An anti-eccentric abrasion pipe cleaner

A technology for pigs and bases, which is applied to special pipes, pipe components, pipes/pipe joints/fittings, etc., can solve problems such as partial wear of pipe pigs, and achieve prevention of partial wear, stable operation, and strong passability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

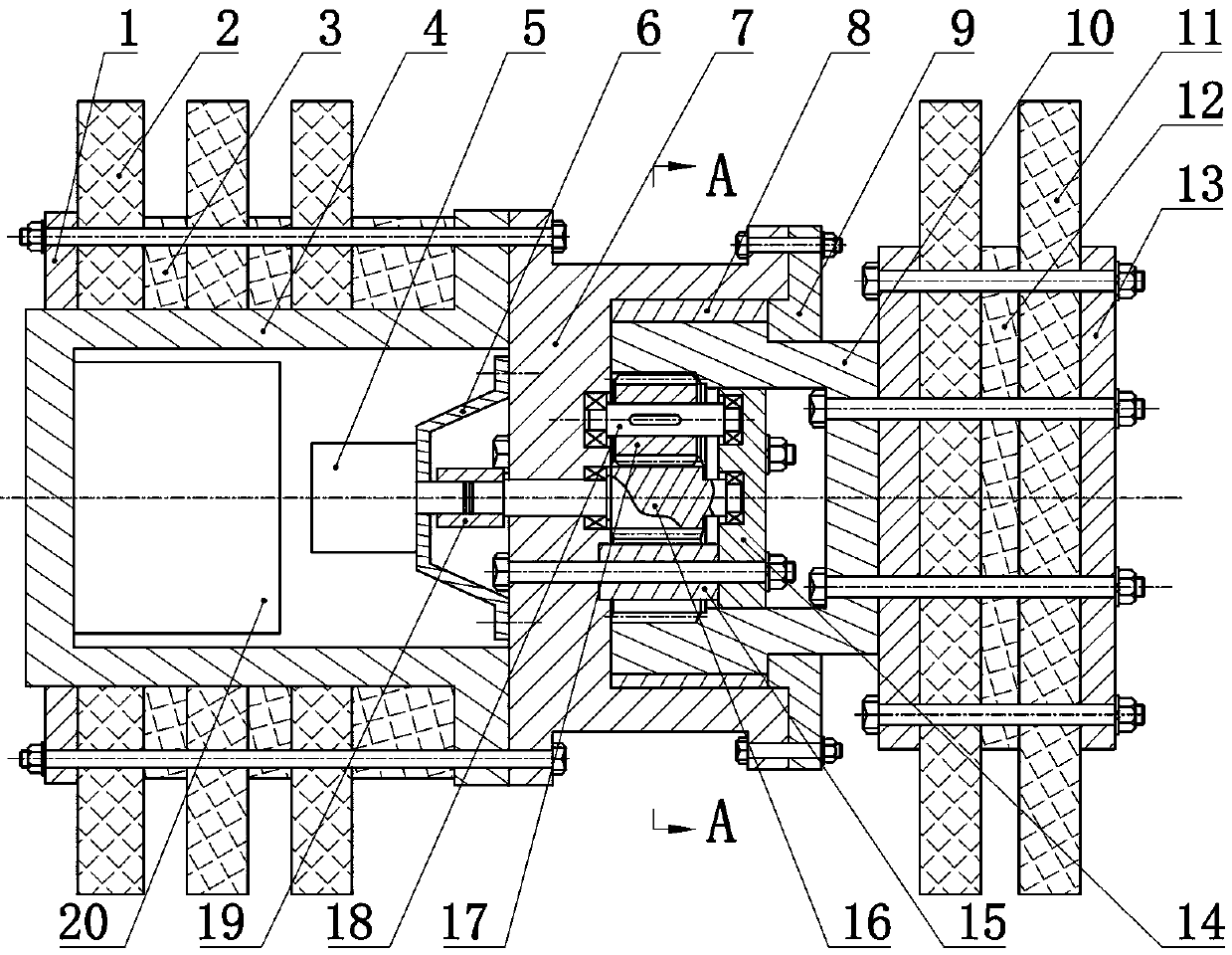

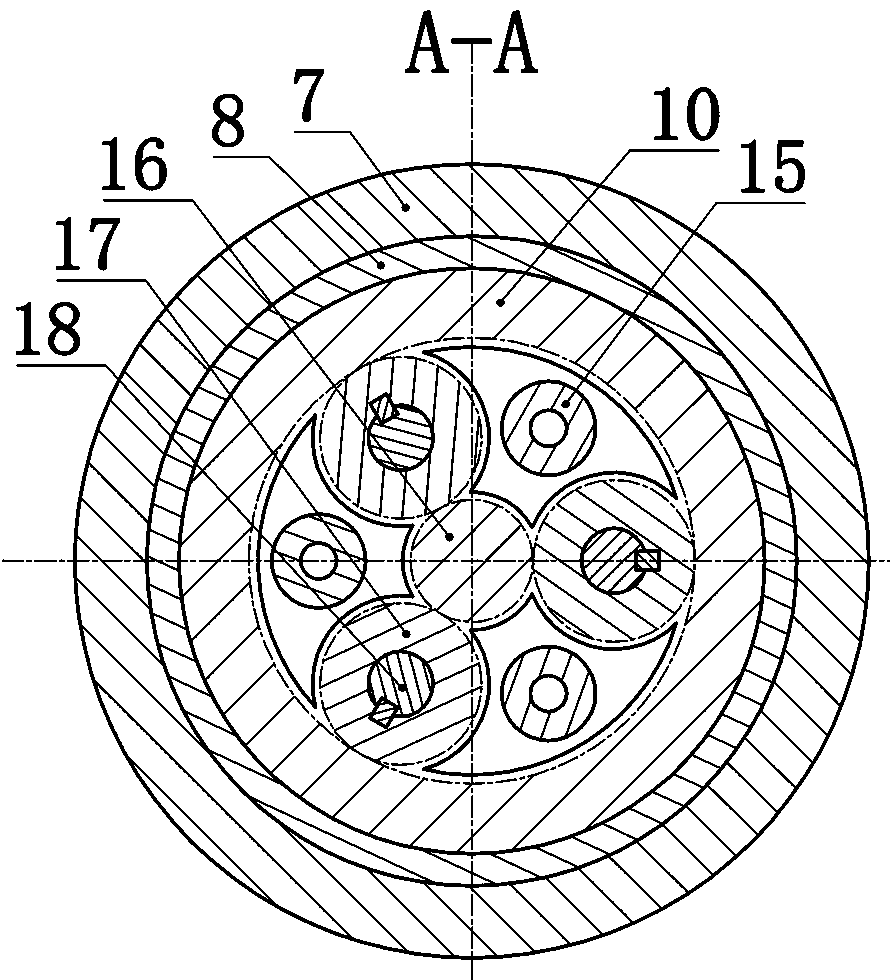

[0016] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 , figure 2 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0017] The main body of the base 7 is cylindrical, the main body of the rotating sleeve 10 is cylindrical, the rotating sleeve 10 is set inside the base 7, and the sliding bearing 8 is arranged between the base 7 and the rotating sleeve 10 . A step is provided in the middle of the swivel sleeve 10, and the collar 9 cooperates with the step of the swivel sleeve 10 and axially fixes the swivel sleeve 10, and connects the collar 9 and the base 7 with bolts.

[0018] The pressing plate 14 is disc-shaped and arranged in the rotating sleeve 10 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com