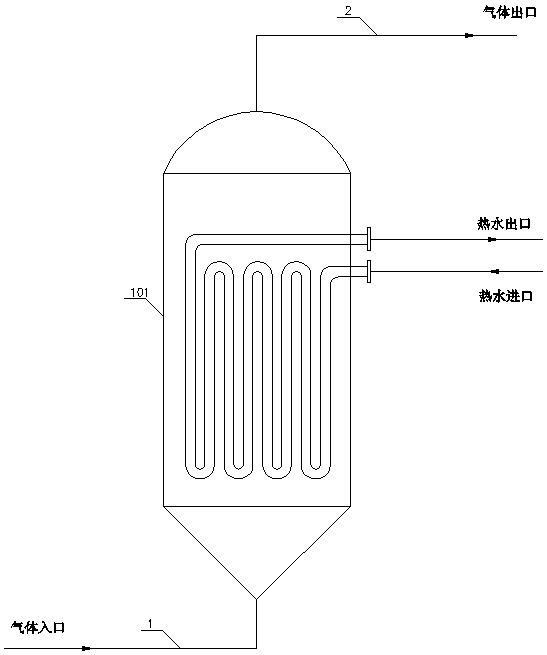

A forced cooling process and device for regeneration process

A technology of forced cooling and regeneration process, which is applied in the direction of chemical/physical process, catalyst regeneration/reactivation, physical/chemical process catalyst, etc. It can solve the problems of long regeneration time and achieve fast regeneration speed, low cost and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0041] Embodiment 2, this embodiment is compared with embodiment 1, the technological process and the used device are the same, the difference is: the technological parameters are different, and the specific steps are as follows:

[0042] 1) The beginning of regeneration;

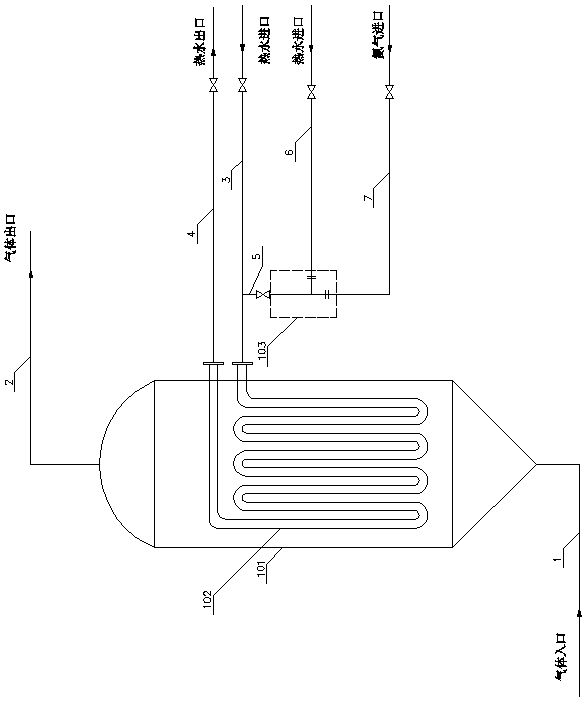

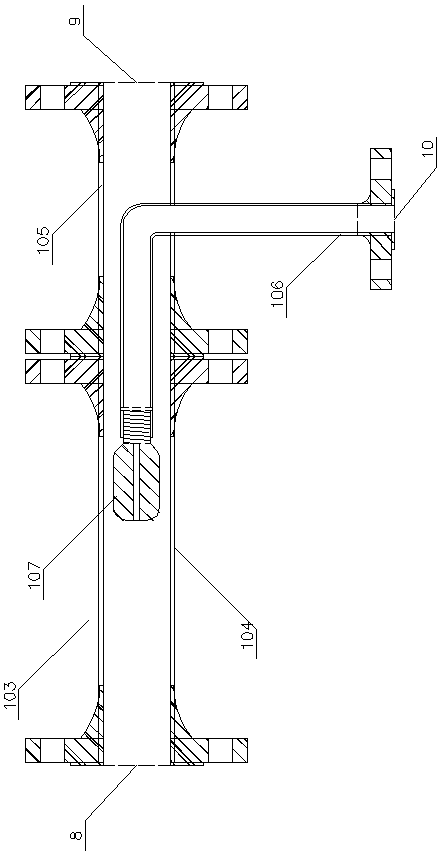

[0043] Open the first pipeline 1 and the second pipeline 2, open the regeneration circuit, and set the pressure to 0-3000Nm 3 The flow rate of / h is passed into the air for regeneration, the temperature of the fluidized bed 101 is raised from 180 ° C to 400 to 430 ° C, and at the same time, the third pipeline 3 and the fourth pipeline 4 are opened, so that the production loop is open and vacant;

[0044] 2) Regeneration constant temperature stage;

[0045] ①The temperature of the fluidized bed 101 rises to 400~430℃ and enters the regeneration constant temperature stage, closes the third pipeline 3, opens the fifth pipeline 5, the seventh pipeline 7, and the sixth pipeline 6, and opens the forced cooling ci...

Embodiment 3

[0053] Embodiment 3, this embodiment is compared with embodiment 1, the technological process and the used device are the same, the difference is: the technological parameters are different, and the specific steps are as follows:

[0054] 1) The beginning of regeneration;

[0055] Open the first pipeline 1 and the second pipeline 2, open the regeneration circuit, and set the pressure to 0-3000Nm 3 The flow rate of / h is passed into the air for regeneration, the temperature of the fluidized bed 101 is raised from 180 ° C to 400 to 430 ° C, and at the same time, the third pipeline 3 and the fourth pipeline 4 are opened, so that the production loop is open and vacant;

[0056] 2) Regeneration constant temperature stage;

[0057] ①The temperature of the fluidized bed 101 rises to 400~430℃ and enters the regeneration constant temperature stage, closes the third pipeline 3, opens the fifth pipeline 5, the seventh pipeline 7, and the sixth pipeline 6, and opens the forced cooling ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com