Electromechanical commutator for oil pumping unit

A technology of pumping unit and commutator, which is applied in mechanical equipment, production fluid, gear transmission, etc., can solve the problems such as the influence of the life of the power grid operation motor, energy loss, and difficulty of frequent forward and reverse rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments.

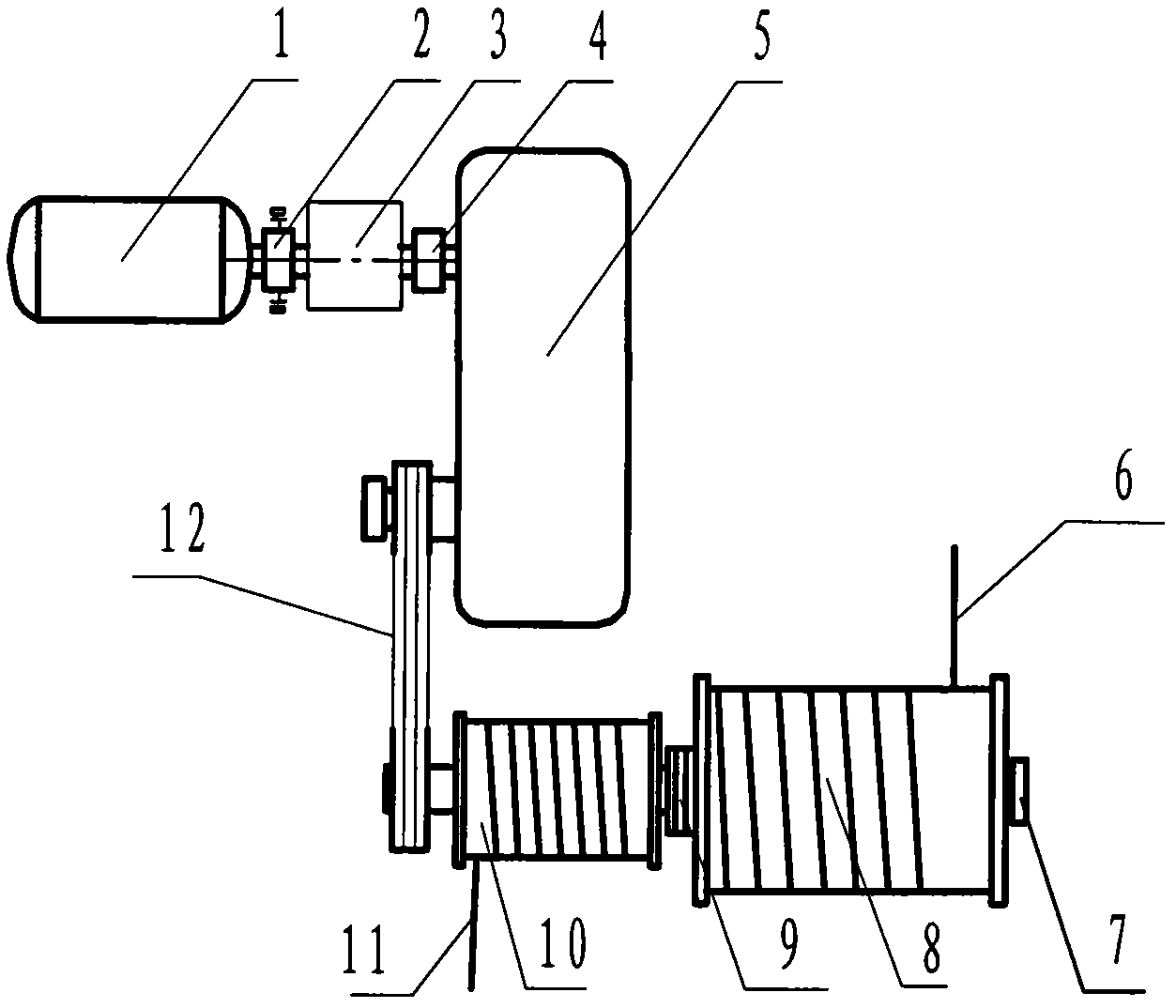

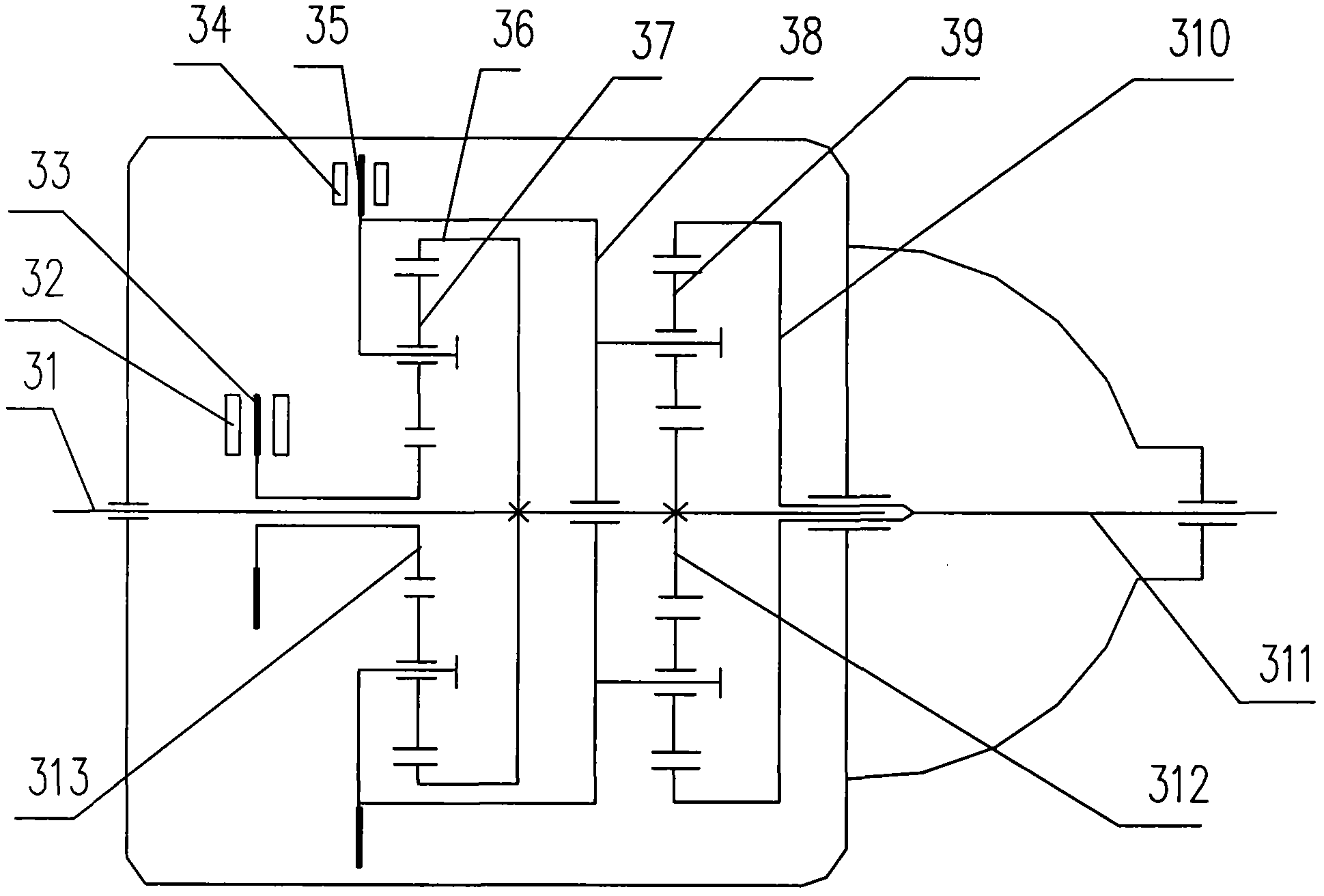

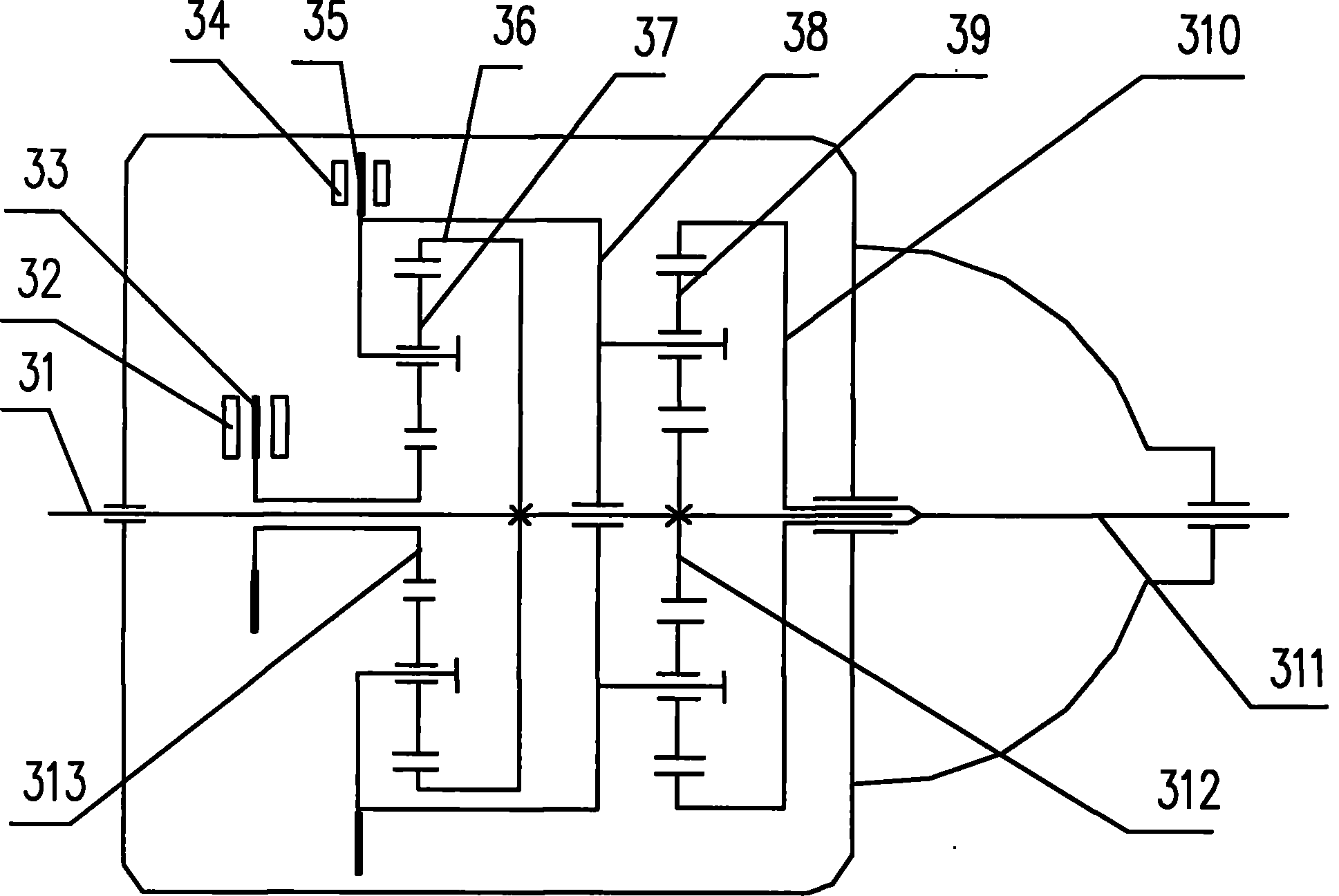

[0020] Such as figure 1 As shown, the electromechanical pumping unit commutator 3 involved in the present invention is installed between the electric motor 1 and the reduction box 5 of the reciprocating rotary pumping unit. The input shaft 31 of the commutator 3 of the electromechanical pumping unit is connected with the motor 1 through the coupling 2 with a normally closed electromagnetic brake, and is connected with the reduction box 5 through the coupling 4 . The motor 1 rotates normally, through the positive and negative rotation of the output shaft 311 of the electromechanical pumping unit commutator 3, through the reduction box 5 and the belt 12, the production drum 10 and the balance drum 8 are driven forward and reverse. The production drum 10 winds or releases the production wire rope 11 to drive the sucker rod of the pumping unit to move up and down in a recipr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com