Plastic pipe following copying double-cutting device

A cutting device and plastic pipe technology, which is applied in metal processing and other directions, can solve the problems of knife jamming, roundness and ellipticity deviation, and end surface coking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

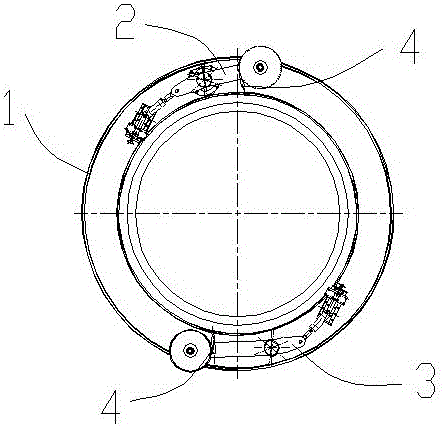

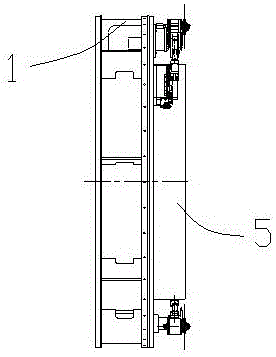

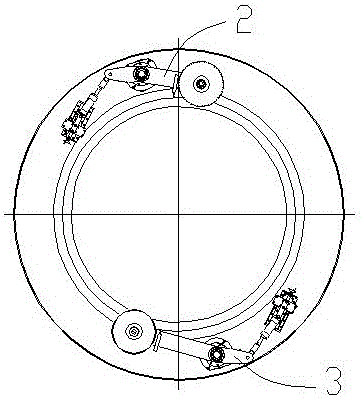

[0033] In this embodiment, a kind of profile-following double-cutting device for plastic pipes, see figure 1 or image 3 , arranged on the rotary table 1 of the cutting machine, wherein the hydraulic control and module control system are installed in the middle of the support plate of the rotary table 1 of the cutting machine, and the profiling saw blade cutting device 2 and the profiling blade cutting device 3 are symmetrically installed on the cutting machine up and down On the front face of the turntable 1. The profiling displacement sensing device 4 is respectively configured on the profiling saw blade cutting device 2 and the profiling blade cutting device 3, and when the pipe material 5 product obtains a cutting signal, the two cutting devices detect according to the profiling displacement sensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com