Jetting mechanism

A spray mechanism and piston technology, applied to spray devices, single handheld devices, etc., can solve problems such as inconvenient operation of spray guns, increase in valve body volume, and increase in weight of spray guns, and achieve large spray dose, long range, and effective surface. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

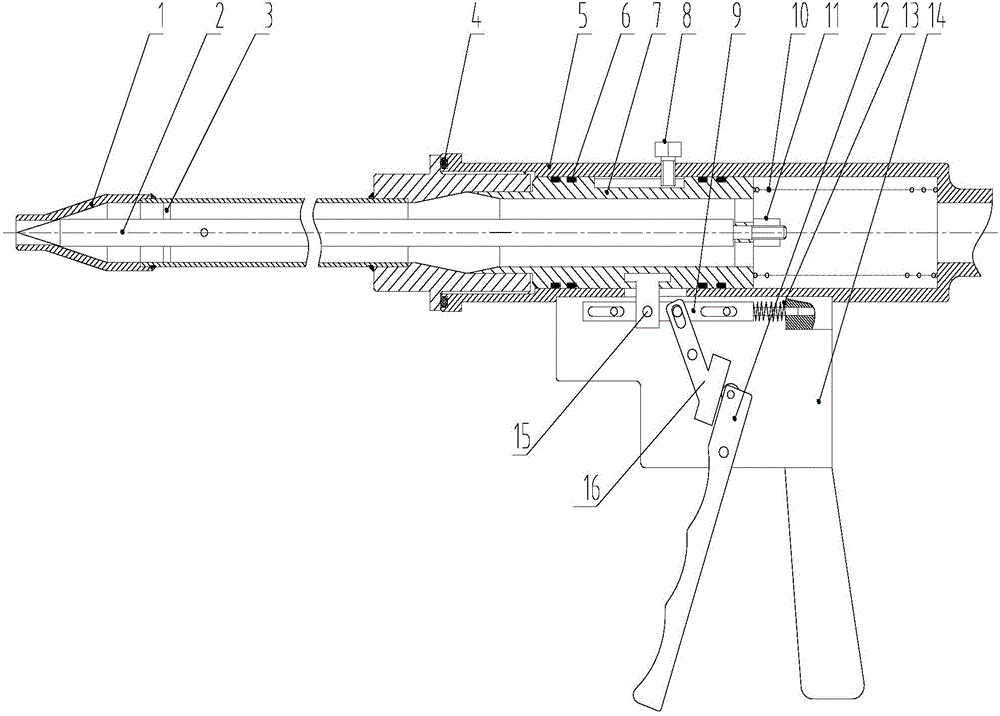

[0018] The invention provides a spraying mechanism, see attached figure 1 , including: gun barrel welding 1, valve stem 2, guide rod 3, first sealing ring 4, valve seat 5, second sealing ring 6, piston 7, guide pin 8, first connecting rod 9, return spring 10, Nut 11, trigger 12, connecting rod return spring 13, box body 14, pushing block 15 and second connecting rod 16;

[0019] The gun barrel welding 1 is composed of a conical barrel section and a small cylindrical section and a large cylindrical section respectively docked with the two ends of the conical cylindrical section; pad;

[0020] One end of the valve stem 2 is a conical structure;

[0021] The outer circumferential surface of the piston 7 is processed with strip grooves;

[0022] The outer peripheral surface of the valve seat 5 is processed with a strip-shaped through hole;

[0023] The ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com