A method for preparing carbon fiber and hydrogen by catalytic cracking of low-carbon hydrocarbons

A technology for catalytic cracking and low-carbon hydrocarbons, applied in chemical instruments and methods, chemical characteristics of fibers, catalysts for physical/chemical processes, etc., to achieve the effects of wide application range of raw materials, low price and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Get semi-coke from Yulin, northern Shaanxi (the bulk semi-coke of Wuzhou Coal Chemical Co., Ltd., Shenmu County, see Table 1 for industrial analysis and elemental analysis, it belongs to a kind of low-temperature pyrolysis semi-coke in coal, the same below) as the raw material for catalyst preparation , crushed and sieved into particles of 70-150 μm. According to the mass ratio of 1:1, weigh the semi-coke particles and Na 2 CO 3 (analytical pure), and simultaneously added to the water-ethanol binary solution (the volume ratio of water and ethanol is 5:1), stirred and mixed for 10 h, and then vacuum-dried to form a mixture.

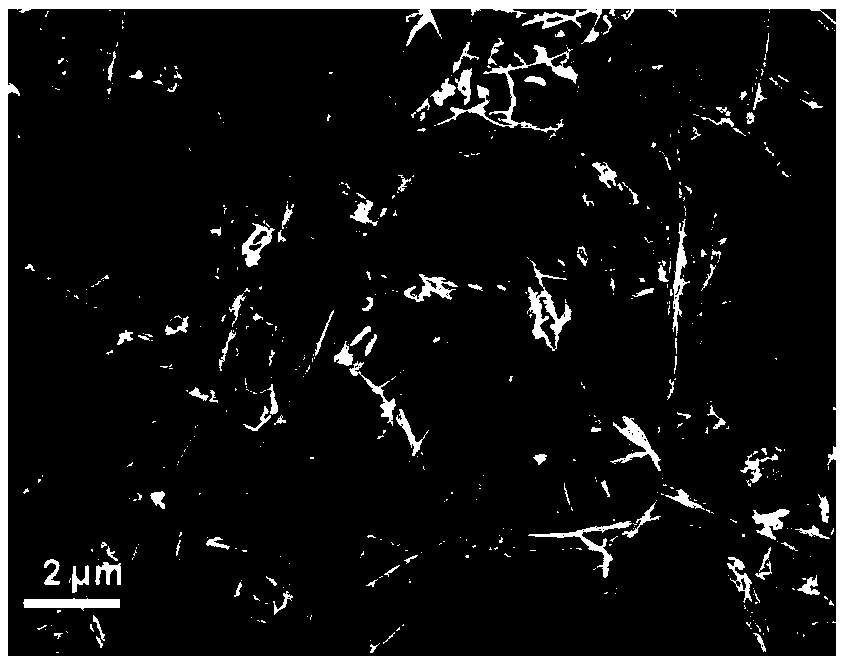

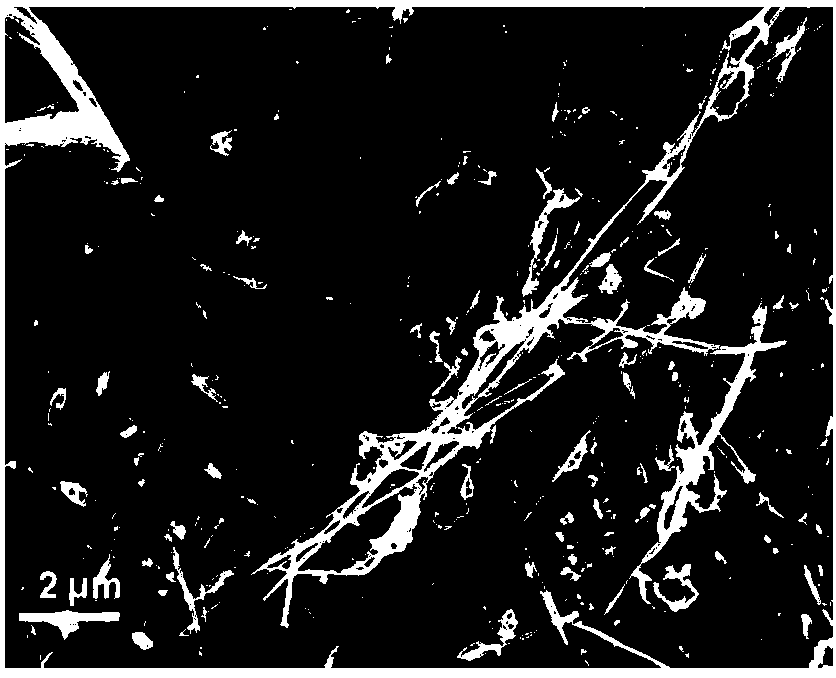

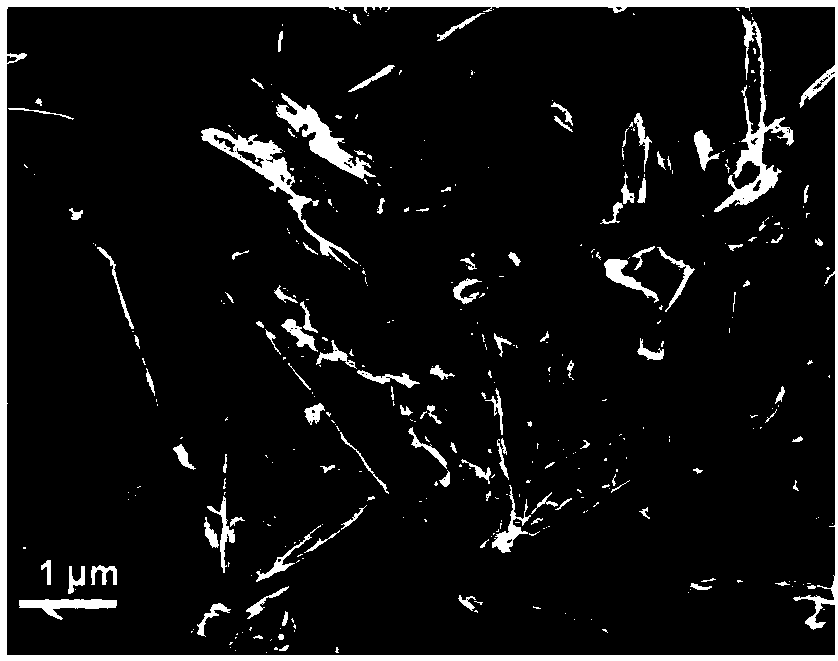

[0035] Then, take the above-mentioned mixture that is 5g in quality and use it as a catalyst for catalytic methane cracking reaction, and react in a traditional fixed-bed reactor. 300L / (h·g cat ). Collect the gas generated by methane cracking reaction to obtain hydrogen-rich gas; under this condition, within 10 hours of reaction, the methane con...

Embodiment 2

[0040] The semi-coke from Yulin in northern Shaanxi is used as the raw material for catalyst preparation, which is crushed and sieved into particles of 180-300 μm. According to the mass ratio of 1:5, weigh the semi-coke particles and K 2 CO 3 (analytical pure), and simultaneously added to the water-ethanol binary solution (the volume ratio of water and ethanol is 5:1), stirred and mixed for 10 h, and then vacuum-dried to form a mixture.

[0041] Then, take the above-mentioned mixture that is 5g and use it as a catalyst for catalytic methane cracking reaction, and react in a traditional fixed-bed reactor. 100L / (h·g cat ). Collect the gas generated by methane cracking reaction to obtain hydrogen-rich gas; under this condition, within 5 hours of reaction, the methane conversion rate is 88% to 93%, and the hydrogen gas fraction in the reaction gas is 90.3% to 94.7%; After the reaction residue in the reactor was naturally cooled, washed and dried under nitrogen protection, the ...

Embodiment 3

[0043] The semi-coke from Yulin in northern Shaanxi is used as the raw material for catalyst preparation, which is crushed and sieved into particles of 180-300 μm. According to the mass ratio of 1:10, weigh the semi-coke particles and Na 2 CO 3 (Analytical pure), after 0.25h of mechanical mixing by ball mill stirring and grinding, a mixture was formed.

[0044] Then, take the above-mentioned mixture that is 5g in quality and use it as a catalyst for catalyzing the cracking reaction of ethane, and react in a traditional fixed-bed reactor. The reaction space velocity is 10L / (h g cat ). Collect the gas generated by the ethane cracking reaction to obtain hydrogen-rich gas; under this condition, within 3 hours of reaction, the conversion rate of ethane is 96% to 99%, and the hydrogen gas fraction in the reaction gas is 88.2% to 91.0% ; After the reaction residue in the reactor is naturally cooled, washed and dried under the protection of nitrogen successively, the thick sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com