Room-and-pillar mining method

A mining method and mine house technology, applied in the field of open-field mining method, can solve problems such as the influence of adjacent mine houses, potential safety hazards, and reasonable utilization of unfavorable resources, so as to improve labor productivity, ore recovery rate, and ore pillar distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

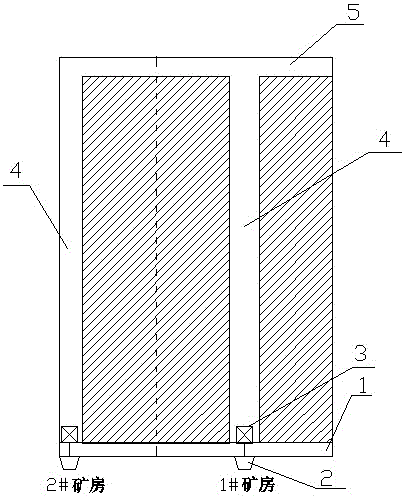

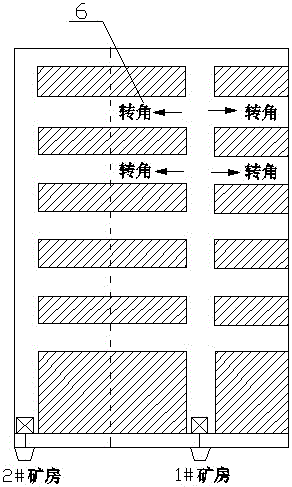

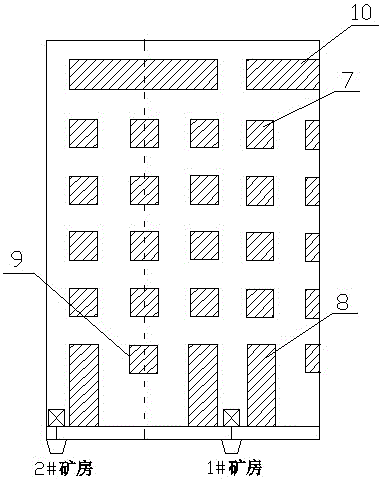

[0027] Such as Figure 1 ~ Figure 3 Shown, my mine xx mining area xx middle section xx ore layer xx ore house adopts the room-and-pillar mining method of the present invention, and the concrete process is as follows:

[0028] a. Excavate the lower horizontal middle roadway 1 along the direction of the ore body. The roadway is 2.5 meters wide and 2 meters high, and is used for outputting ore, and as a pedestrian passage and wind flow passage;

[0029] b. Along the roadway 1 in the lower horizontal middle section, excavate electric rake chamber 2 every 26m, and the specification of electric rake chamber 2 is 3m×2.5m×2m;

[0030] c. Drill about 5m along the direction of the ore seam with 2m×2m to erect the funnel mouth 3 of the mine house and install electric rakes and other related auxiliary equipment;

[0031] d. In the middle of the mining house, the section with a width-to-height ratio of 4m×2m is cut and the upper mountain 4 is connected with the upper horizontal middle roa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com