Submerged arc welding consumables for duplex stainless steel

A technology of duplex stainless steel and submerged arc welding, which is applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems of difficult processing of solid welding wire, achieve low processing difficulty, simplify the baking process, and not easily The effect of moisture absorption

Active Publication Date: 2019-01-22

HAINING RUIAO METAL TECH CO LTD

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In view of the deficiencies in the prior art, the object of the present invention is to provide a flux-cored welding wire and flux for submerged arc welding of duplex stainless steel, so as to solve the problem of difficult processing caused by solid-core welding wire and improve the welding process performance at the same time. Improve welding efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-8

[0041]See Table 3 for the welding wire and flux combinations and welding process performance results used in the eight embodiments. The results show that the welding slag detachability, weld bead shape and welding quality all meet the requirements.

[0042] The welding speed of the embodiment is 40-45cm / min, which is higher than that of solid wire (below 35cm / min), and the efficiency can be increased by about 15%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

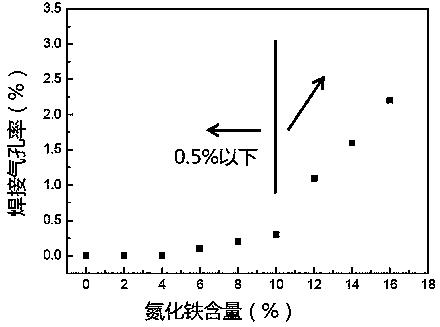

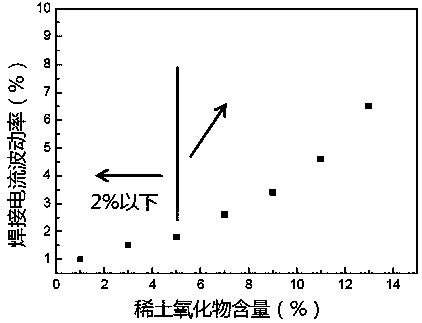

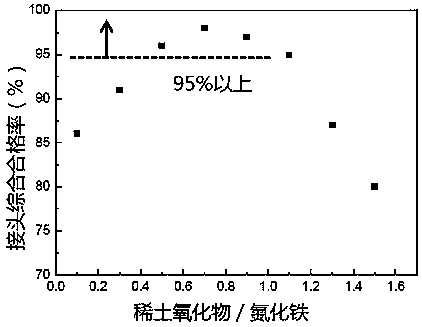

The invention discloses a submerged arc flux-cored wire welding flux for duplex stainless steel. A flux-cored wire comprises a wrapper and core powder; the wrapper contains the following components in percent by weight: smaller than or equal to 0.04% of C, 0.1-1.0% of Si, 1.0-2.0% of Mn and 5-15% of Cr; the core powder comprises 30-45% of Cr, 20-35% of Ni, 10-25% of Mo, 1-10% of iron nitride and 1-5% of rare earth oxide; the core powder filling rate is 18-30%; the ratio of the rare earth oxide to the nitride is 0.5-0.9; the welding flux comprises the following components: 8-16% of CaF2, 10-18% of Al2O3, 10-16% of SiO2, 5-15% of BaO, 5-15% of SrCO3 and a proper amount of a bonding agent.

Description

technical field [0001] The invention relates to a submerged arc welding material for stainless steel, in particular to a submerged arc flux-cored welding wire and flux for duplex stainless steel. Background technique [0002] Due to its excellent corrosion resistance and high strength, duplex stainless steel has been widely used in chemical containers, oil wells, LNG ships, seawater desalination equipment, vehicle manufacturing and other fields, among which 2205 (UNS S32205) is the most widely used. The pitting corrosion resistance of duplex stainless steel is better than that of traditional austenitic stainless steel 304L and 316L. [0003] Manual arc welding, gas shielded arc welding, and submerged arc welding are the most commonly used welding methods for duplex stainless steels. The prior art JP4672177 provides a combination of solid wire and flux for submerged arc welding, which is less difficult to process and less likely to cause welding defects; the solid wire is de...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K35/365B23K35/362B23K35/368

CPCB23K35/362B23K35/365B23K35/368

Inventor 张盘

Owner HAINING RUIAO METAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com