Comb gulleting machine

A technology of comb and tooth spacing, which is applied in the field of comb gear cutting machine, which can solve the problems such as the inability to adjust the radian of the tooth cutting machine, the complex structure of the gear cutting machine, and the large footprint, so as to achieve long service life, use safety and operation stability Good, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

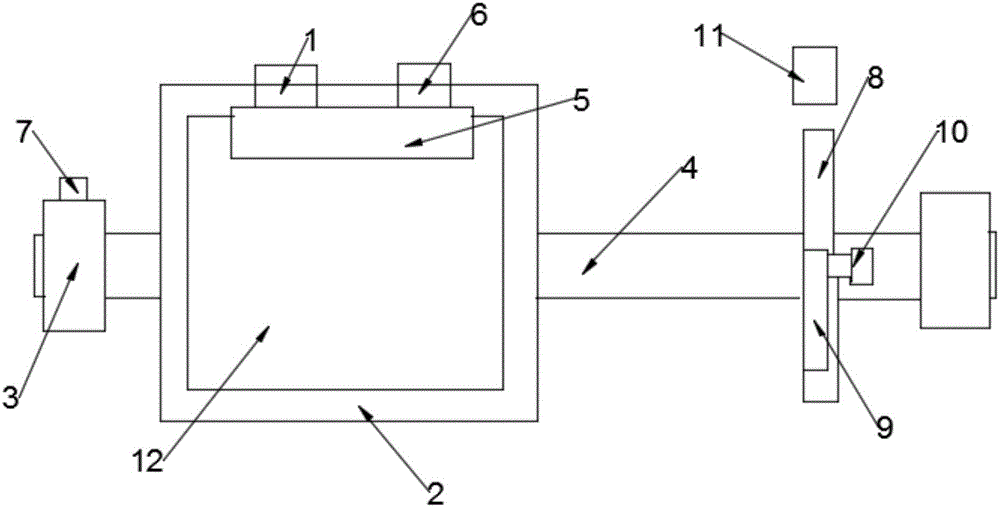

[0013] see figure 1 , a comb gear opening machine, including a workbench 2, a raw material device 3, a cutting device 5, a lead screw 4, a lead screw drive device, a pallet frame 12, a tooth spacing adjustment device 1, an arc adjustment device 6 and a raw material control device 7 , the cutting device 5, the lead screw 4, the lead screw driving device, the pallet frame 12, the tooth spacing adjustment device 1 and the radian adjustment device 6 are all installed on the workbench 2, and the pallet frame 12 is installed on the On the upper end of the workbench 2, the workbench 2 is provided with a lead screw 4 for transmission, the lead screw 4 is connected with the lead screw driving device, the raw material device 3 is located at one end of the lead screw 4 and the raw material device 3 is connected with the raw material control device 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com