Paper feeding method lowering lifting plates at same time and elevating lifting plates at different time

A technology of paper feeding and paper feeding wheel, applied in the direction of pile separation, object separation, object supply, etc., can solve the problem of cardboard damage, etc., achieve the effect of improving paper feeding quality, simplifying the mechanical structure, and enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

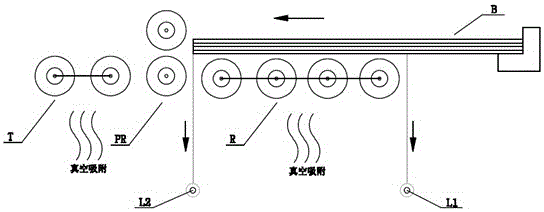

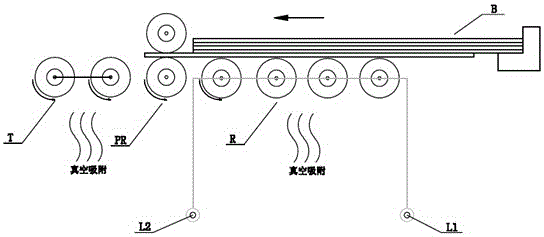

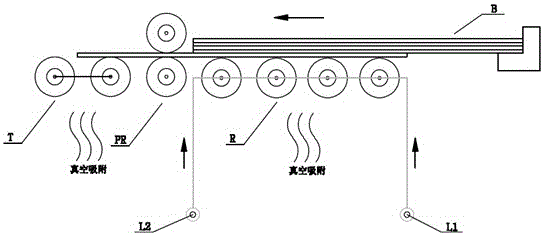

[0031] The accompanying drawings are for illustrative purposes only, and should not be construed as limitations on this patent; in order to better illustrate this embodiment, certain components in the accompanying drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art It is understandable that some well-known structures and descriptions thereof may be omitted in the drawings. The positional relationship described in the drawings is for illustrative purposes only, and should not be construed as a limitation on this patent.

[0032] Such as Figure 5 As shown in -13, a paper feeding method of simultaneously descending and time-sharing ascending and lifting boards, which includes the following steps:

[0033] Such as Figure 5 , S1. The first paper feed roller R1 and the second paper feed roller R2, the first grid lifting plate L1 and the second grid lifting plate L2 are all in a static state, and the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com