Recyclable PC-ABS plastic building template

A PC-ABS, ABS plastic technology, applied in the field of building formwork, can solve the problems of poor mechanical properties, inability to reuse, damage to building formwork, etc., achieve high bending strength, improve utilization rate, and avoid aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

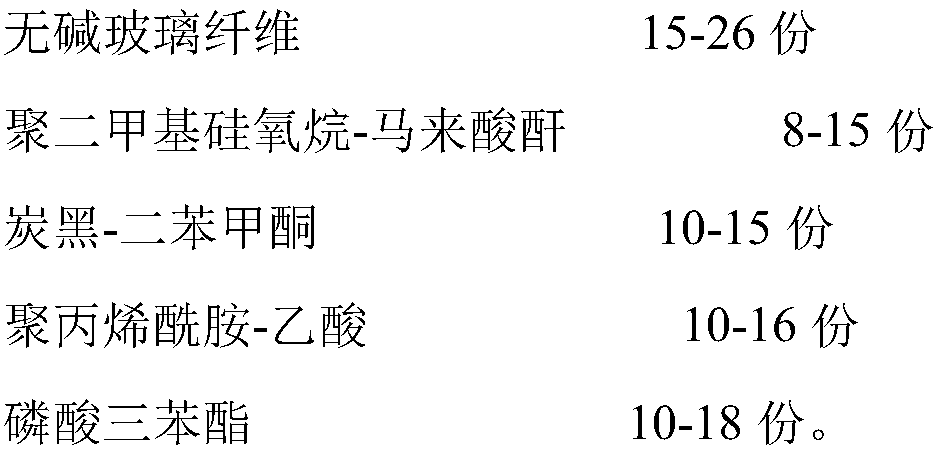

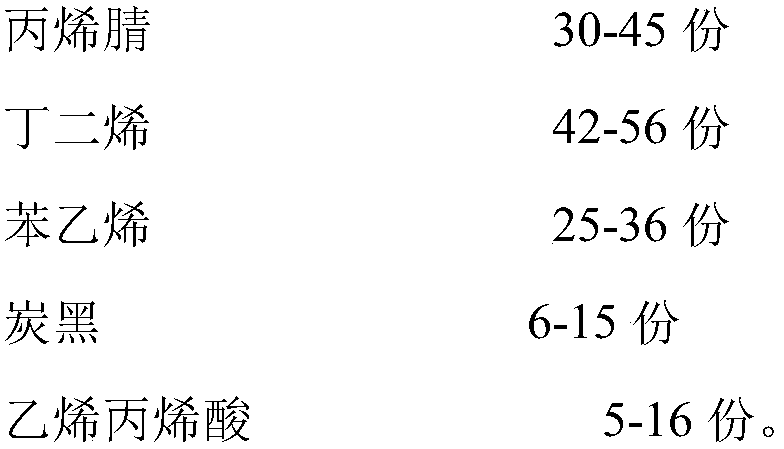

Method used

Image

Examples

Embodiment 1

[0054] The preparation method of carbon black modified ABS plastic comprises the steps:

[0055] (1) Preheat 45 parts of acrylonitrile, 56 parts of butadiene and 25 parts of styrene at a temperature of 70 for 2.5 hours;

[0056] (2) Mix 45 parts of acrylonitrile, 56 parts of butadiene, 36 parts of styrene, 25 parts of carbon black, and 16 parts of ethylene acrylic acid in step (1) and add them into an injection molding machine with an injection temperature of 210°C for injection molding , and then kneaded and granulated by a twin-screw extruder.

[0057] The preparation method of carbon black-benzophenone comprises the steps:

[0058] (1) 8 parts of benzophenone are dissolved in 14 parts of dehydrated alcohol to obtain benzophenone-dehydrated ethanol solution;

[0059] (2) 10 parts of carbon black were ultrasonically obtained in 20 parts of absolute ethanol for 50 min to obtain a carbon black-dehydrated alcohol dispersion;

[0060] (3) Mix the benzophenone-dehydrated ethano...

Embodiment 2

[0074] The preparation method of carbon black modified ABS plastic comprises the steps:

[0075] (1) Preheat 40 parts of acrylonitrile, 51 parts of butadiene and 31 parts of styrene at a temperature of 80° C. for 2 hours;

[0076] (2) Mix 40 parts of acrylonitrile, 51 parts of butadiene, 31 parts of styrene, 20 parts of carbon black, and 14 parts of ethylene acrylic acid in step (1) and add them into an injection molding machine with an injection temperature of 210°C for injection molding , and then kneaded and granulated by a twin-screw extruder.

[0077] The preparation method of carbon black-benzophenone comprises the steps:

[0078] (1) 6 parts of benzophenone are dissolved in 12 parts of dehydrated alcohol to obtain benzophenone-dehydrated ethanol solution;

[0079] (2) 8 parts of carbon black were ultrasonically obtained in 18 parts of absolute ethanol for 45 min to obtain a carbon black-dehydrated alcohol dispersion;

[0080] (3) Mix the benzophenone-dehydrated ethan...

Embodiment 3

[0094] The preparation method of carbon black modified ABS plastic comprises the steps:

[0095] (1) Preheat 38 parts of acrylonitrile, 50 parts of butadiene and 30 parts of styrene at a temperature of 70 for 1 hour;

[0096] (2) Mix 38 parts of acrylonitrile, 50 parts of butadiene, 30 parts of styrene, 18 parts of carbon black, and 13 parts of ethylene acrylic acid in step (1) and add them into an injection molding machine with an injection temperature of 200°C for injection molding , and then kneaded and granulated by a twin-screw extruder.

[0097] The preparation method of carbon black-benzophenone comprises the steps:

[0098] (1) 5 parts of benzophenone are dissolved in 13 parts of dehydrated alcohol to obtain benzophenone-dehydrated ethanol solution;

[0099] (2) 7 parts of carbon black were ultrasonically obtained in 18 parts of absolute ethanol for 40 min to obtain a carbon black-dehydrated alcohol dispersion;

[0100] (3) Mix the benzophenone-dehydrated ethanol so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com