Pouring method for fine aggregate concrete steps of sloping roof

A technology of fine stone concrete and sloping roof, applied in the direction of roof, roof covering, roof using sealing aggregates, etc., can solve the problems of hidden safety hazards, lack of foothold for construction personnel, large concrete area, etc., to improve the construction The effect of quality, low price of materials, and simple on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

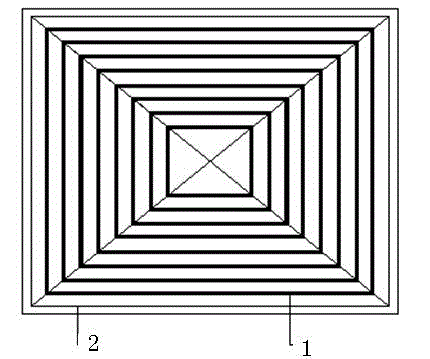

[0011] like figure 1 As shown, the present invention divides the large roof 2 into several small surfaces by using the compartment bar 1 on the base of the large roof. The spacing of each compartment bar is set according to the slope of the inclined roof. The spacing of the bars should be 0.9m; the spacing of each section of the sloping roof with a slope of 30°~45° should be 0.8m; the spacing of each section of the sloping roof with a slope of more than 45° should be 0.6m. After the strength of the sub-bars meets the requirements, the pouring of the fine stone concrete on the inclined roof can be carried out from top to bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com