Vibration-preventing equalizer pipe of water turbine

A technology of hydraulic turbines and pressure equalizing pipes, which is applied to pipe components, siphon pipes, mechanical equipment, etc., can solve problems such as stress concentration in pipes, and achieve the effects of improved safety factor, convenient disassembly and assembly, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

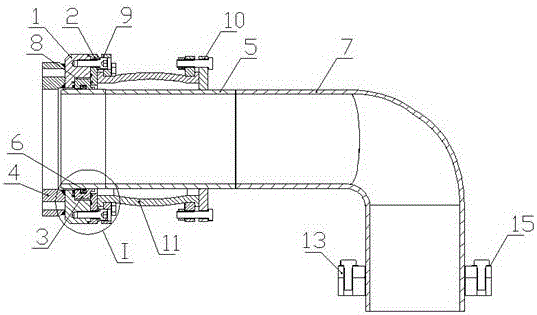

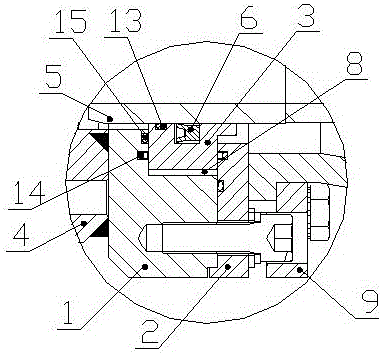

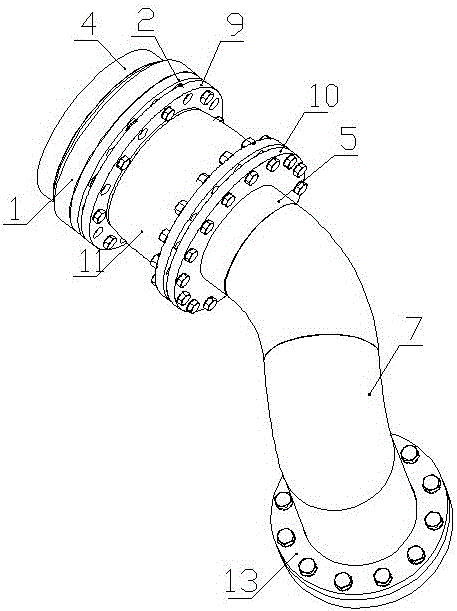

[0031] Such as Figure 1-3 As shown, the anti-vibration pressure equalizing pipe of the water turbine includes an expansion joint 5, a pipe body 7 and a radial anti-vibration connector for connecting with the lining flange 4, the expansion joint 5 is fixedly connected with the pipe body 7, and the The radial anti-vibration connector is arranged on the expansion joint 5 .

[0032] When the water turbine unit is running, the water turbine unit vibrates, and the pipe body 7 also vibrates and moves axially and radially. Since the expansion joint 5 provided on the pipe body 7 has the function of expanding and contracting along the length direction of the pipe body 7, the expansion joint 5 One end of the expansion joint 5 is fixed on the pipe body 7 and expands and contracts back and forth correspondingly with the vibration. The other end of the expansion joint 5 is provided with a radial anti-vibration connector, and the end of the expansion joint 5 arranged in the radial anti-vibr...

Embodiment 2

[0034] Such as Figure 1-3 As shown, the anti-vibration pressure equalizing pipe of the water turbine includes an expansion joint 5, a pipe body 7 and a radial anti-vibration connector for connecting with the lining flange 4, the expansion joint 5 is fixedly connected with the pipe body 7, and the The radial anti-vibration connector is arranged on the expansion joint 5 .

[0035] The radial anti-vibration connector includes a connection flange and a support ring 3, the support ring 3 is fixed on the expansion joint 5, the support ring 3 is assembled on the connection flange, and the radial anti-vibration connector passes through The connecting flange is connected with the lining flange 4.

[0036] The connecting flange includes a supporting flange 1 and a supporting ring matching flange one 2, the supporting flange 1 and supporting ring matching flange one 2 are connected together, and a groove 8 is provided, and the supporting ring 3 is assembled In the groove 8 , there is ...

Embodiment 3

[0041] Such as Figure 1-3 As shown, the anti-vibration pressure equalizing pipe of the water turbine includes an expansion joint 5, a pipe body 7 and a radial anti-vibration connector for connecting with the lining flange 4, the expansion joint 5 is fixedly connected with the pipe body 7, and the The radial anti-vibration connector is arranged on the expansion joint 5 .

[0042] The radial anti-vibration connector includes a connection flange and a support ring 3, the support ring 3 is fixed on the expansion joint 5, the support ring 3 is assembled on the connection flange, and the radial anti-vibration connector passes through The connecting flange is connected with the lining flange 4.

[0043] The connecting flange includes a supporting flange 1 and a supporting ring matching flange one 2, the supporting flange 1 and supporting ring matching flange one 2 are connected together, and a groove 8 is provided, and the supporting ring 3 is assembled In the groove 8 , there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com