Power air-heating furnace

A technology of hot blast stove and electric power, which is applied in the direction of air heater, fluid heater, lighting and heating equipment, etc. It can solve the problems of air pollution, different humidity of grain, and different heat requirements of hot blast stove, etc., and achieves convenient operation and low cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

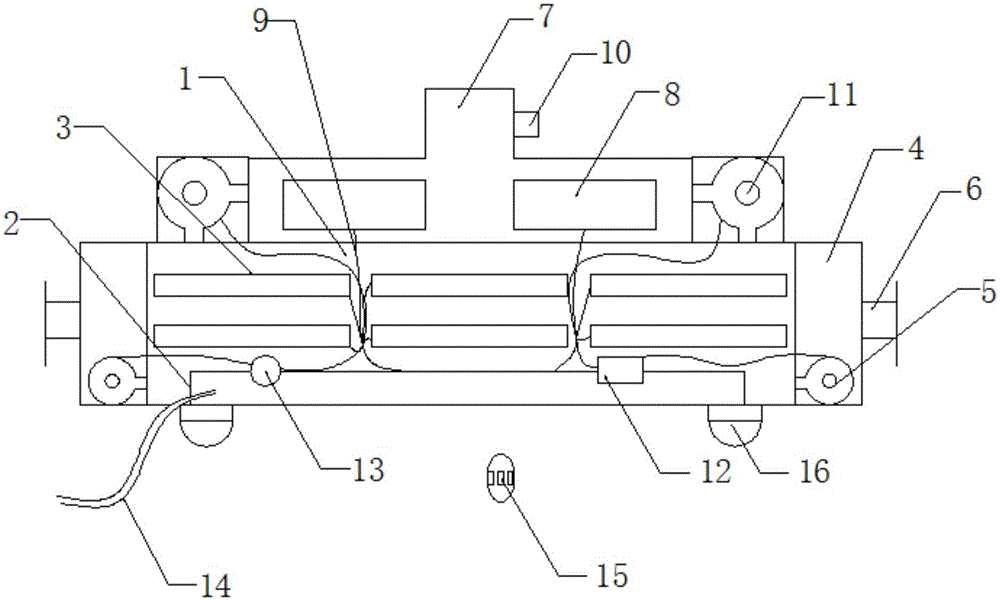

[0018] Example: such as figure 1 As shown, the present invention provides an electric hot blast stove, including a heating chamber 1, a central controller 2, a heater 3, an air buffer chamber 4, an exhaust fan a5, an air inlet 6, a hot gas chamber 7, an electric heater 8, a wire 9, Hot air outlet 10, exhaust fan b11, signal receiver 12, switch button 13, power cord 14, remote controller 15 and universal wheel 16, the inside of heating chamber 1 is provided with central controller 2 and several heaters 3, heating chamber One end of 1 is provided with an air buffer chamber 4, and one end of the air buffer chamber 4 is provided with an air inlet 6, the inside of the air buffer chamber 6 is provided with an exhaust fan a5, the top of the heating chamber 1 is provided with an exhaust fan b11, and the top of the heating chamber 1 A hot gas chamber 7 is provided, and several electric heaters 8 are arranged inside the hot gas chamber 7. One end of the hot gas chamber 8 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com