Reservoir area floating garbage collecting device

A technology for garbage collection and reservoir areas, applied in water conservancy projects, cleaning of open water surfaces, construction, etc., can solve problems such as high labor intensity, high labor cost, hidden safety hazards, etc., and achieve the effect of safe and reliable operation and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

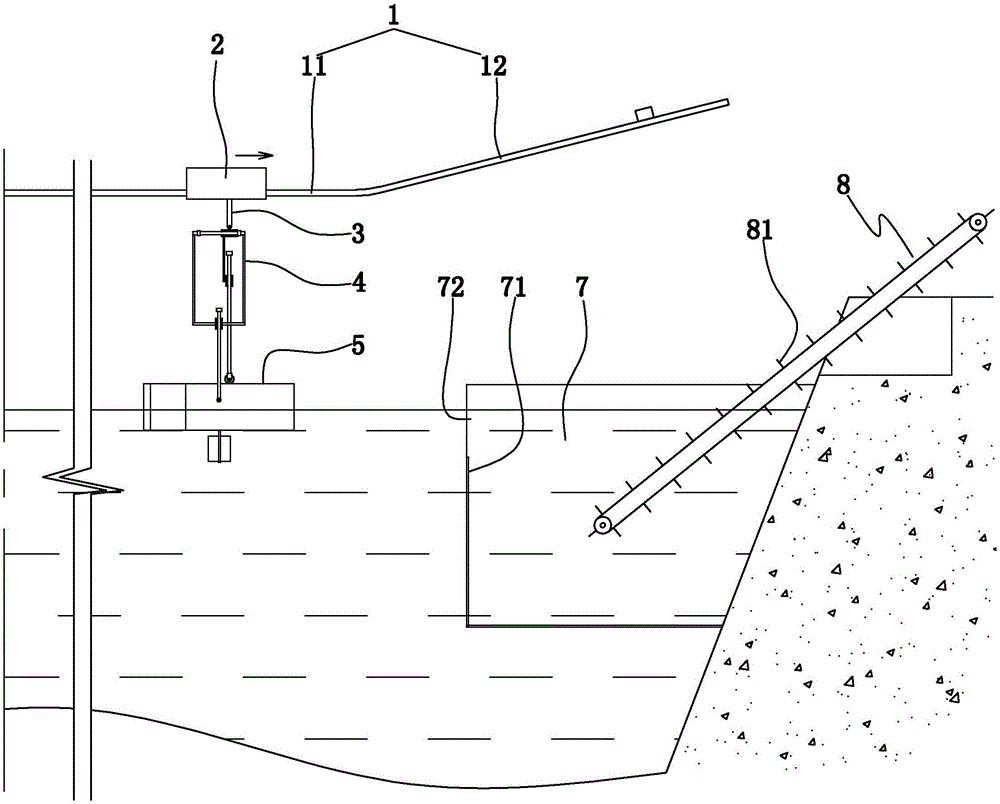

[0024] Such as figure 1 As shown, a floating garbage collection device in the reservoir area includes a driving track 1 located above the water surface, a driving trolley 2 that can walk along the driving track, and a garbage cleaning device. The driving track includes a horizontal track 11 and inclined tracks 12 located at both ends of the horizontal track, and the inclined track extends obliquely upward from the end of the horizontal track. The inclined tracks located at both ends of the horizontal track are arranged symmetrically. The driving track of this embodiment extends along the left-right direction.

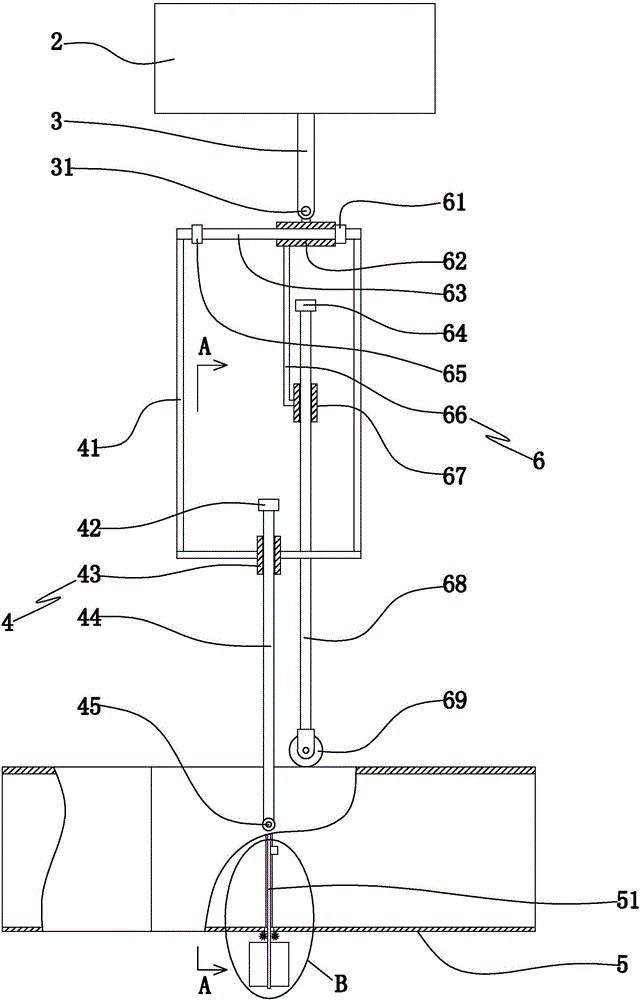

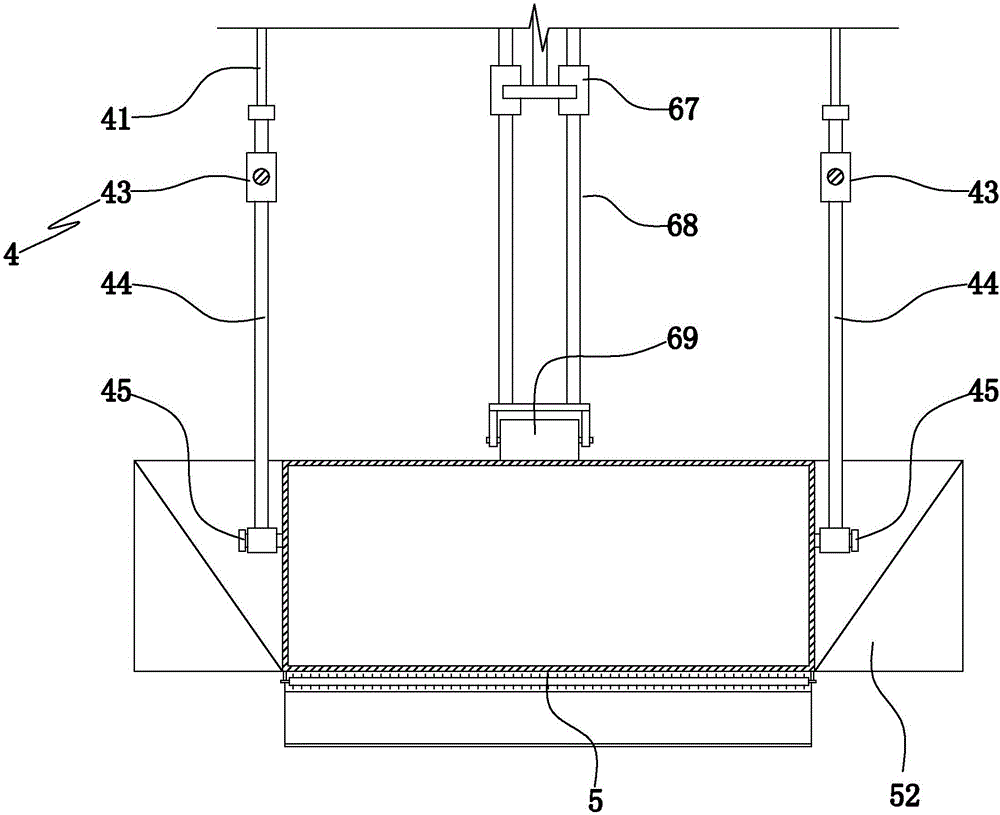

[0025] Such as figure 2 , image 3 As shown, the garbage cleaning device includes a garbage collection casing 5 floating on the water surface and a connection structure connecting the driving trolley and the garbage collection casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com