Efficient water bath skid-mounted shale gas heating furnace and heating method

A shale gas and heating furnace technology, which is applied to air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem that shale gas cannot be used in heating furnaces, and achieve high pressure bearing capacity, high thermal efficiency, and guaranteed Effects of Thermal Expansion and Strength Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

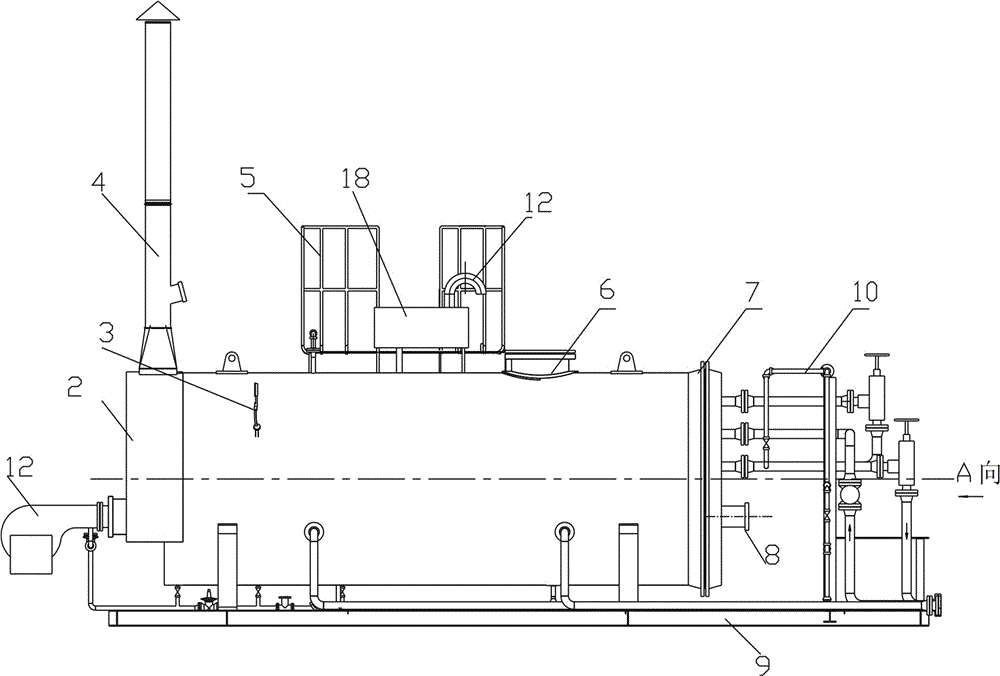

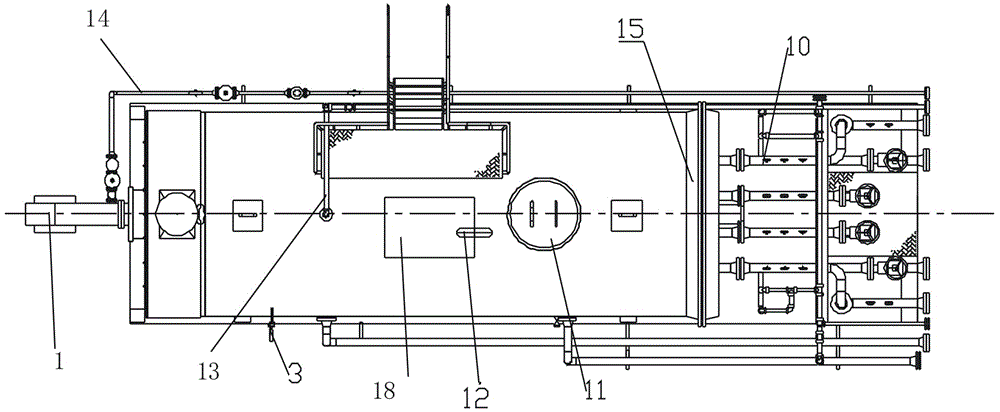

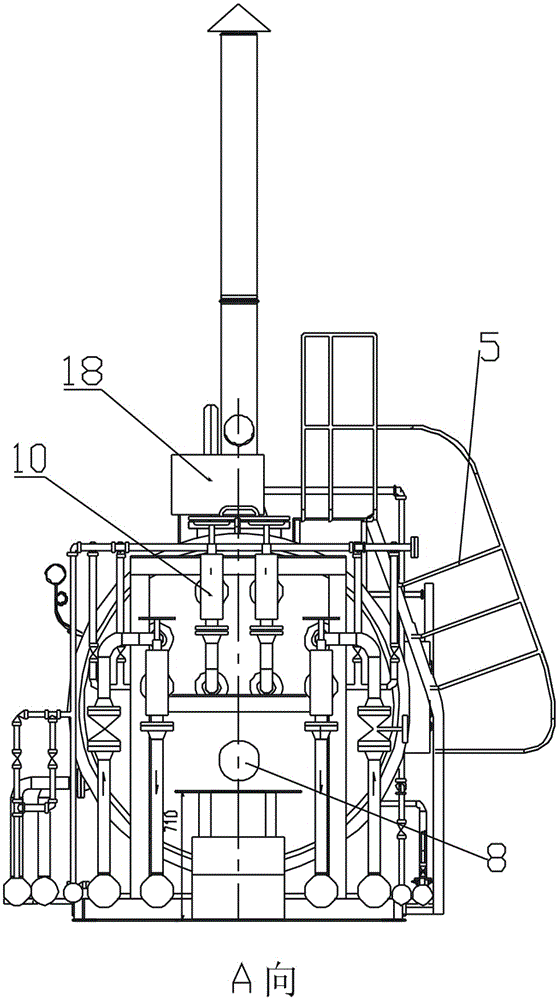

[0041] The high-efficiency water-bath skid-mounted shale gas heating furnace developed according to the present invention includes a heating furnace body 7 and a combustion cylinder 7-4 in the furnace. 9 is set as a whole; the horizontal end of the furnace body 7 is the fuel gas inlet end, and the other end is the rock gas pipeline interface end; The inner cavity is a water-filled space 20;

[0042] At the combustion gas inlet end, a combustion device 1 is arranged on the outside of the combustion cylinder 7-4, and the fuel gas inlet pipe 14 communicates with the ignition end of the combustion device 1; one end of the fire cylinder 7-4 is connected to the combustion device 1, and the other end is connected to the smoke The pipe 19 and the smoke pipe 19 are connected with the smoke box 2 and the chimney 4 in turn;

[0043] At the interface end of the rock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com