Heat radiator for V type fuel gas powering and compression integrated machine

A technology of gas power and radiator, which is applied in the cooling of engine components, machines/engines, and engines. It can solve problems such as freezing and cracking of pipelines and valve bodies, failure to meet V-type gas power double cooling, and burning tiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in conjunction with accompanying drawing and specific implementation case:

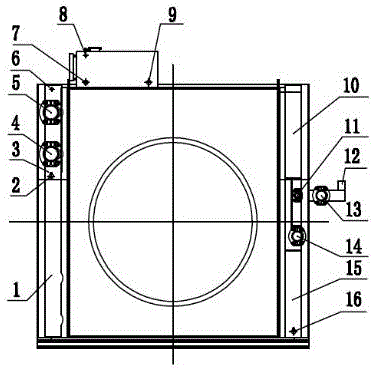

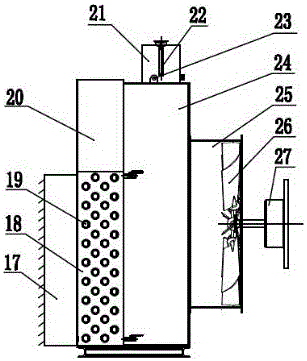

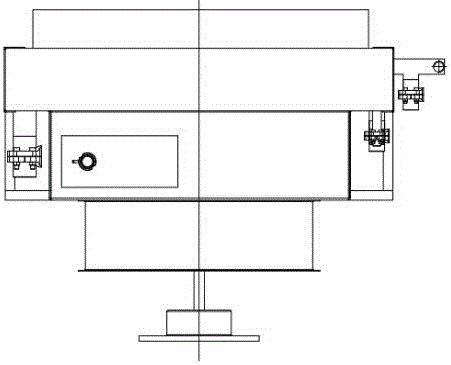

[0021] Such as figure 1 shown, and refer to figure 2 , image 3 , a radiator for a V-type gas power compressor integrated machine, the radiator has a three-stage heat dissipation structure composed of a heat dissipation component, an air guide cover 24 and an air duct 25; The cylinder 25 is arranged in sequence from front to back, and the size of the heat dissipation parts, the wind guide cover 24 and the air cylinder 25 is successively reduced from the front to the back to form a radiator with a three-stage trapezoidal structure; The water radiator 20 and the air cooler 18; the water radiator 20 is welded on the upper part of the air cooler 18; the water tank of the water radiator 20 has a coolant inlet 5, a coolant outlet 4 and a water outlet I2; The cooling liquid inlet 5 is located above the cooling liquid outlet 4, and is connected with the high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com