A synchronous feeding scaffold

A technology for scaffolding and material feeding, which is applied to the accessories of scaffolding, the processing of building materials, construction, etc. It can solve the problems of assembly efficiency, feeding structure, support stability, storage and transportation defects, and imperfect structural design, etc., to achieve simple assembly and assembly High efficiency, strong integration, convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

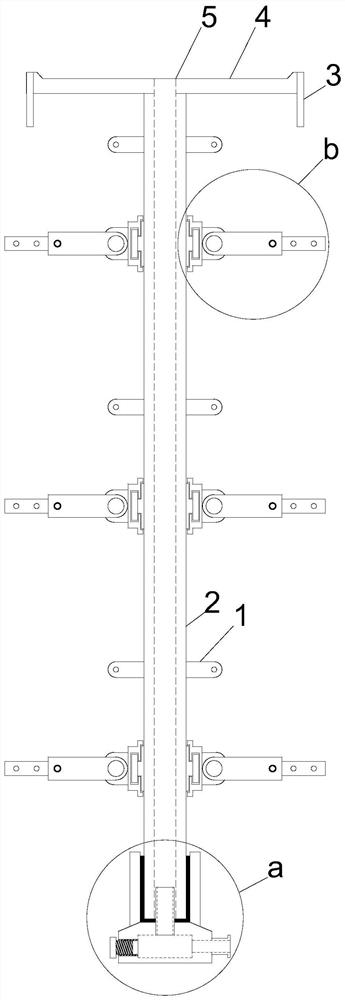

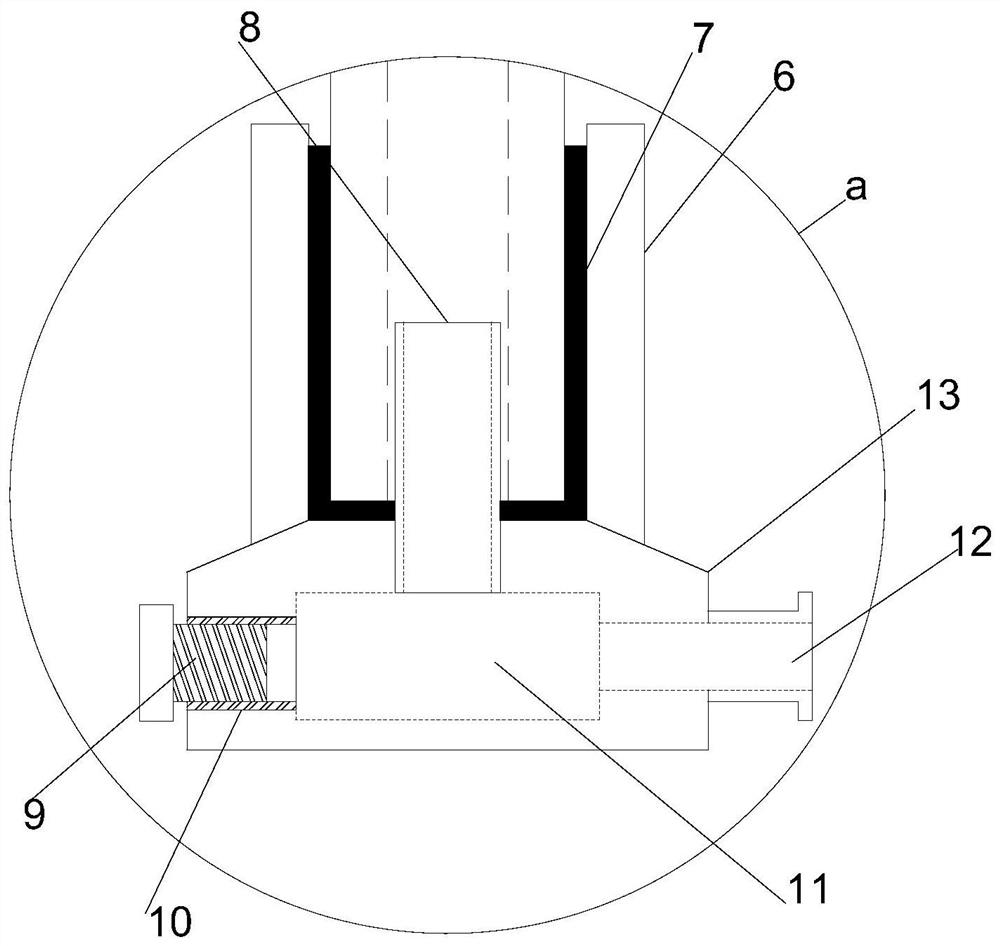

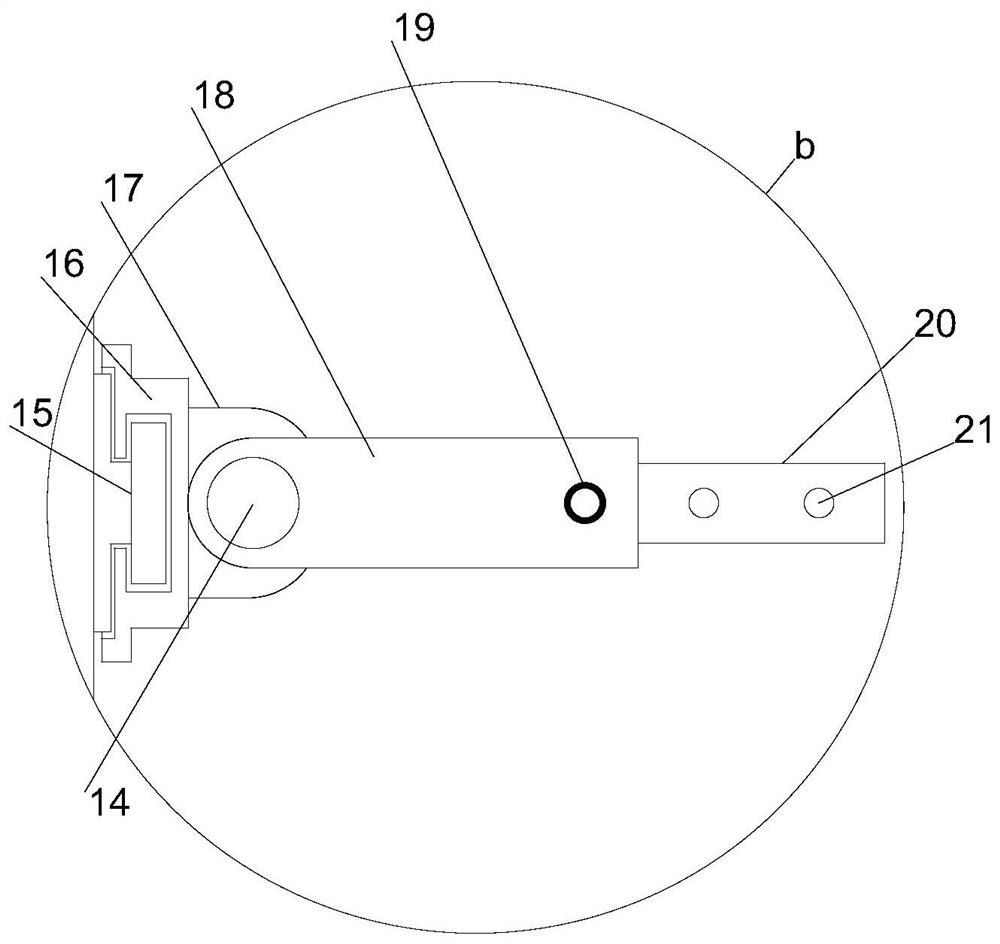

[0022] see Figure 1~4 , in the embodiment of the present invention, a kind of synchronous feeding type scaffolding, comprises vertically arranged support material guide cylinder 2, and the upper end of support material guide cylinder 2 is horizontally provided with support installation plate 4, and support installation plate 4 cooperates support material guide cylinder 2 A discharge hole 5 is provided, and the lower end of the support guide cylinder 2 is vertically provided with a support installation cylinder 6, and the lower end of the support installation cylinder 6 is horizontally provided with a support guide plate 13, and the outer sides of the support guide cylinder 2 are vertically and equally spaced. There are a number of limit rotation rings 15, and limit rotation cylinders 16 are arranged in conjunction with the limit rotation rings 15. The outer sides of the limit rotation cylinders 16 are all symmetrically provided with swing mounts 17, and the swing mounts 17 all...

Embodiment 2

[0025] On the basis of Embodiment 1, when the material feeding is stopped, turn and open the material guide stud 9, so that the mortar in the support material guide cylinder 2 is led out and collected, and then cleansed with clear water, so as to avoid blockage caused by the internal bonding and solidification of the mortar , to ensure the continuous and stable operation of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com