Prefabricated reinforced concrete structure column and system applying same and construction method of system

A technology of reinforced concrete and structural columns, which is applied in the direction of building structures, columns, pier columns, etc., can solve problems such as integrity to be considered, and achieve the effects of avoiding construction safety problems, obvious economic benefits, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

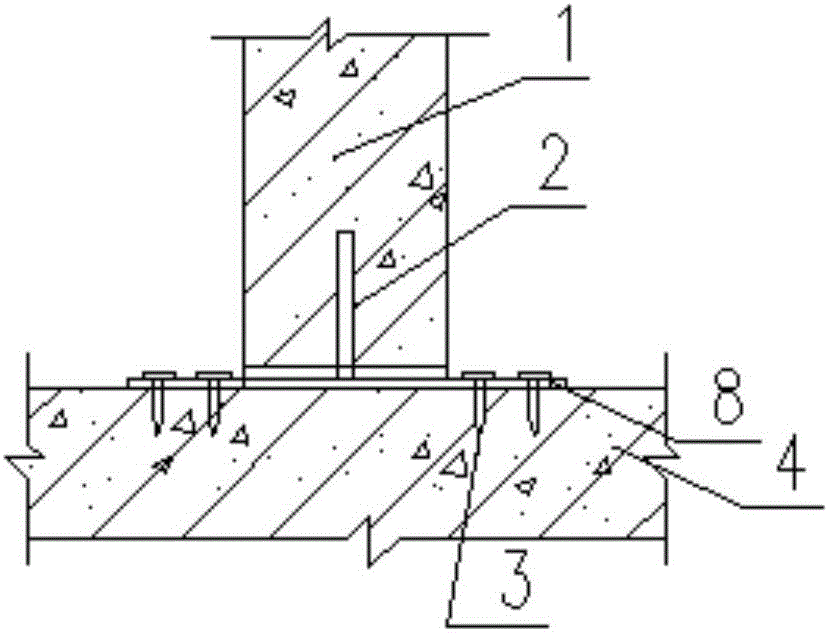

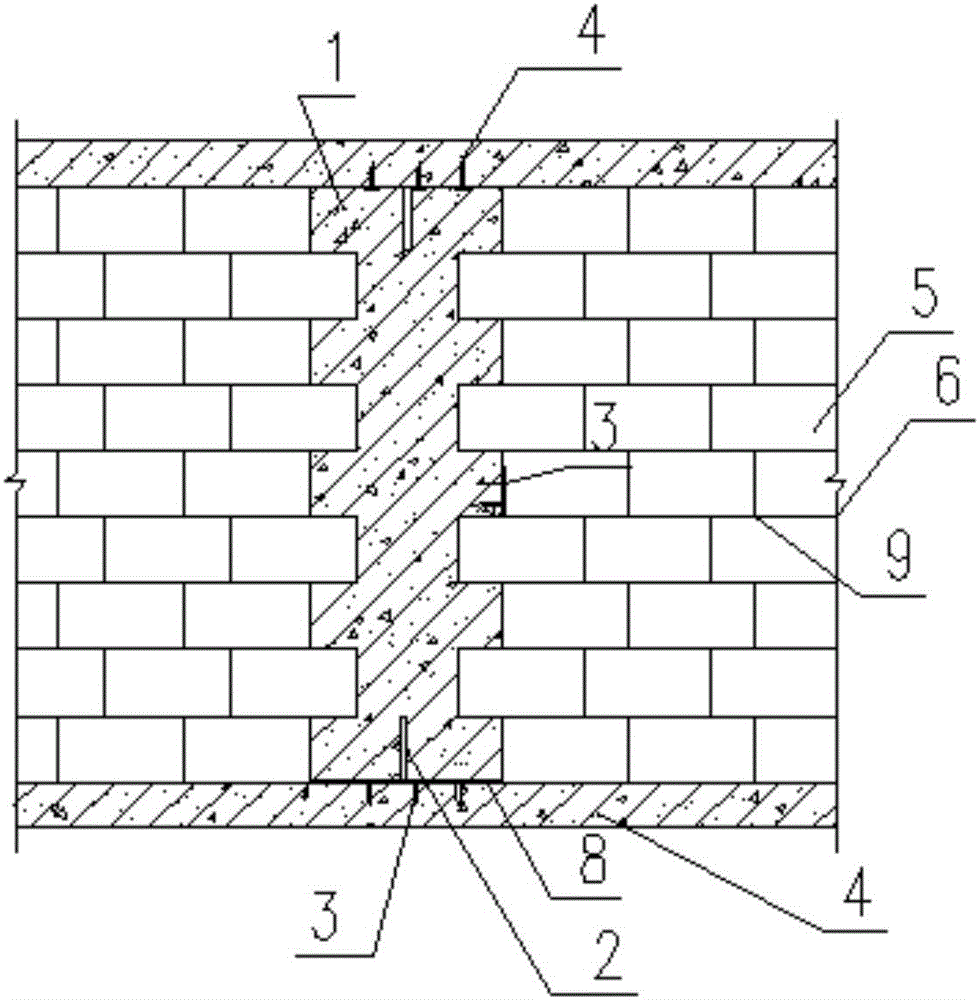

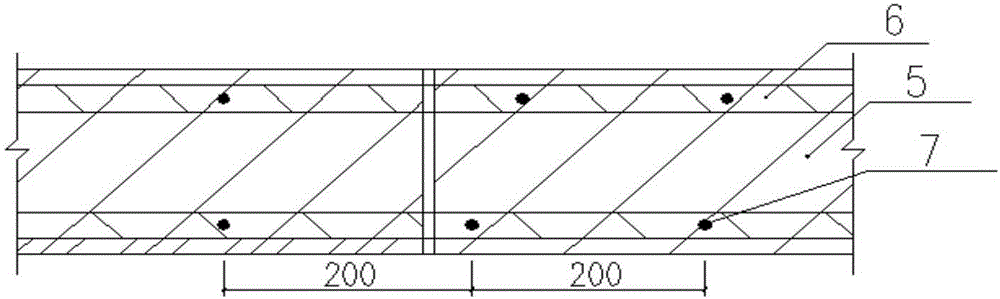

[0031] The assembled reinforced concrete structural column proposed by the present invention is as figure 1 , figure 2 and image 3 As shown, it is prefabricated by reinforced concrete in the factory and set at the specified position of the structure. Including the column 1, the edge connecting the column 1 and the wall is a horse-toothed structure, and the flat iron 6 is arranged in the column 1 to replace the tie bars to realize the connection with the wall, and the two ends of the column 1 are buried There are pipe clips or steel bars 2, and the pipe clips or steel bars 2 are welded together with the steel plate 8, and the steel plate 8 is connected with the upper and lower floors 4 through nails 3.

[0032] Among them, the entire prefabricated reinforced concrete structural column is prefabricated by reinforced concrete, and the wall is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com