Crankshaft for refrigeration compressor

A technology for refrigeration compressors and crankshafts, applied in the field of crankshafts, can solve problems such as oil film instability, roughening, and oil film damage, and achieve the effects of reducing roughening failures, avoiding roughening, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

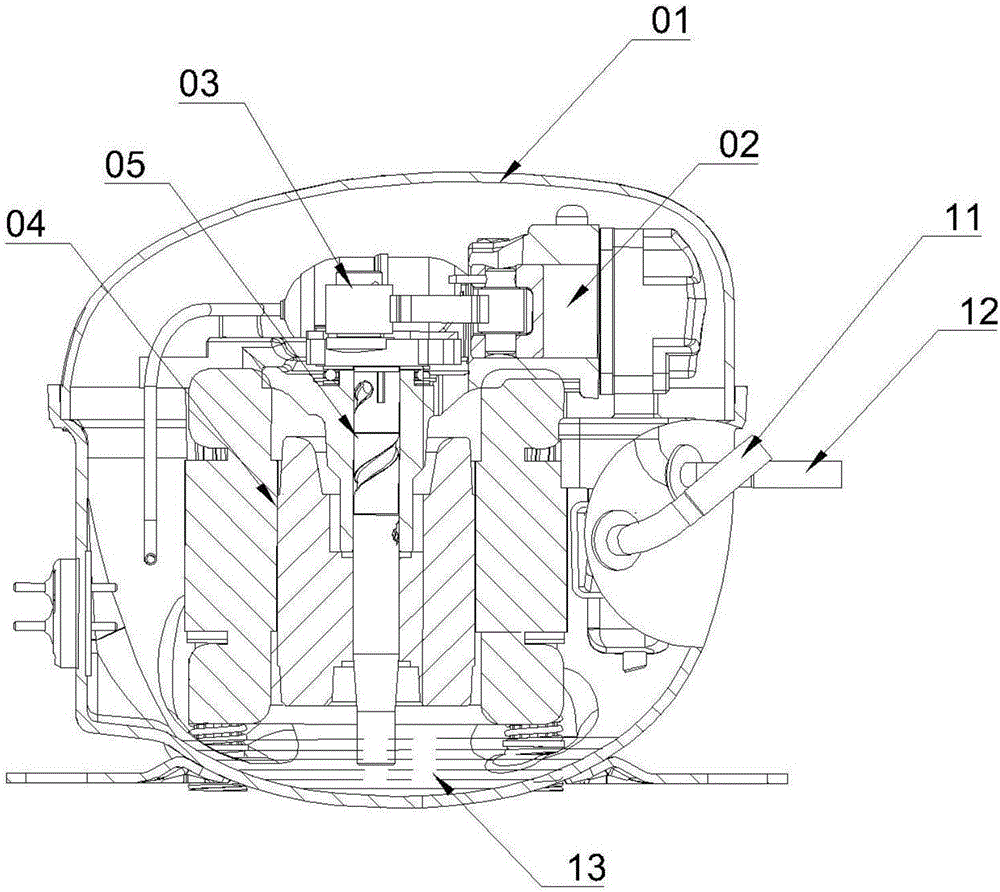

[0014] like figure 1 As shown in , the refrigeration compressor adopting the crankshaft of the present invention includes a closed casing 01, a piston-cylinder unit 02, a crankshaft-connecting rod mechanism 03 and a motor unit 04. The shell 01 is provided with a suction pipe 11 and an exhaust pipe 12. The refrigerant enters the piston-cylinder unit 02 through the suction pipe 11, and the motor unit 04 drives the crankshaft-connecting rod mechanism 03, driving the piston-cylinder unit 02 to reciprocate. The compressed refrigerant is discharged from the compressor shell 01 through the discharge pipe 12 .

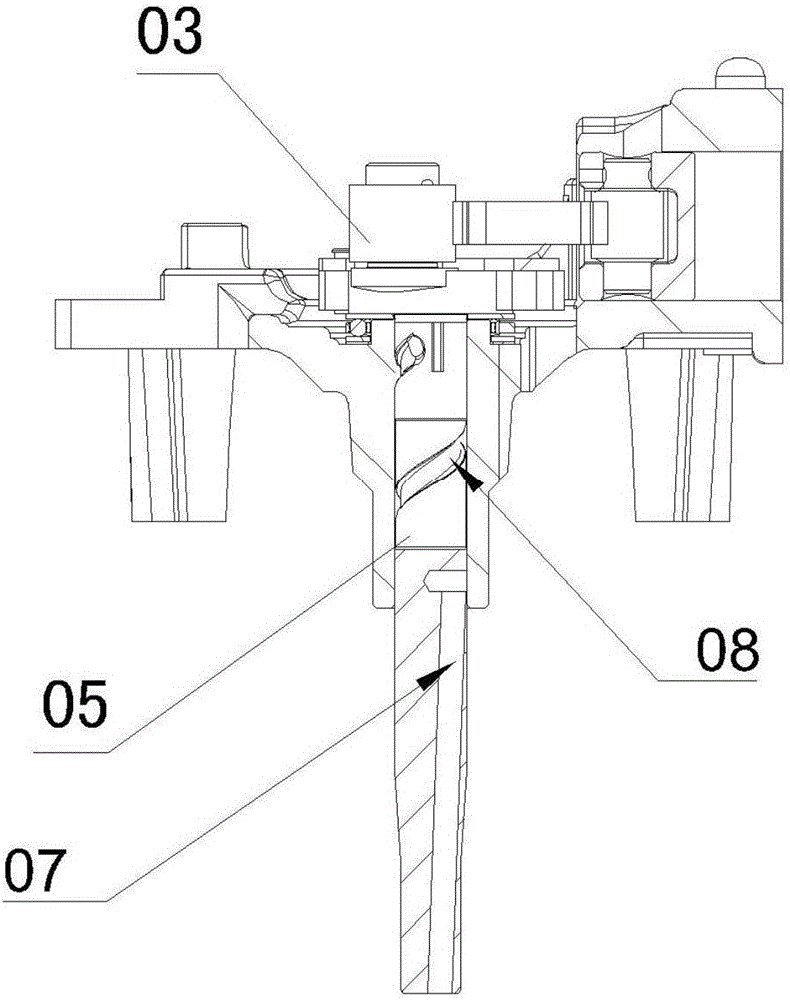

[0015] Please also see figure 2 The crankshaft 05 of the present invention in the crankshaft-connecting rod structure 03 includes a centrifugal pump 07 and a viscous pump 08. The centrifugal pump 07 can be integral or pressed into the oil suction pipe, and the refrigerating oil 13 is transported upwards by centrifugal action.

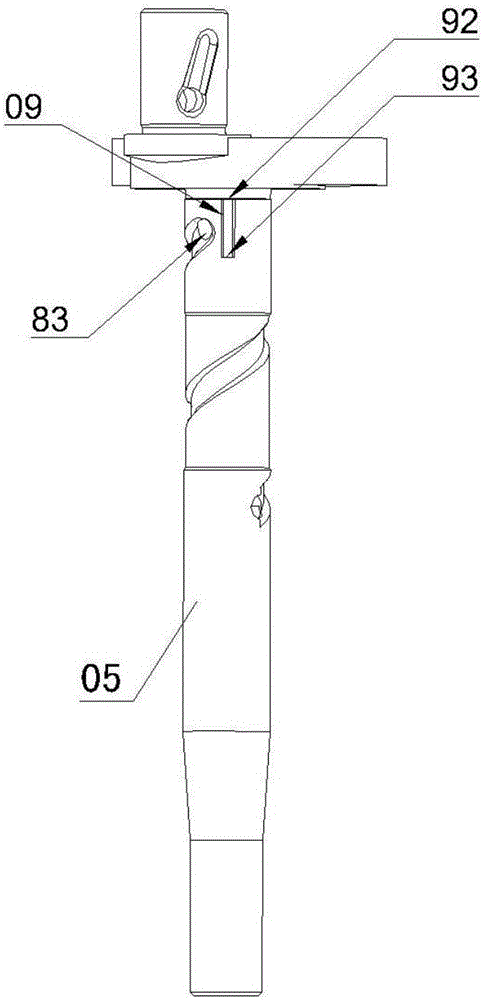

[0016] like image 3 and Figure 4 As shown,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap