Automatic pipe winding and packing assembly line

An assembly line and pipe technology, which is applied in the direction of strapping materials, parts of strapping machinery, paper/cardboard containers, etc., can solve the problems of high labor intensity and long time, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

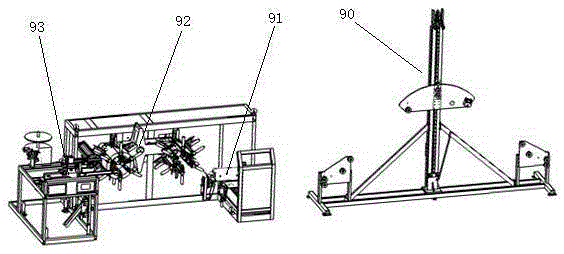

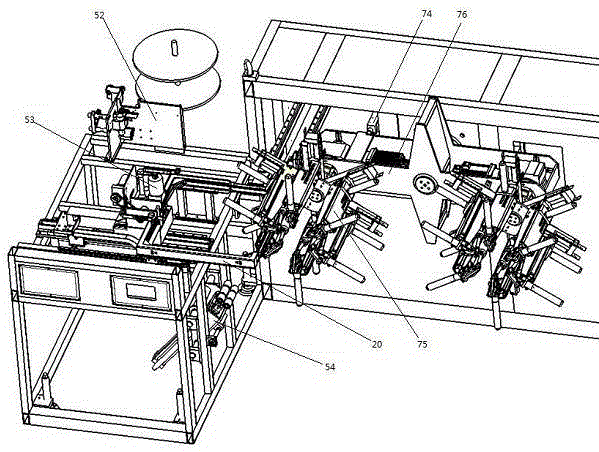

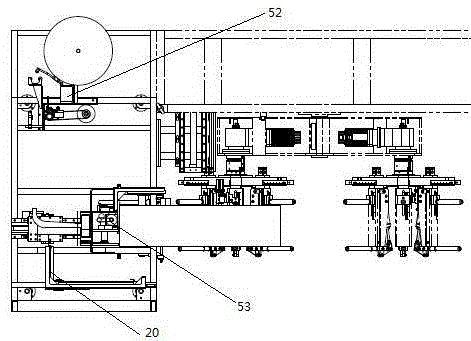

[0065] Such as Figure 1 to Figure 19 As shown, an automatic pipe rewinding and packaging line includes a pipe storage device 90, a wire and pipe delivery device 91, a winding device 92, and a packaging device 93 arranged in sequence from right to left. The pipe storage device 90 is stored to be collected. For the rolled pipes, the wire arranging and pipe feeding device 91 carries out arranging and conveying of the pipes so that they are neatly arranged during the rewinding process of the rewinding device. disc 75, and the pipes are wound on the reel, and the packing device 93 packs the pipes that have been rewound in the reel.

[0066] The baling device 93 includes a tape storage mechanism 52 installed on the frame 1, a bale main body 53, a tape guide frame 20, a pressure tube assembly 54 and a positioning assembly 74. The pipes 30 on the disc 75 make the pipes to be bundled partly located in the closed-loop structure, and the strapping belt is worn in the guide frame, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com