Quartz stone sample polishing and coating equipment and processing method

A coating equipment, quartz stone technology, applied in grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problem that the corners cannot be well treated, the appearance quality cannot be fully guaranteed, and the sample delivery It is easy to cross dislocation and other problems to achieve effective and uniform polishing, better appearance, and crystal clear surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the embodiments described here are only used to explain the present invention, not to limit the present invention.

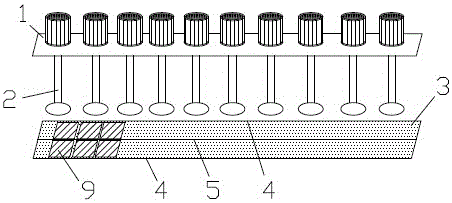

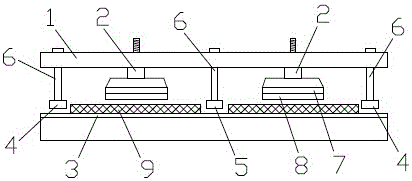

[0019] Such as Figure 1-2 As shown, the quartz stone sample block polishing and coating equipment main body includes a frame 1, a grinding disc 2 and a conveyor belt 3, and the grinding discs 2 are several groups, which are arranged under the frame 1; the conveyor belt 3 is located on Below the grinding table 2, it also includes a fixed side bar 4 and a partition side bar 5 arranged below the frame 1, wherein the fixed side bar 4 is connected to the frame 1 through a connecting column 6, and is hung on the The top of the two sides of the conveyor belt 3; the 5 partitions are several, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com