A kind of mahogany drying method

A technology of mahogany and drying equipment, which is applied in drying, wood drying, drying of solid materials, etc., can solve the problems of uneven high-frequency current, low oil content, regardless of control of oil content, etc., and is conducive to uniform distribution, Heating uniformly, ensuring uniform drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

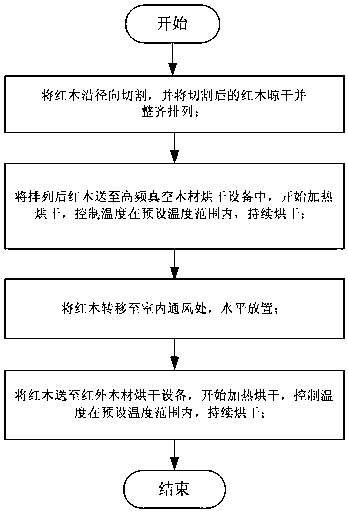

[0022] Below in conjunction with accompanying drawing, further elaborate the present invention.

[0023] Such as figure 1 Shown, mahogany drying method of the present invention comprises the following steps:

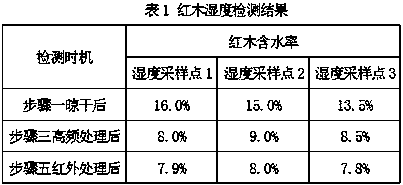

[0024] Step 1: first cut the mahogany into rectangular strips in the radial direction, and the direction of the rectangular strips is consistent with the radial direction of the tree, so that the radial fibers of the mahogany are less damaged, which is used as a channel for the subsequent mahogany to adjust the internal moisture; carry out drying treatment, Control the moisture content of wood to 13% to 18%.

[0025] Step 2: Arrange the mahogany wood cut into rectangular strips in a layered right-angled manner to build a cuboid-shaped mahogany stack; fill the gaps between the mahogany with sawdust to make the conduction more uniform after subsequent high-frequency energization; consider In the next link, the medium and high frequency signal penetration ability is small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com