Nine-station machine tool for surface milling and drilling of taper sleeves and process of nine-station machine tool

A technology of milling surface and taper sleeve is applied in the field of taper sleeve processing, which can solve the problems that the taper sleeve cannot be matched with the pulley, reduce the production output, and can not meet the requirements, so as to reduce the labor intensity of workers, increase the production output, and improve the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

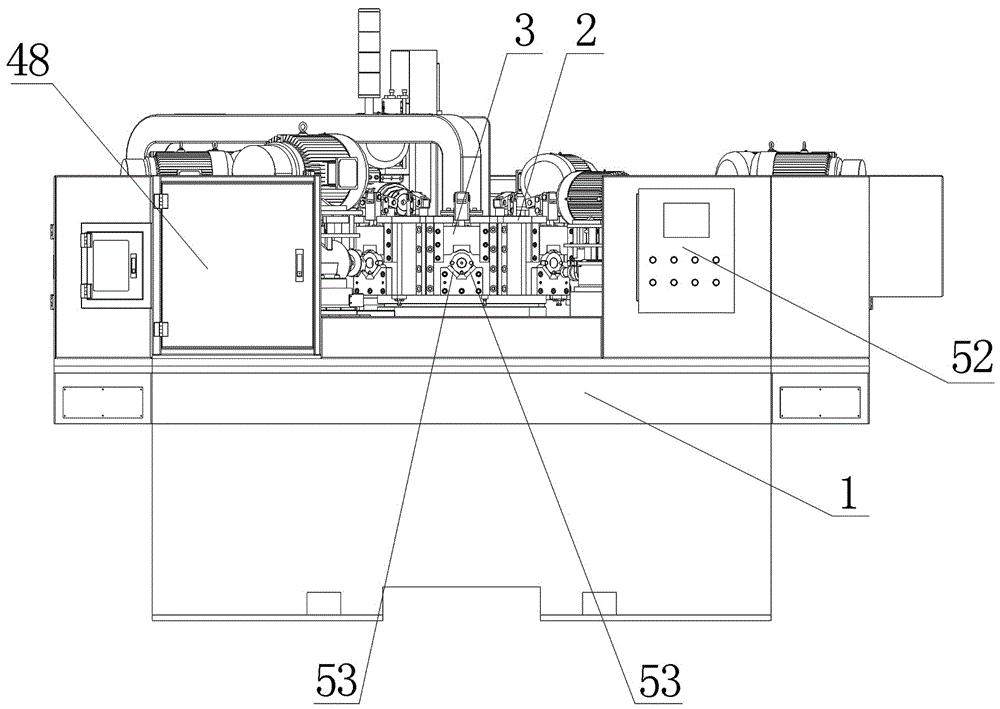

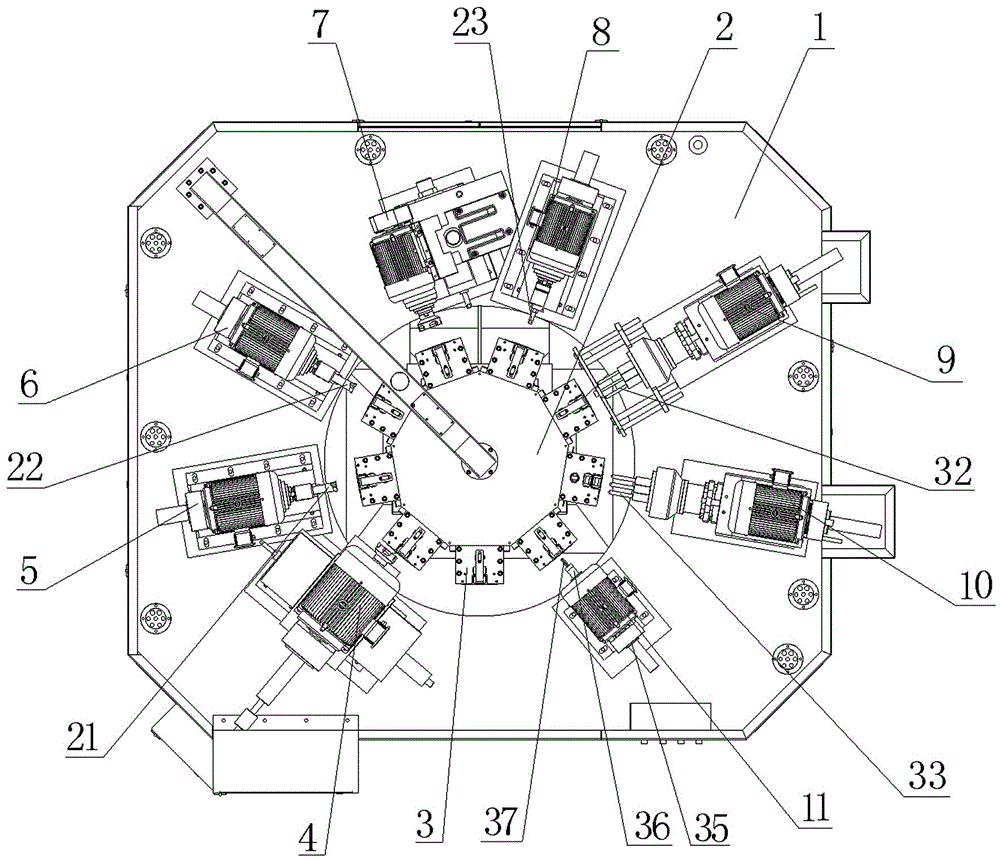

[0039] Such as figure 2 and image 3 As shown, a nine-station machine tool for taper sleeve milling and drilling, it includes a body 1 and a hydraulic gear splitting table 2 that is rotatably mounted on the top of the body 1, and the outer surface of the hydraulic gear splitting table 2 is Nine blank tooling fixtures 3 are evenly arranged on the edge, and on the top of the machine body 1, with the oil pressure gear type dividing table 2 as the center of the circle, there are sequentially arranged a surface rough milling unit 4, a rough boring unit 5, a half Fine boring processing unit 6, face fine milling processing unit 7, fine boring processing unit 8, drilling unit 9, chamfering unit 10 and tapping unit 11;

[0040] Such as Figure 2~4 As shown, the surface rough milling unit 4 includes a cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com