A slag drainage device for slag wool and its application method

A technology of slag wool and slag, which is applied in the field of metallurgical slag, can solve the problems of inability to realize online heating and long-distance transportation of slag, adverse effects of the overall process layout scheme, and reduce the ratio of sensible heat utilization of slag, achieving obvious economical Benefits and promotional use value, obvious economic benefits and environmental benefits, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

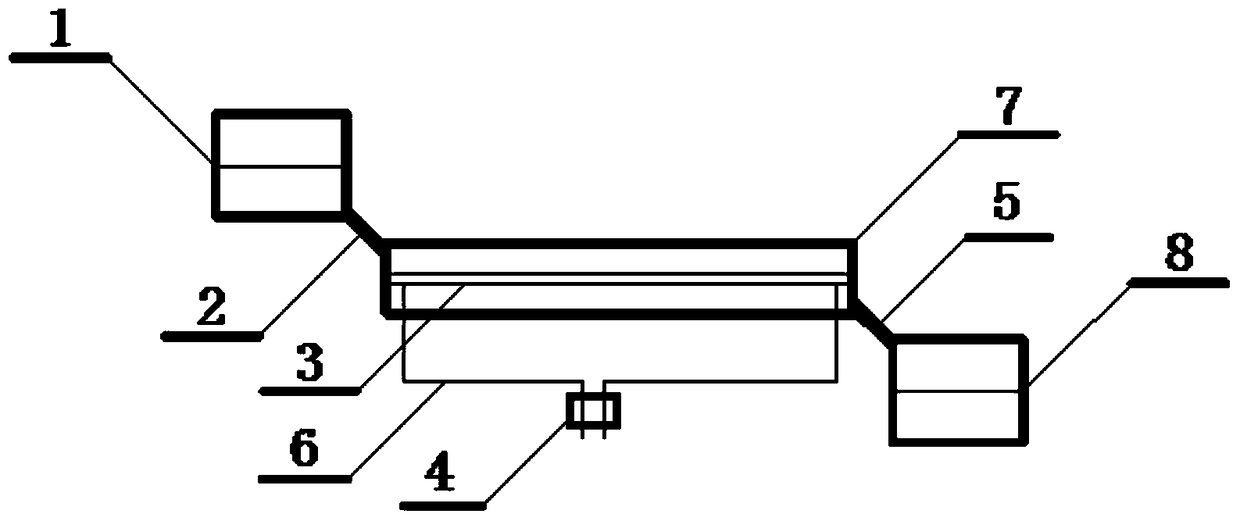

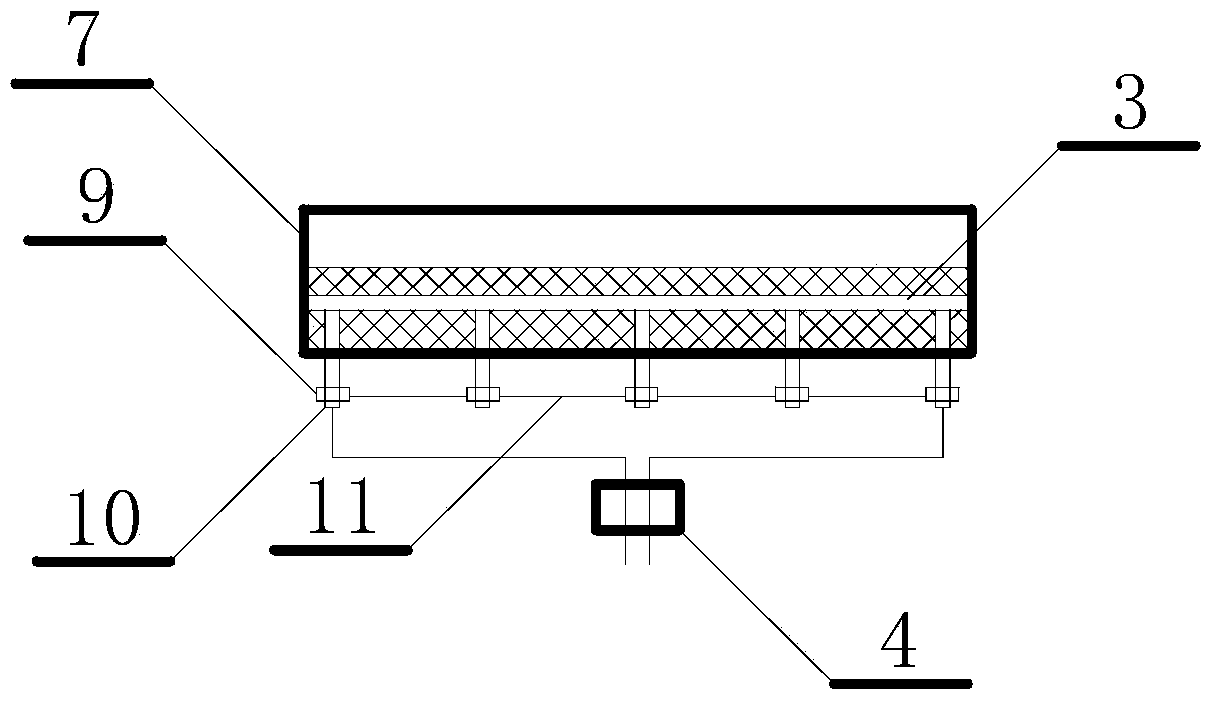

[0035] A slag drainage device for slag wool and a method of use, such as figure 1 , figure 2 As shown, the heater 3 (10mm diameter stainless steel rod) is connected with the power controller 4 through the stainless steel support rod 10 and the heating wire 6, and the insulating gasket 9 can ensure the insulation between the support rod 10 and the support plate 11 to ensure Overall device safety.

[0036] The installed heater 3 has the same length as the slag tapping tank 7. After inspection, there is no leakage between the slag tapping tank 7, the heater 3, and the support plate 11.

[0037] When the slag flows from the slag container 1 through the slag guide groove 2 into the slag groove 7, the temperature is about 1550°C, the slag completely submerges the heater 3, and the height of the center of the heater 3 is 1 / 1 of the height of the slag liquid level. 2. When 220V AC is supplied, the heat emitted by the heater 3 keeps the surrounding slag above 1450°C. The slag has g...

Embodiment 2

[0039] A slag drainage device for slag wool and a method of use, such as figure 1 , figure 2 As shown, the heater 3 (side length is 8mm Q235 square steel) is connected with the power controller 4 through the stainless steel support rod 10 and the heating wire 6, and the insulating gasket 9 can ensure that the support rod 10 and the support plate 11 are kept insulated. Ensure the safety of the overall device.

[0040] The installed heater 3 is slightly shorter than the slag tapping tank 7. After inspection, there is no leakage between the slag tapping tank 7, the heater 3 and the support plate 11.

[0041] When the slag flows from the slag container 1 through the slag guide groove 2 into the slag groove 7, the temperature is about 1530°C, the slag completely submerges the heater 3, and the center height of the heater 3 is 1 / 1 of the height of the slag liquid surface. 3. After the 220V direct current is supplied, the heat emitted by the heater 3 keeps the surrounding slag ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com