An automatic centering clamping mechanism

A clamping mechanism and automatic centering technology, applied in workpiece clamping devices, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of high labor intensity and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] This embodiment is an automatic centering clamping mechanism, which can realize the automatic rounding of cylindrical and shell parts during the clamping process.

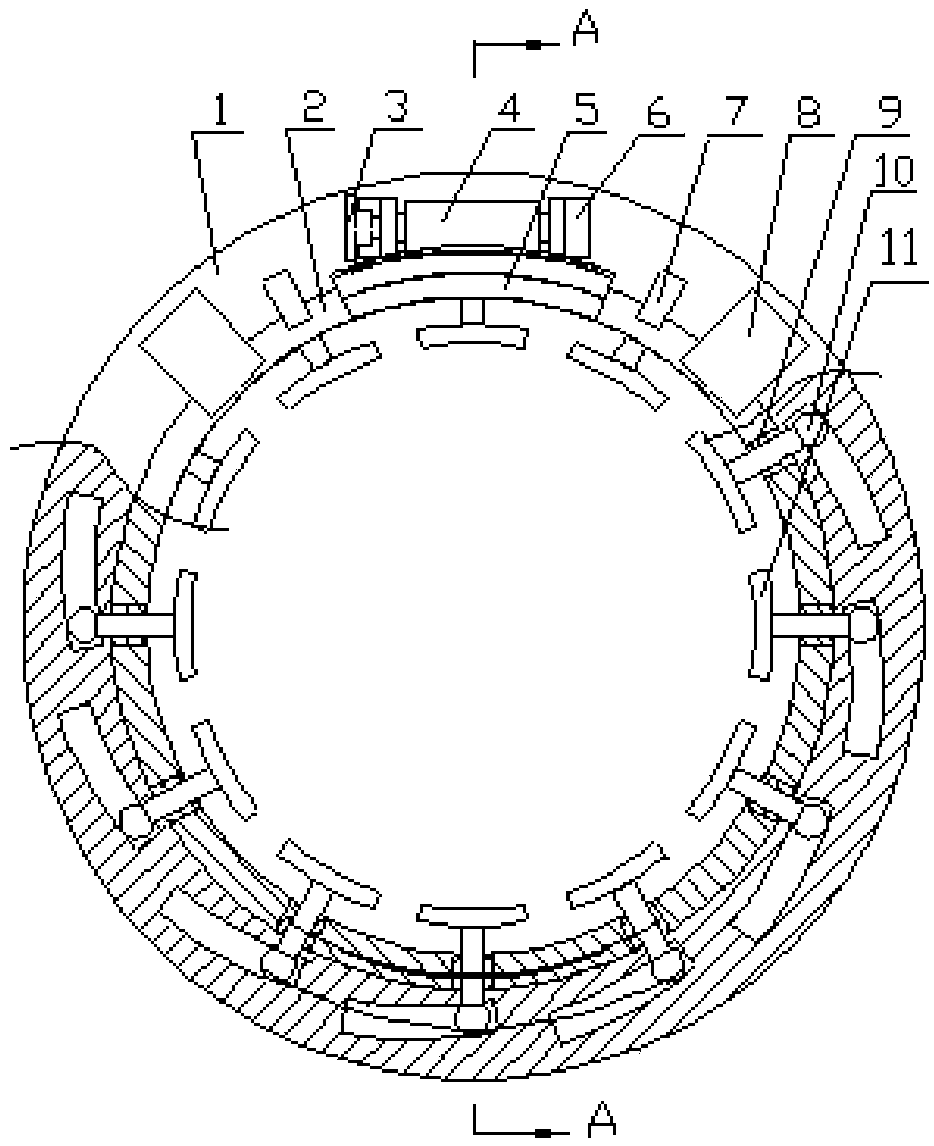

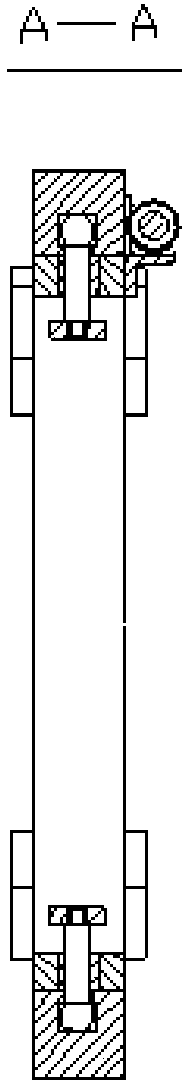

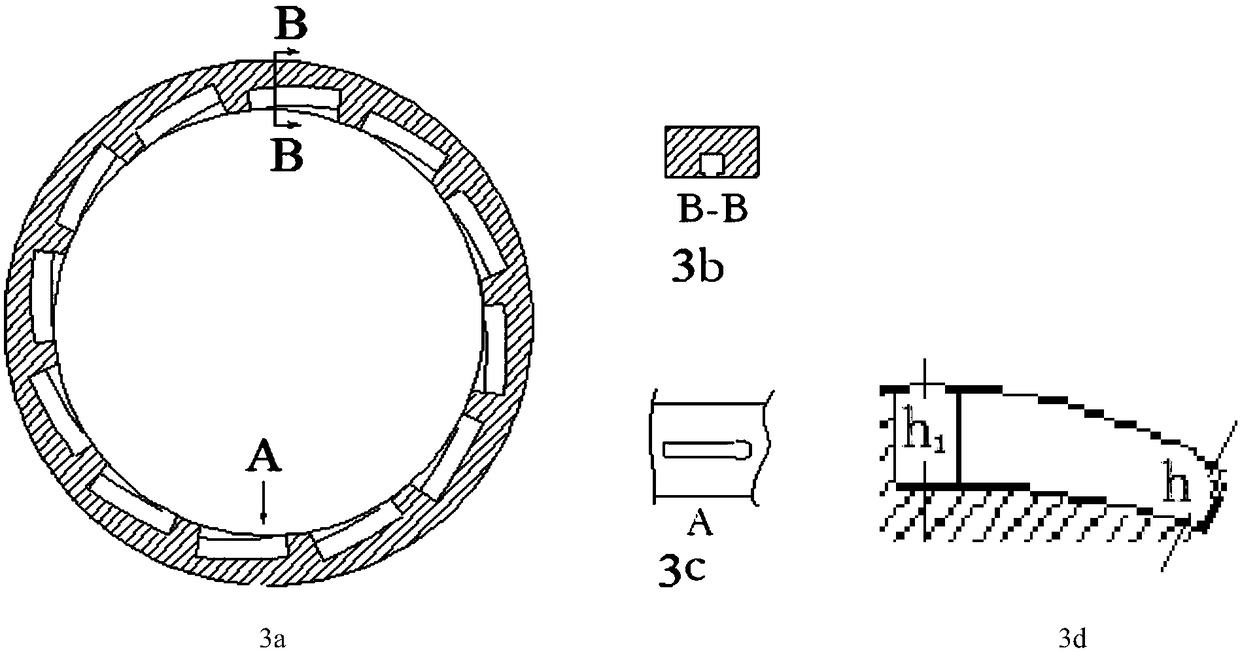

[0020] This embodiment includes an outer ring body 1, an inner ring body 2, a hand wheel 3, a worm 4, a worm gear body 5, a bearing seat 6, a guide sleeve 9, a limiter 7, an axial stopper 8 and a telescopic body. The telescopic body includes a telescopic shaft 10 and a clamping block 11 . Wherein, the outer ring body 1 is sleeved on the outer peripheral surface of the inner ring body 2, and there is a clearance fit between the two. The ball ends of the telescopic shafts 10 in the plurality of telescopic bodies pass through the guide holes on the circumference of the inner ring body 2 and are loaded into each chute on the inner surface of the outer ring body 1 . The worm gear body 5 is fixed on the end face of the inner ring body 2; the worm 4 is fixed on the end face of the outer ring body 1 through the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com