Engine air inlet assembly, engine system and method for preventing engine air inlet pipe from accumulating large ice blocks

A technology of air intake components and engines, which is applied in the direction of engine components, machines/engines, charging systems, etc., and can solve problems that affect car driving performance and car safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The engine air intake assembly, the engine system and the method for preventing the accumulation of large ice cubes in the engine air intake pipe according to the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments, but the detailed description does not constitute a definition of the present invention. Technical Program Limitations.

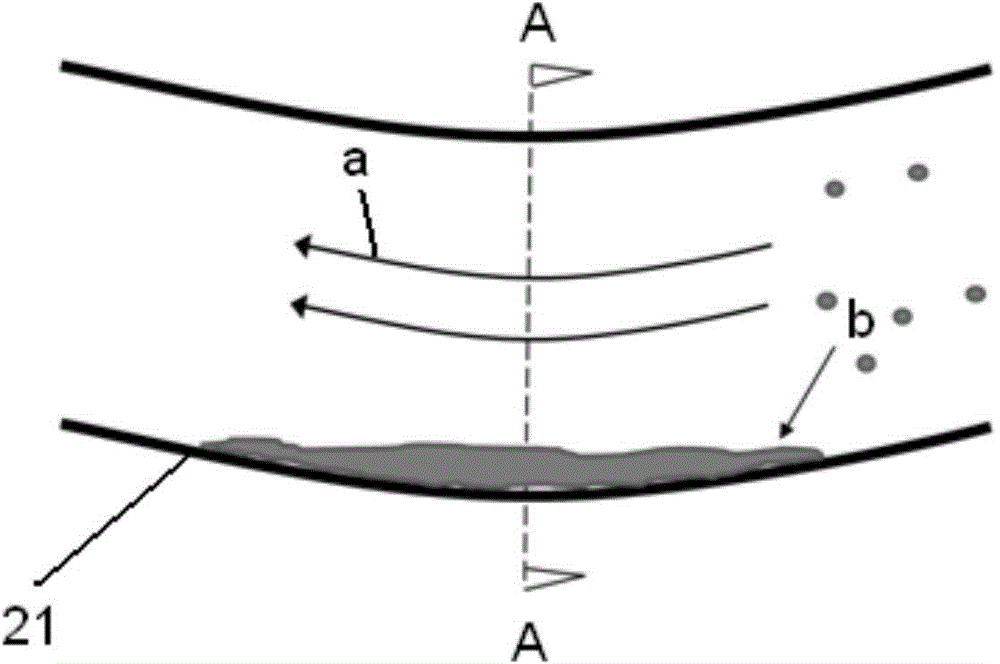

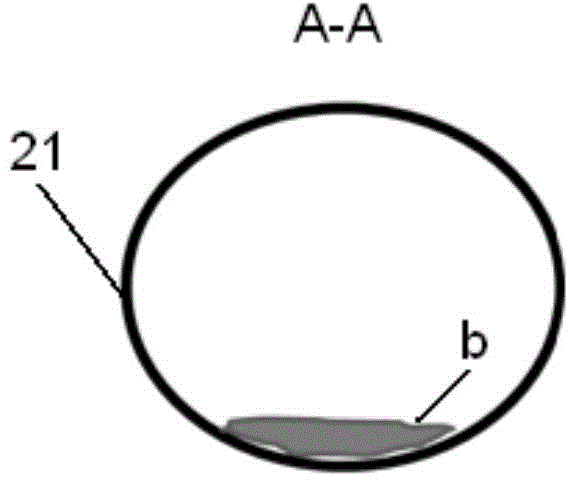

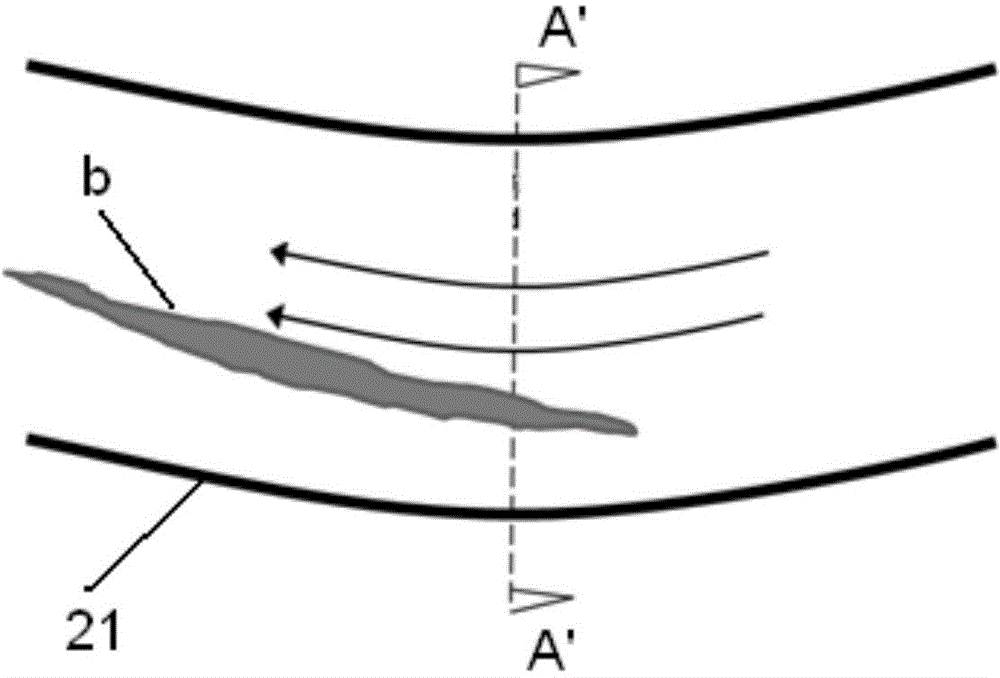

[0083] Figure 5 to Figure 8 The structure and state of the engine intake assembly described in the present invention in one embodiment are respectively shown.

[0084] like Figure 5 to Figure 8 As shown, in the above embodiment, the engine intake assembly includes the engine intake pipe 10 and the heating device 30, wherein, along the gas a flow direction X of the engine intake pipe 10, the engine intake pipe 10 has an intake port 11 and The air outlet port 12 is provided with an ice cube trapping structure 13 at the bottom of the engine intake pipe 10, and the ic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com