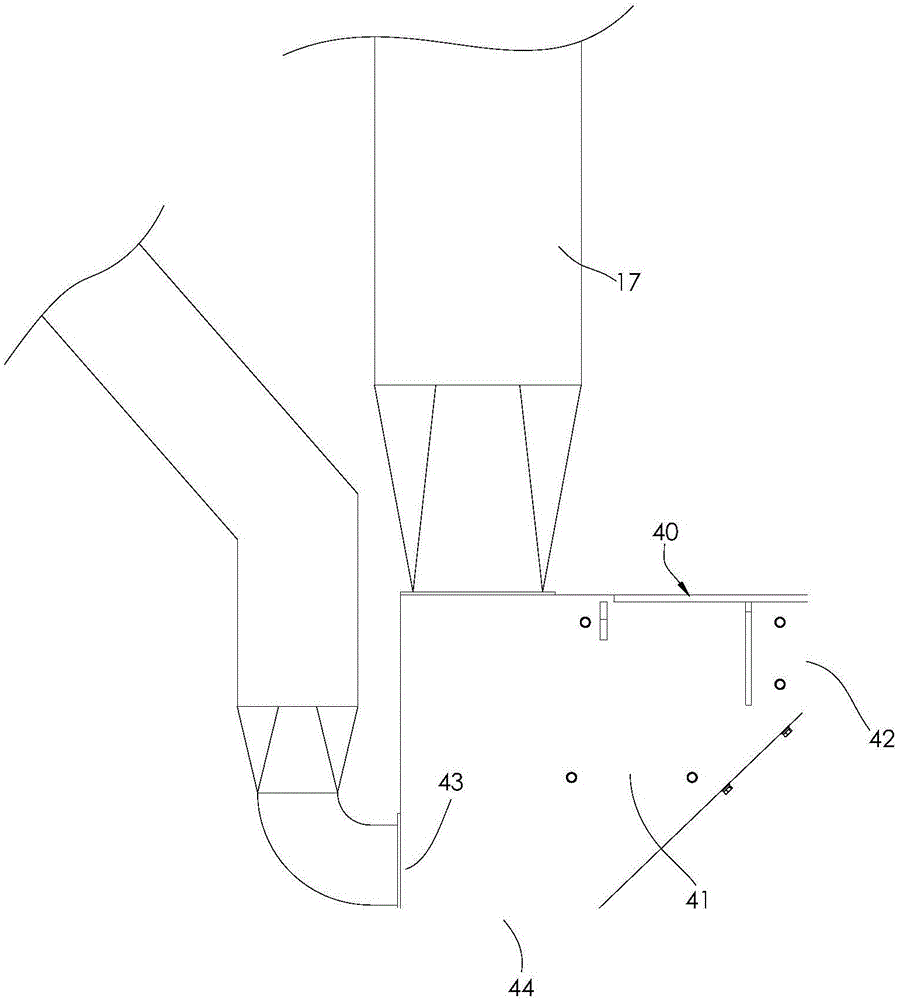

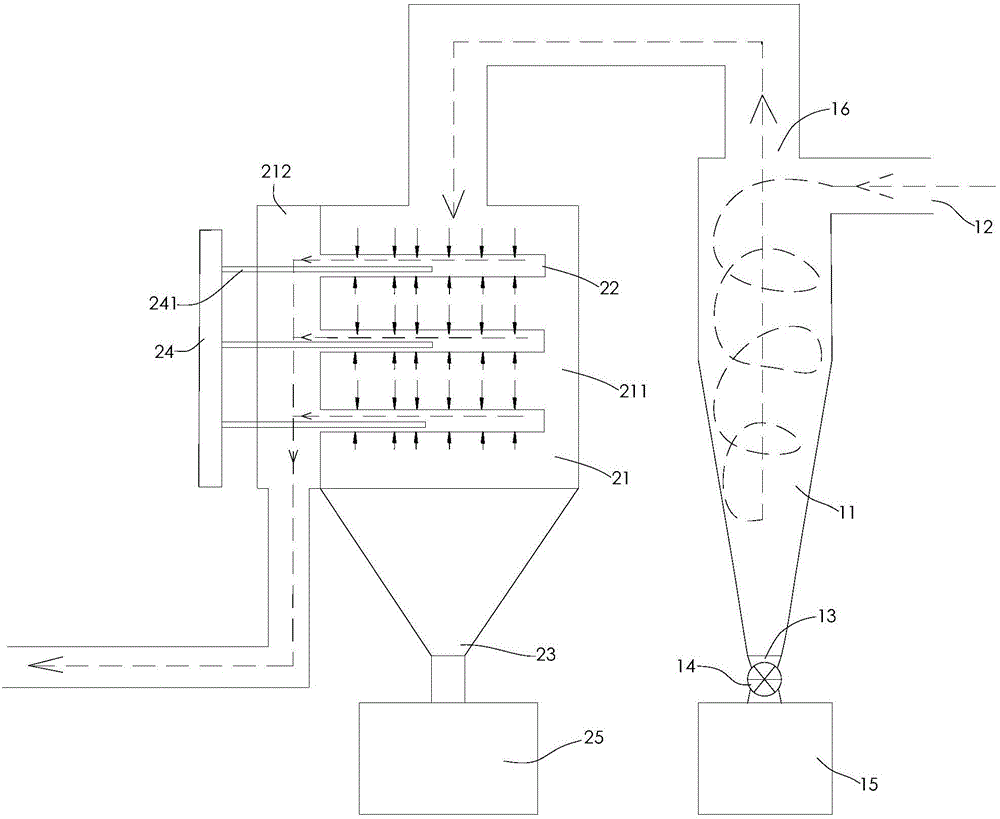

[0024] Such as Figures 1 to 3 As shown, the dust removal system of the waste product recovery line of the present invention includes a cyclone dust collector 10 , a pulse dust collector 20 and a fan 30 . The cyclone dust collector 10 includes an air inlet and an air outlet, and the air inlet is used for the air discharged from the machine to enter; the pulse dust collector 20 includes a housing, an air supply device 24 and several filter elements 22; the inside of the housing has a filter chamber 21, The filter cavity 21 includes a first cavity 211 and a second cavity 212 isolated from each other, and several filter elements 22 are arranged in the first cavity 211; each filter element 22 has an inner space, and the inner space is connected to the filter element The filter hole of 22 communicates, and this internal space communicates with the second ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com