Assembly method and device for self-locking nuts between aero-engine air compressor rotor discs

A technology for compressor rotors and aero-engines, which is used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of delayed delivery of compressor rotors, decreased personnel concentration, bumped ratchet wrenches, etc., and shortens the assembly time. , avoid bumps, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

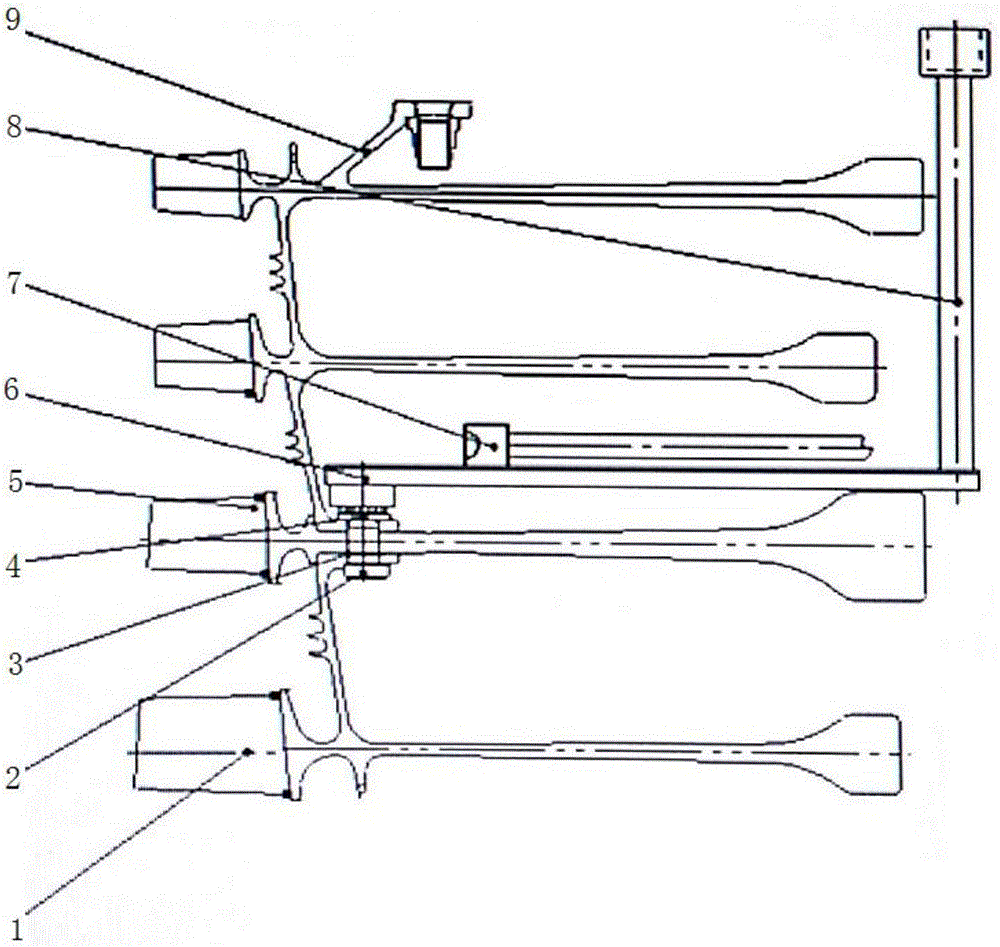

[0024] refer to figure 1 , an assembly device for self-locking nuts between rotor discs of an aero-engine compressor, comprising a pulley drive wrench 6 and a wrench adapter section 8, the pulley drive wrench 6 is placed along the center direction of the fourth-stage disc, and is installed on the fourth-stage The self-locking nut 4 on the disk is located in the pulley drive wrench 6 to ensure that the end of the self-lock nut 4 is close to the inner wall of the pulley drive wrench, and the wrench adapter section 8 is vertically connected with the pulley drive wrench 6 . An observation device is included, the observation device is fixed at a third of the distance from the pulley drive wrench 6 to the self-locking nut, and the probe 7 of the observation device faces the head of the wrench for observation. Butter is smeared on the self-locking nut. The pulley drive wrench 6 is provided with a square hole for connecting the wrench adapter section 8 .

[0025] A method for assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com