Special laminating machine for decoration sheet material

A laminating machine and plate technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of normal engraving of knives, reduction of jewelry yield, uneven lamination, etc., to improve engraving efficiency and smoothness Improve performance and ensure the effect of engraving work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

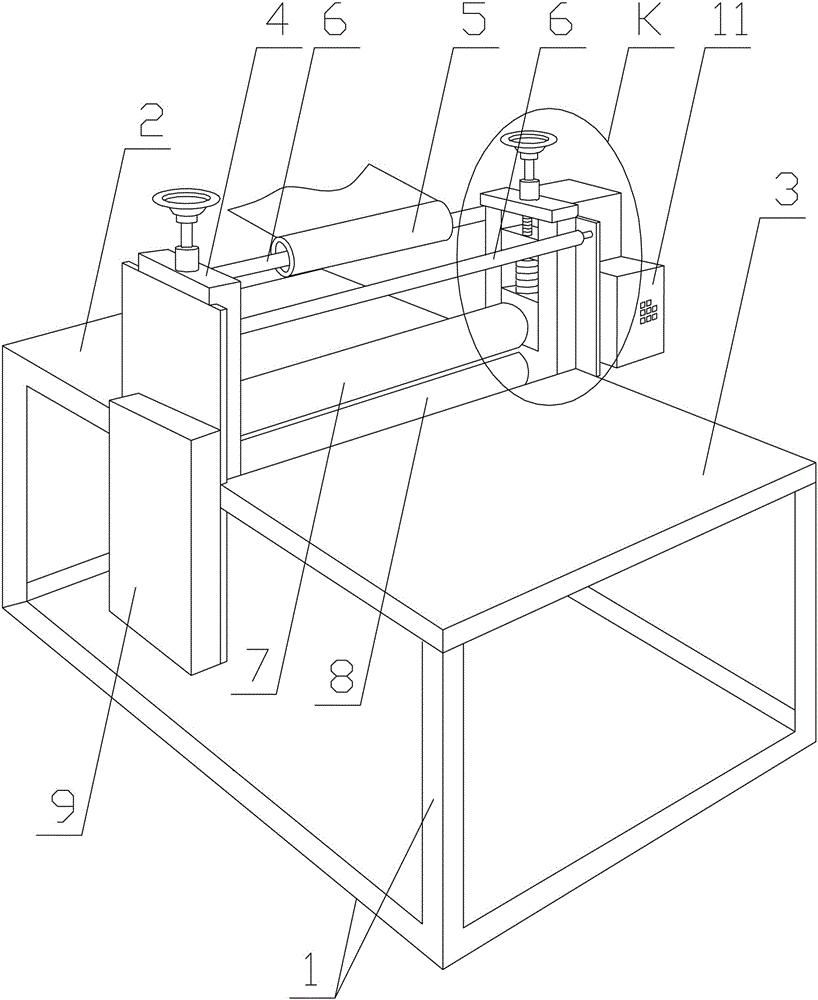

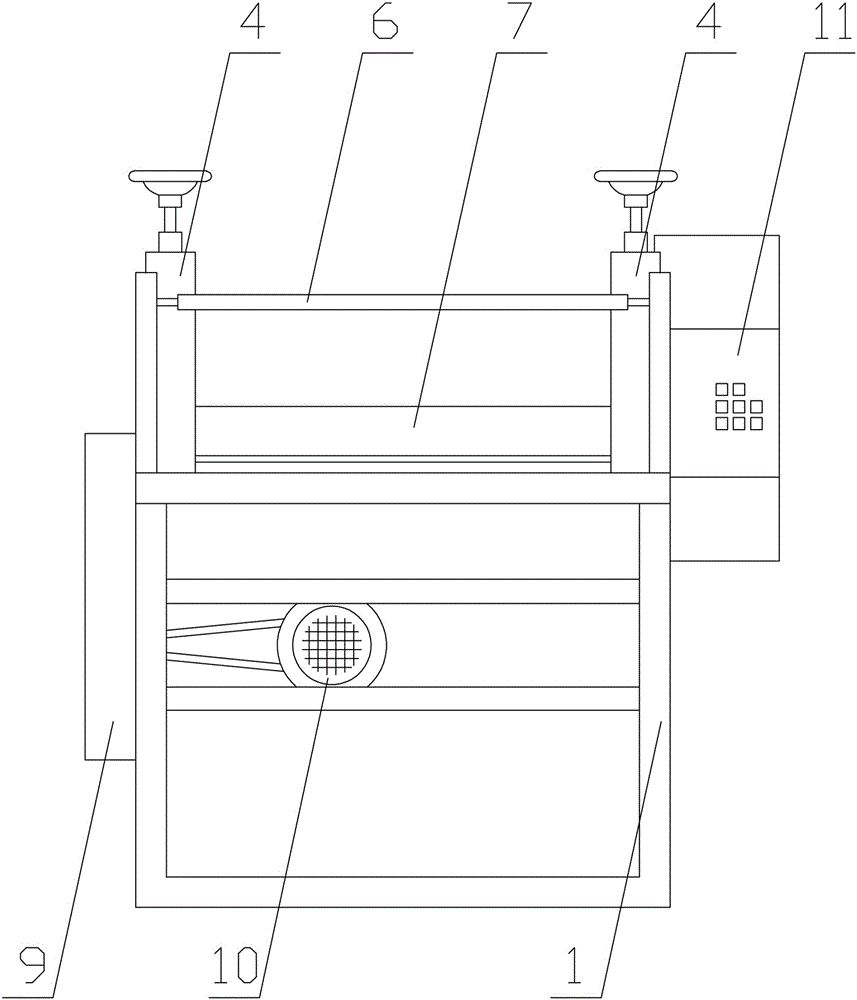

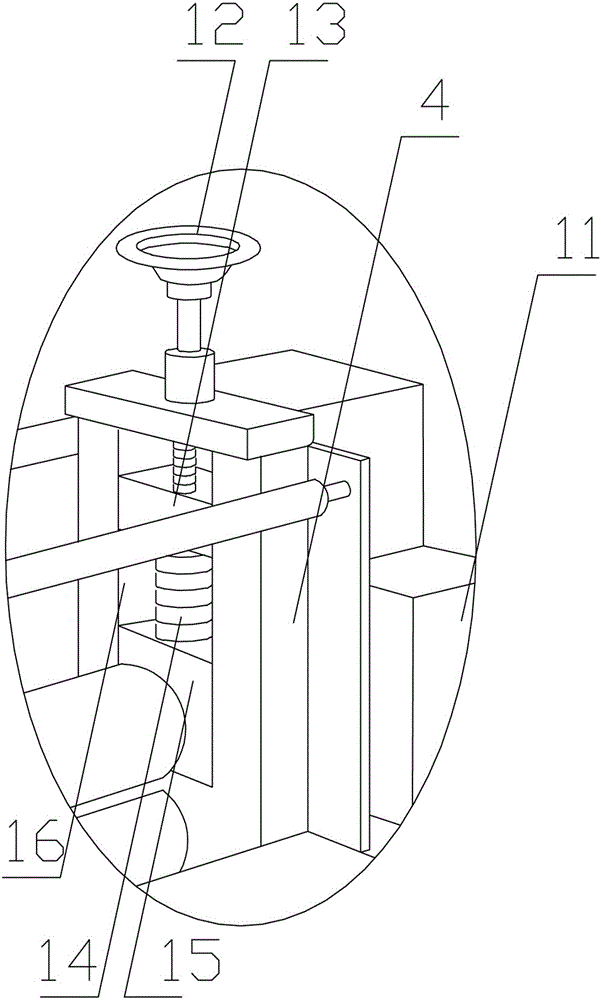

[0014] see Figure 1-3 , the present invention has frame 1, is arranged with left and right working platform 2,3 on the frame 1, is provided with two supports 4 that front and back are correspondingly arranged at the joint of left and right working platform 2,3, and is arranged on two A film winding rod 6 and two rubber rollers for fixing the adhesive film roller 5 are arranged between the support 4, wherein the two rubber rollers are the upper side driven rubber roller 7 and the lower side driving rubber roller 8, and on the two The support 4 is equipped with an adjustment device for adjusting the upper and lower gaps between the two rubber rollers; the active rubber roller 8 forms a driving connection with the speed regulating motor 10 through the gear box 9, and the speed regulating motor 10 is driven and controlled by the frequency converter 11, wherein The gear box 9, the speed regulating motor 10 and the frequency converter 11 are all installed on the frame 1.

[0015] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap