Full-automatic tank winding machine

A winding machine, fully automatic technology, applied in the direction of rotating wrapping of articles, spraying devices, etc., can solve the problems of increased production cost, low work efficiency, manual winding, etc., and achieves the effects of convenient connection, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

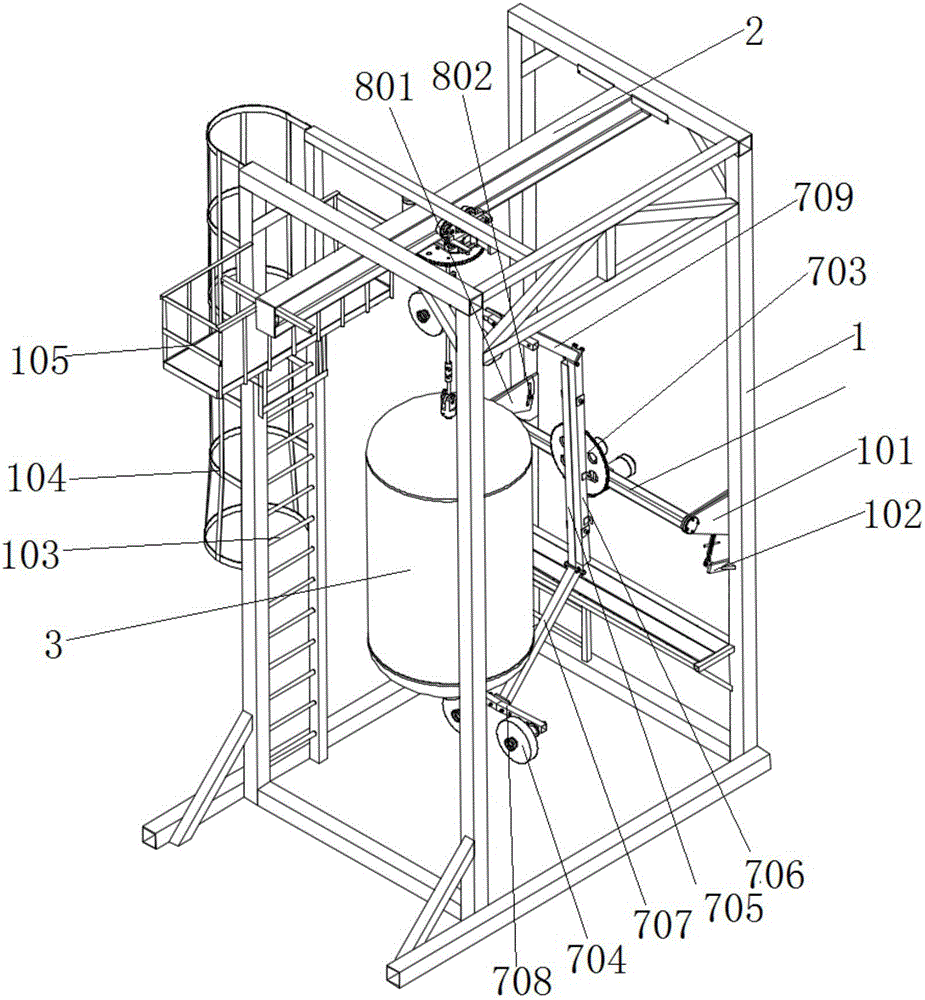

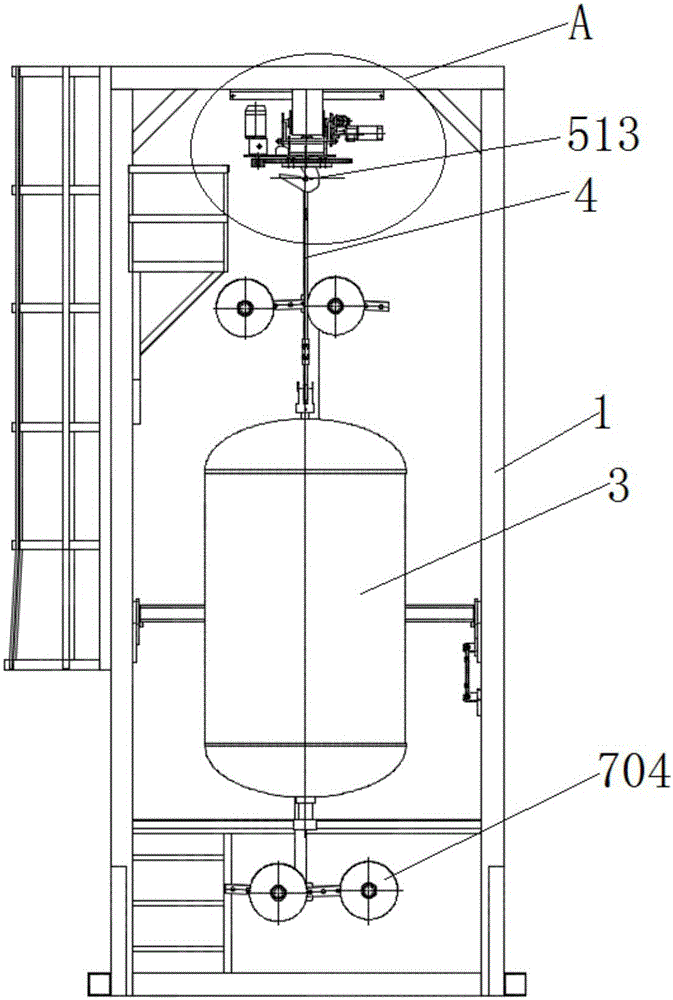

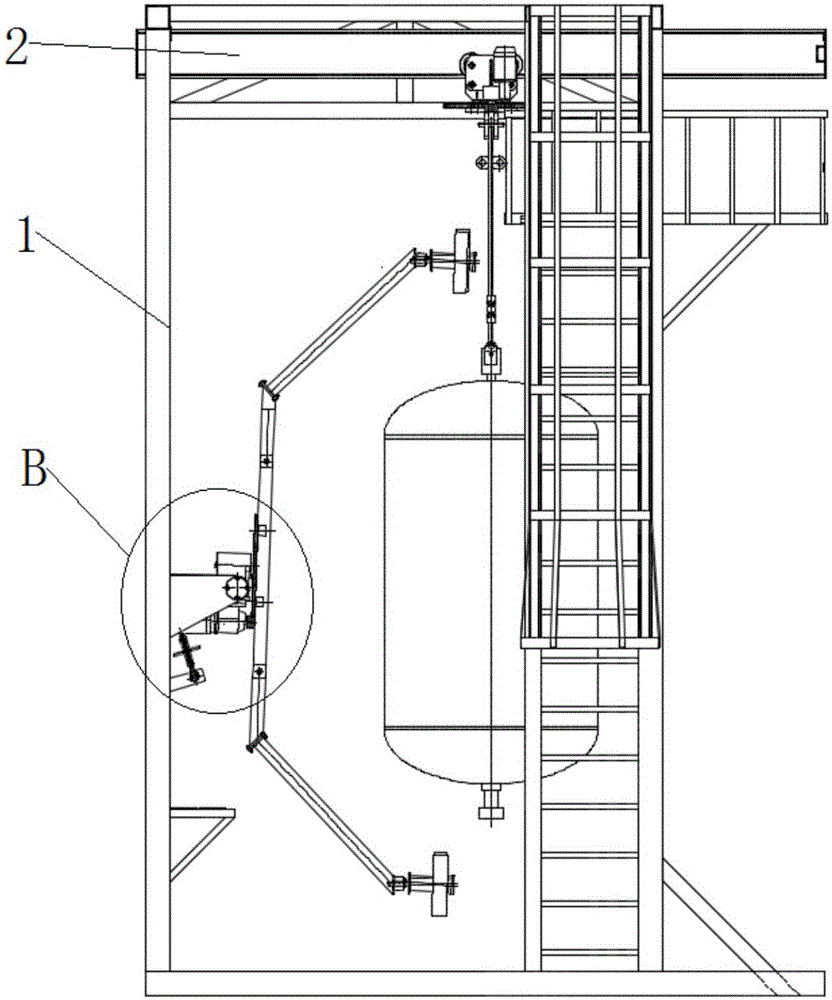

[0030] combine figure 1 , figure 2 , image 3 with Figure 4 , a kind of full-automatic tank winding machine of the present embodiment, comprises the support frame 1 of cube structure, and support frame is made of left side frame, right side frame, the front bottom bar that connects left side frame, right side frame , the rear bottom bar and the front side frame, a ladder 103 is provided on the rear side of the support frame 1, and guardrails 104 are provided around the ladder 103; Maintenance personnel maintain the standing platform 105 of the mobile rotating device;

[0031] The guide rail 2 arranged in the left and right directions is arranged in the support frame 1, and the guide rail 2 is fixed at the middle position of the top of the support frame 1. In this embodiment, the guide rail adopts medium carbon alloy steel (42CrMo) as the manufacturing material of the guide rail, and is carried out Quenching and tempering treatment, hardness HB320-360, to ensure sufficien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com