Architecture sectional material cleaning device

A technology for cleaning devices and profiles, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problems of poor stability of building profiles, high labor intensity, and small scope of application, etc. Achieve the effect of improving recycling efficiency, reducing water consumption and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

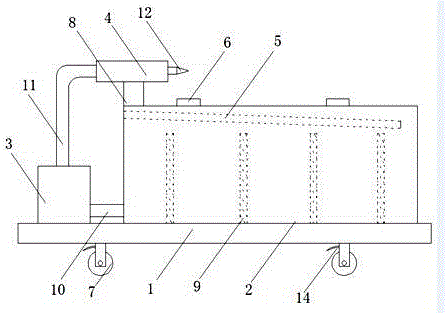

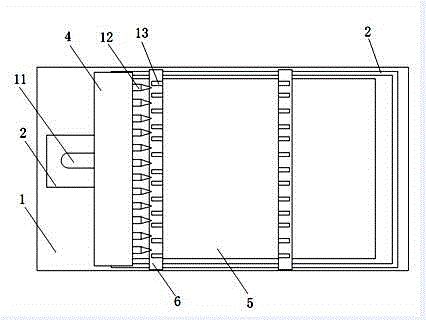

[0017] as attached Figure 1-2 As shown, a building profile cleaning device includes a bottom plate 1, a water pool 2, a water pump 3, a shunt pipe 4, a guide plate 5, a carrying plate 6 and a roller 7, and is characterized in that: the water pool 2 is arranged on the bottom plate 1. , a fixed block 8 is arranged on the pool 2, and a sieve plate 9 is arranged in the pool 2. The number of the sieve plate 9 is set to 4 layers, and the mesh number of the sieve plate 9 is set from one end close to the water pump 3. Decrease from near to far, the water pump 3 is arranged on the bottom plate 1, the water pump 3 is connected to the pool 2 through the water delivery pipe 10, and a drain pipe 11 is arranged on the water pump 3, and the shunt pipe 4 is arranged in a fixed position. On block 8, the shunt pipe 4 is connected with the drain pipe 11, and the nozzle 12 is arranged on the shunt pipe 4, the guide plate 5 is arranged in the pool 2, and the guide plate 5 is arranged in the pool ...

Embodiment 2

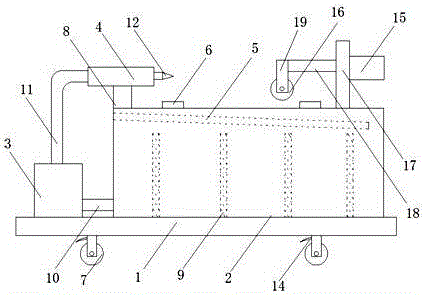

[0024] as attached Figure 3-4 As shown, a building profile cleaning device includes a bottom plate 1, a pool 2, a water pump 3, a shunt 4, a deflector 5, a carrier plate 6, a roller 7, a cylinder 15 and a brush 16, characterized in that: the The pool 2 is arranged on the bottom plate 1, a fixing block 8 and a positioning plate 17 are arranged on the pool 2, and a sieve plate 9 is arranged in the pool 2, and the number of the sieve plates 9 is set to 4 layers, and the sieve The mesh number of the plate 9 decreases from near to far from the end close to the water pump 3. The water pump 3 is arranged on the bottom plate 1, the water pump 3 is connected to the pool 2 through the water delivery pipe 10, and a drain pipe is arranged on the water pump 3. 11. The shunt pipe 4 is arranged on the fixing block 8, the shunt pipe 4 is connected with the drain pipe 11, and the nozzle 12 is arranged on the shunt pipe 4, and the guide plate 5 is arranged in the pool 2, and The guide plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com