Wire rope core tape joint connection method

A steel wire rope core and joint connection technology is applied in the joint field of mining flame retardant steel wire rope core tape, which can solve the problems of destroying the breaking force of the steel wire rope, affecting the quality of the joint, and breaking the wire of the drawing rope, so as to increase the friction force, ensure the safety of the joint, The effect of increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

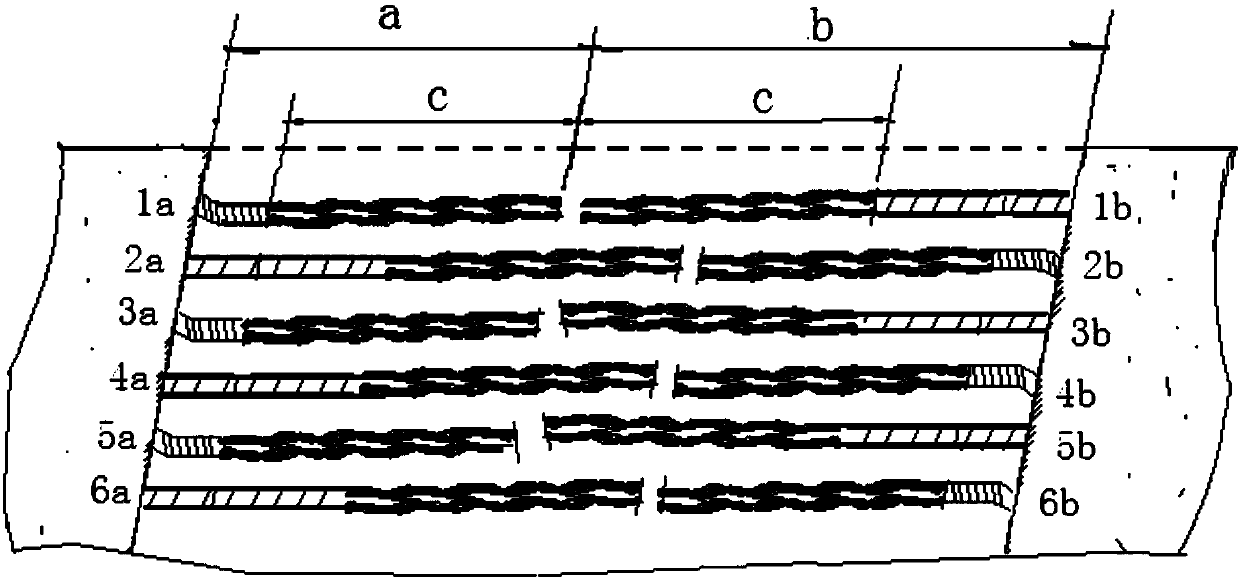

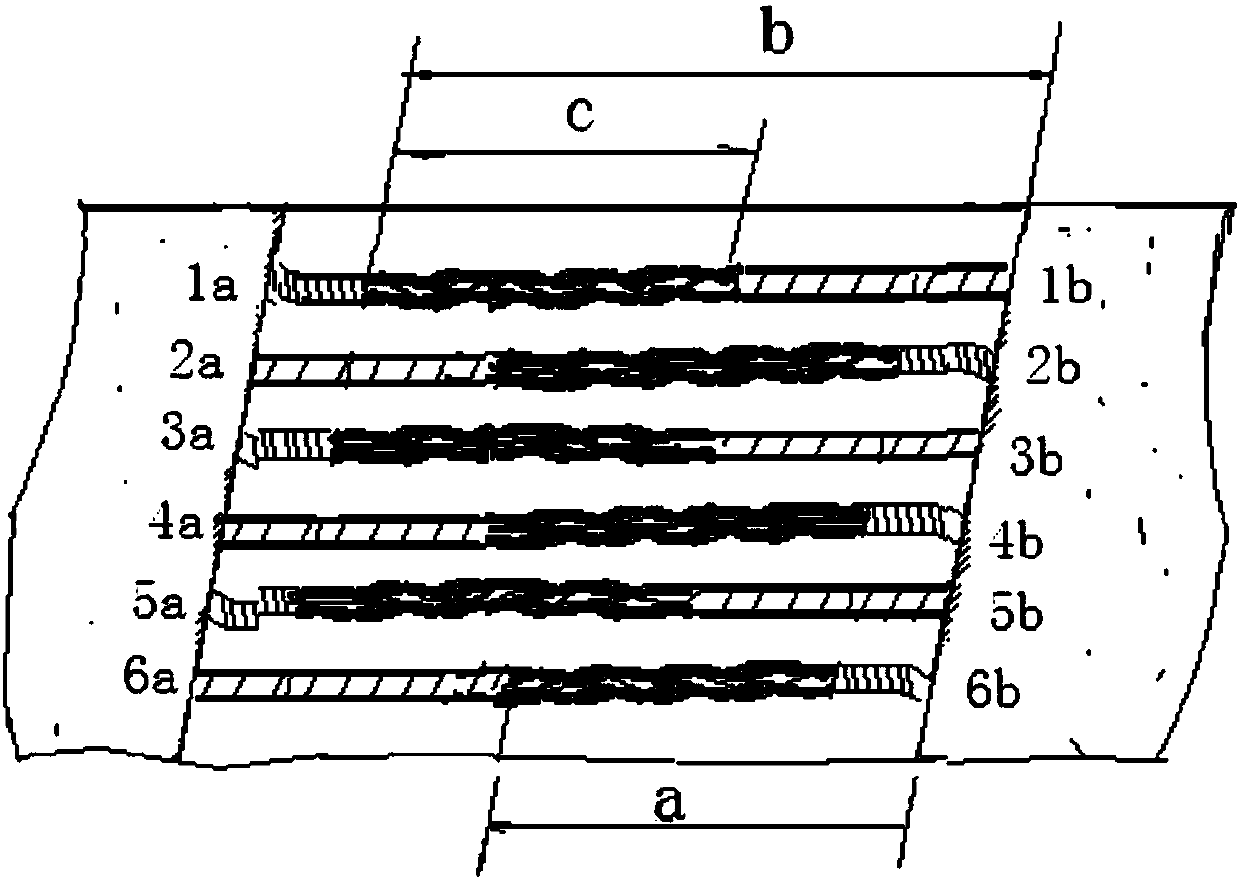

[0016] Step 1: First, fix the two joints of the steel cord tape firmly to prevent movement, and remove the glue at the joints to expose a certain length of the steel cord. The six steel cords on the left are respectively counted as 1a, 2a, 3a, and 4a , 5a, 6a; the six wire ropes on the right are respectively counted as 1b, 2b, 3b, 4b, 5b, 6b;

[0017] The second step: keep 1a, 3a, 5a and 2b, 4b, 6b according to the length of a=0.9m; keep 2a, 4a, 6a and 1b, 3b, 5b according to the length of b=1.5m;

[0018] The third step: Divide 1a, 3a, 5a and 2b, 4b, 6b steel wire rope cores into 3 strands for strand breaking, divide 2a, 4a, 6a and 1b, 3b, 5b steel wire rope cores into 4 strands for strand breaking; or divide 1a, 3a, 5a and 2b, 4b, 6b steel wire rope cores are divided into 4 strands for strand breaking, 2a, 4a, 6a and 1b, 3b, 5b steel wire rope cores are divided into 3 strands for strand breaking, and the strand length c=800mm;

[0019] Step 4: After the strands of the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com