Bamboo hat magazine cutter feeding performance detecting method and device

A detection device and tool magazine technology, applied in positioning devices, measuring/indicating equipment, clamping, etc., can solve the problems of cumbersome, difficult detection, and complex design of cylindrical groove cam curves, etc., to achieve stable operation, ensure reliability, The effect of ensuring the accuracy of the data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing:

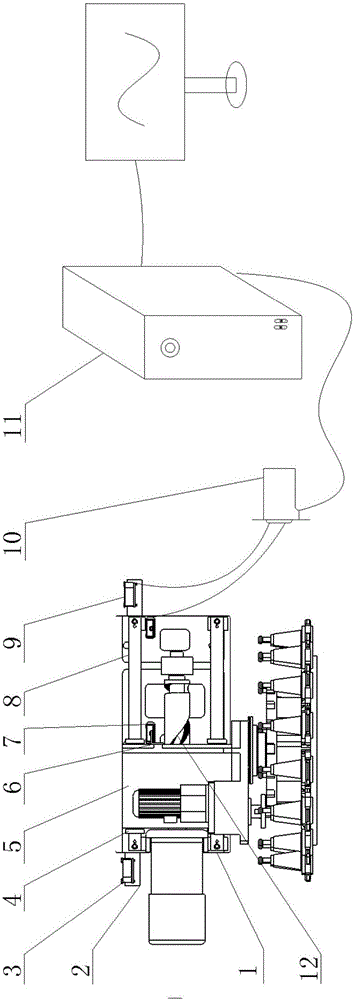

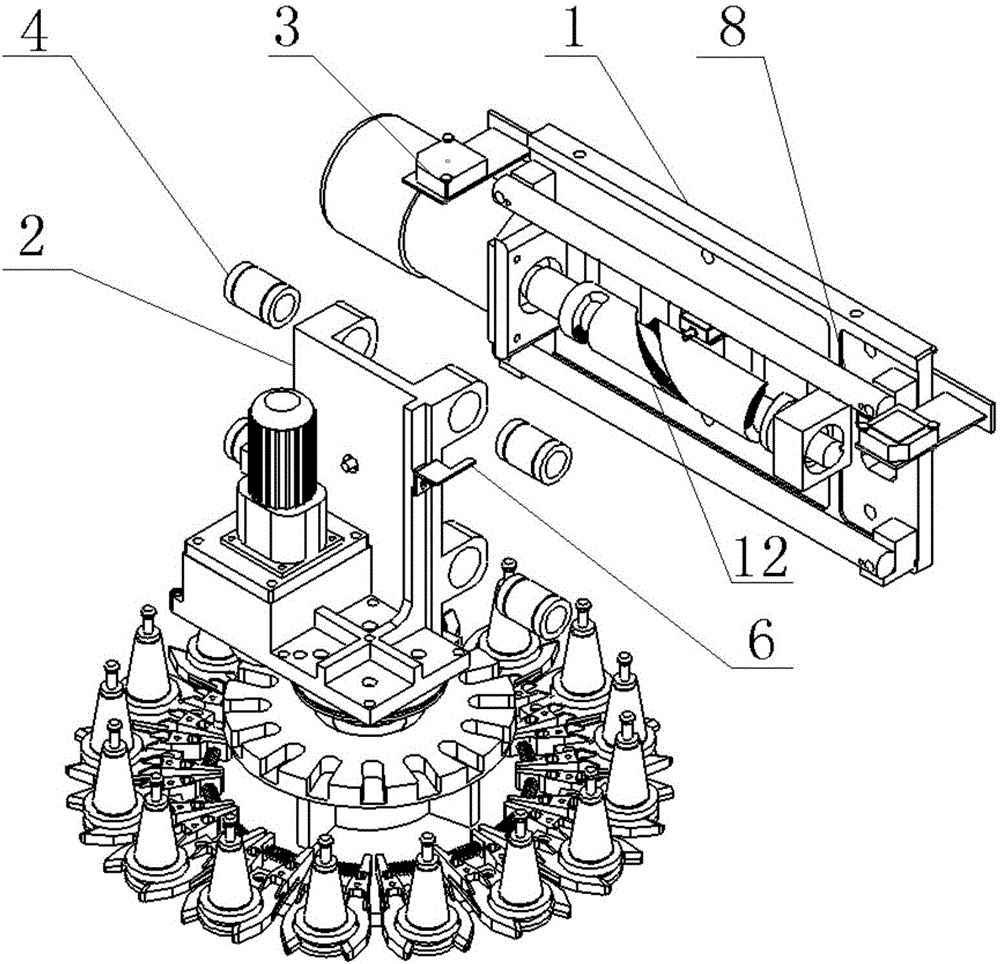

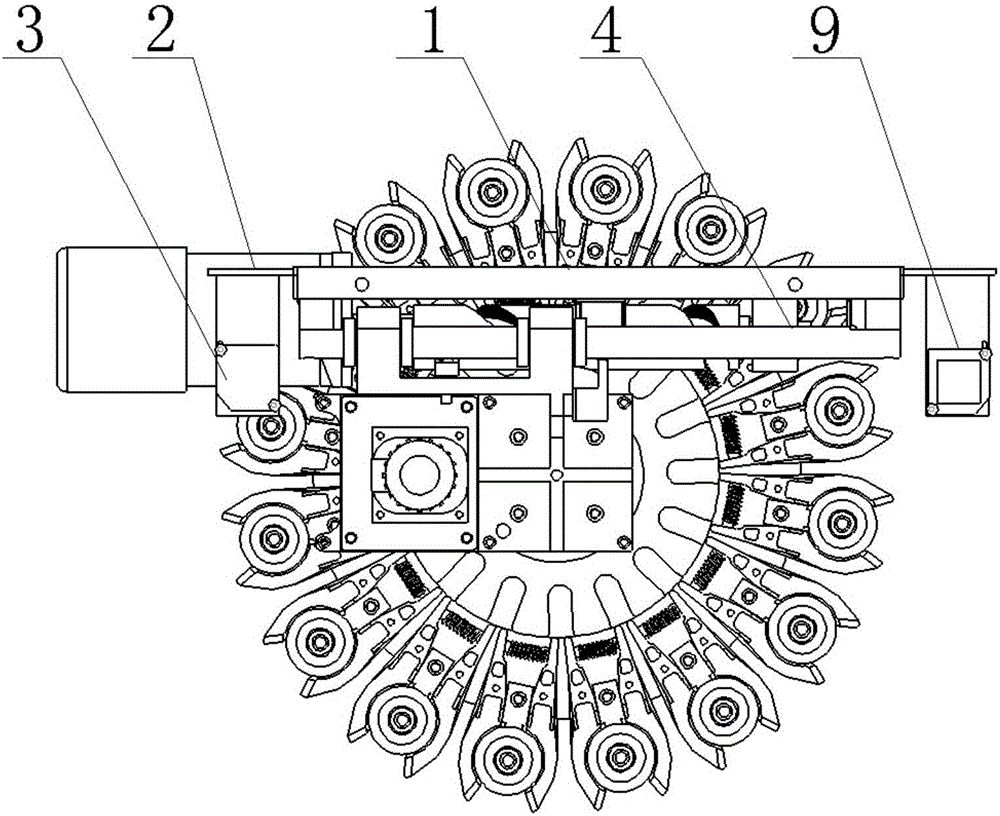

[0020] Such as figure 1 As shown, the detection device includes a tool magazine bracket 1, a sensor bracket 2, a laser displacement sensor A3, a linear bearing 4, a sliding support seat 5, a travel switch touch block 6, a travel switch 7, a guide shaft 8, a laser displacement sensor B9, data Acquisition card 10, industrial computer 11, cylindrical groove cam 12. Such as figure 1 and figure 2 It can be seen from the sectional view that the tool magazine support 1 is fixed on the tool magazine base, and the cylindrical grooved cam 12 is loaded into the bearing of the tool magazine bracket 1 so that it can rotate freely. Install the linear bearing 4 on the sliding support seat 5 and fix the above two parts together through the stop ring, and finally insert the linear bearing 4 into the guide rail shaft. The tool magazine support 1 can move forward and backward a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com