Multi-position cutting device for furniture manufacturing

A furniture manufacturing and cutting device technology, which is applied in the field of multi-position cutting devices for furniture manufacturing, can solve problems such as defects in the cleanliness of the multi-position adjustment cutting work surface, and achieve improved operation efficiency and quality, improved moving efficiency, and clean work surfaces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

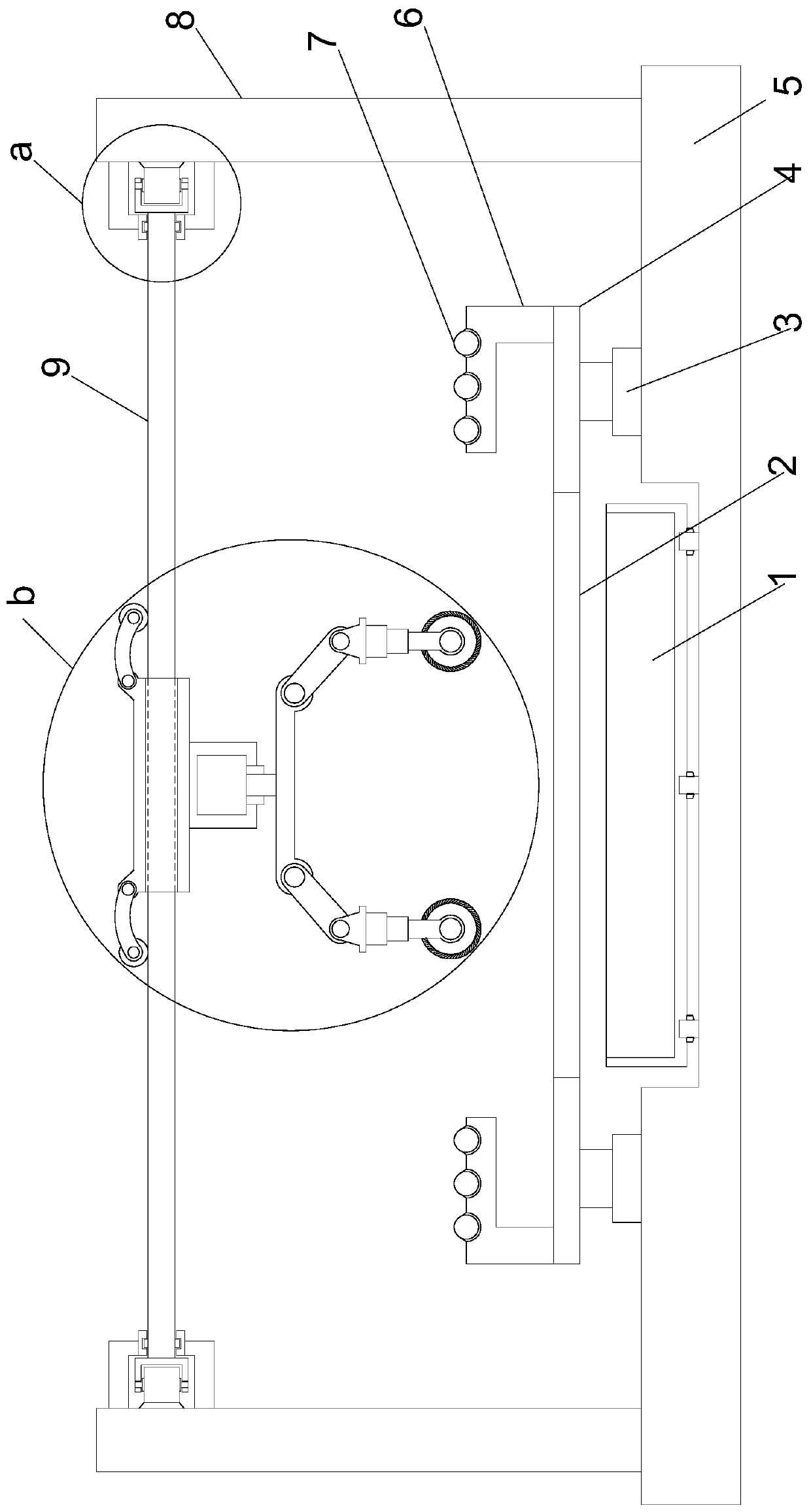

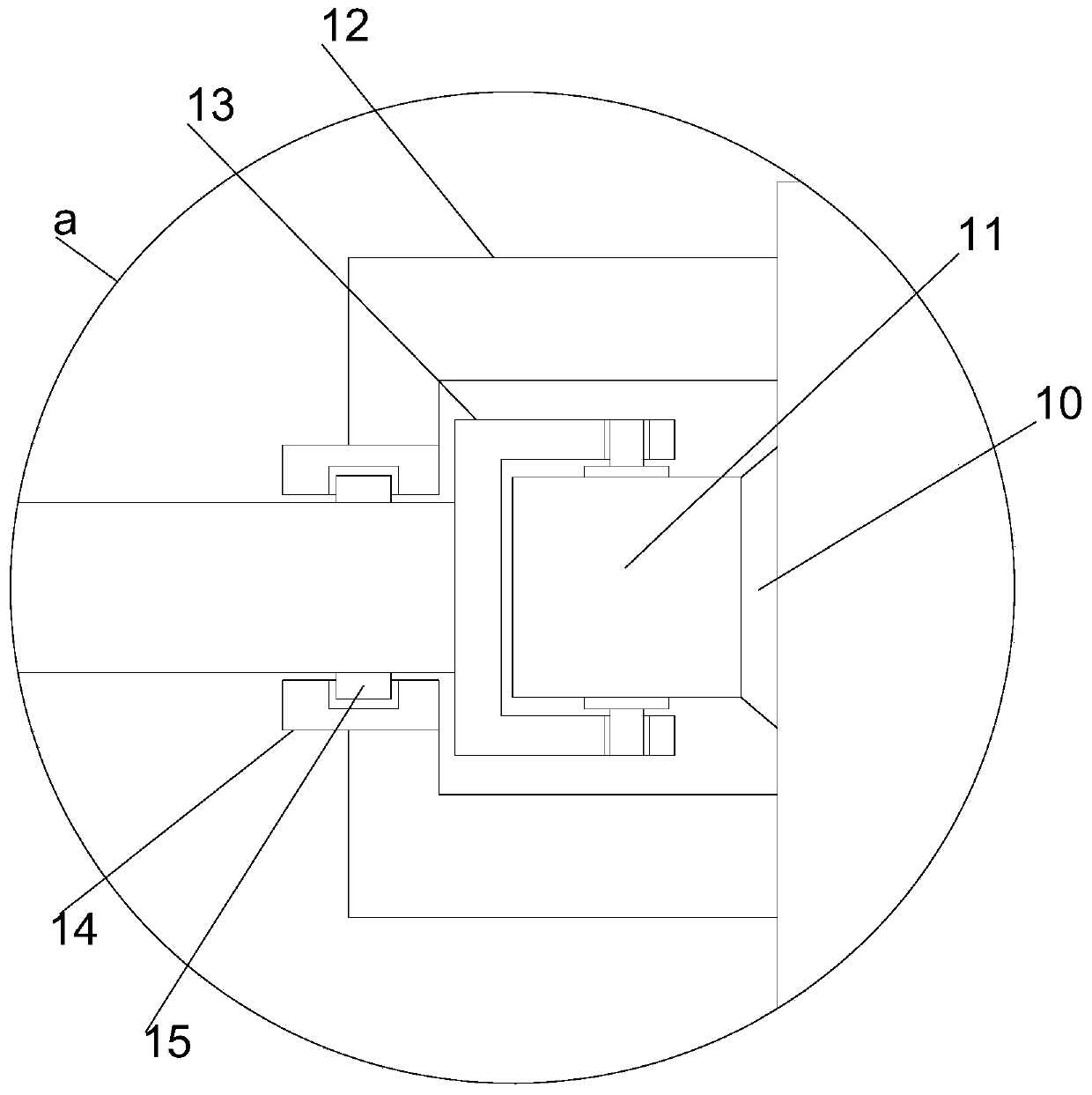

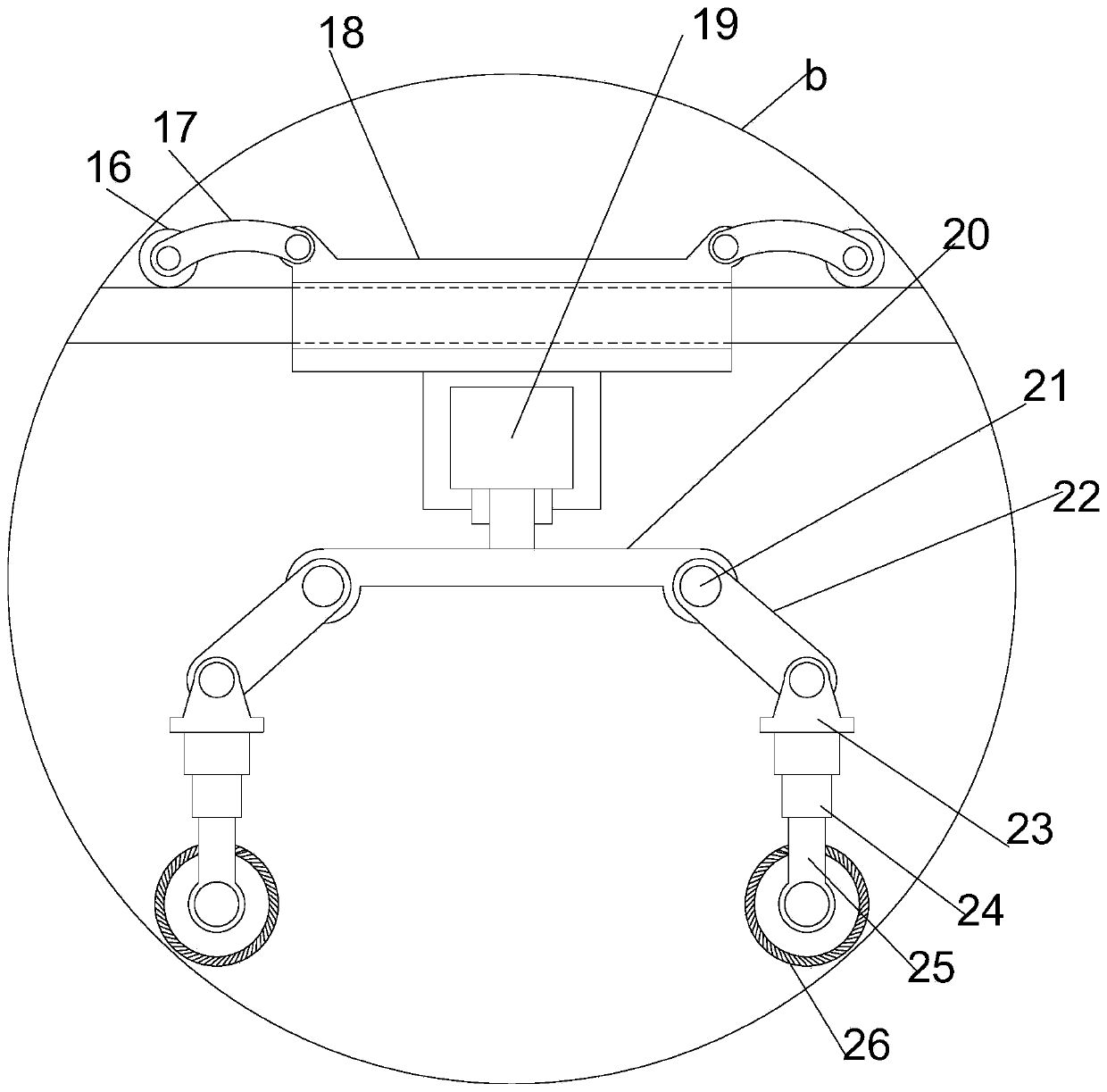

[0022] see Figure 1~4 , in an embodiment of the present invention, a multi-position cutting device for furniture manufacturing includes a horizontally arranged fixed mounting plate 5, and support mounting plates 8 are symmetrically arranged on both ends of the upper side of the fixed mounting plate 5, and the supporting mounting plates 8 are all vertical Setting, between the upper ends of the support mounting plate 8, a mobile guide column 9 is horizontally arranged, and a guide installation frame 12 is longitudinally arranged on the support installation plate 8 facing the two ends of the mobile guide column 9, and the support of the guide installation frame 12 is Mounting plate 8 is provided with moving rack 10 longitudinally, and both ends of moving guide column 9 are provided with driving gear 11 through moving mounting bracket 13, and driving gear 11 is meshed with moving rack 10, and guide mounting frame 12 cooperates to move The guide column 9 is provided with a guide c...

Embodiment 2

[0025] On the basis of Embodiment 1, through the cooperation of the L-shaped material guide frame 6 and the material guide ball 7, the furniture board can be moved quickly, which is convenient for processing and loading and unloading, and the debris generated during processing falls on the material guide through the drop hole 2 On the trolley 1, with the accumulation, the guide trolley 1 is finally taken out to discharge the debris, so as to realize the collection of debris and improve the cleanliness of the working surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com